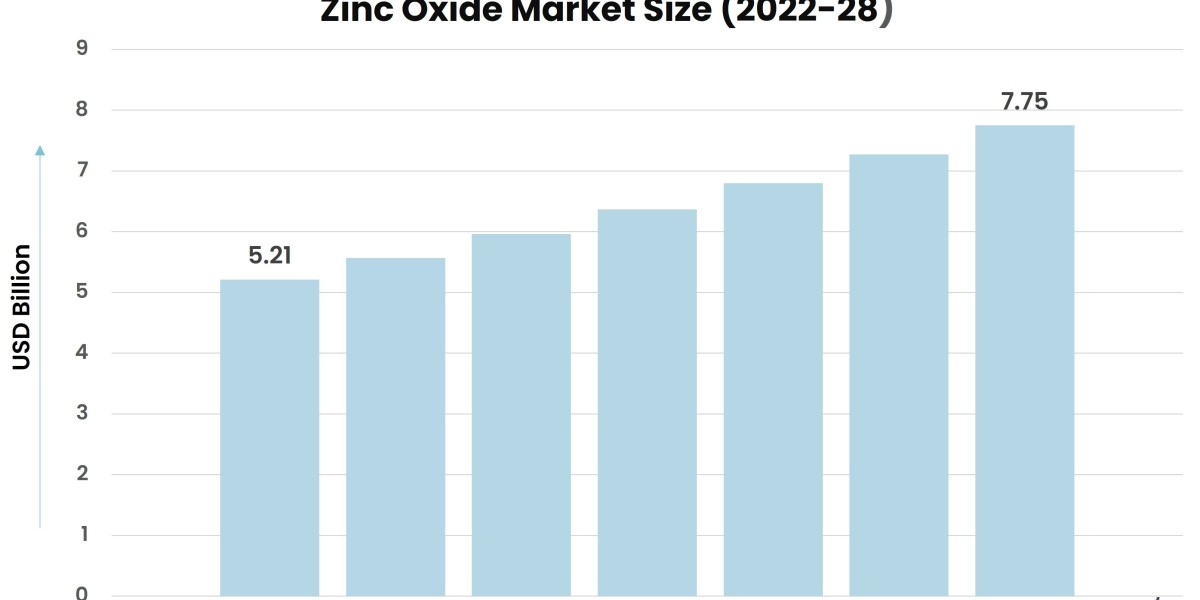

According to Stratview Research, the zinc oxide market was estimated at USD 5.21 billion in 2022 and is likely to grow at a CAGR of 6.82% during 2023-2028 to reach USD 7.75 billion in 2028.

Zinc oxide, a versatile compound with a long history of use, has emerged as a critical ingredient in various industries due to its unique properties and wide-ranging applications. While zinc oxide is commonly associated with sunscreens for its UV-blocking properties, its utility extends far beyond skincare products. From ceramics to rubber manufacturing, textiles to electronics, zinc oxide plays a vital role in enhancing product performance and functionality across diverse sectors. In this article, we explore the multifaceted applications of zinc oxide, highlighting its versatility and importance in different industries.

Sunscreen: Providing Broad-Spectrum UV Protection Zinc oxide's most well-known application is in sunscreens, where it serves as a physical UV filter, providing broad-spectrum protection against both UVA and UVB rays. Unlike chemical sunscreen ingredients that absorb UV radiation, zinc oxide works by reflecting and scattering UV rays away from the skin's surface, reducing the risk of sunburn, premature aging, and skin cancer.

One of the key advantages of zinc oxide in sunscreens is its gentle and non-irritating nature, making it suitable for sensitive skin types, including children and individuals with allergies or skin conditions. Additionally, zinc oxide offers immediate and long-lasting protection without the need for chemical stabilizers, making it an ideal choice for consumers seeking safe and effective sun protection.

Ceramics: Enhancing Glaze Properties and Performance In the ceramics industry, zinc oxide serves as a versatile additive that enhances the properties and performance of ceramic materials. Zinc oxide acts as a fluxing agent, reducing the melting point of ceramic compounds and facilitating the formation of a glassy matrix during firing. This results in improved adhesion, durability, and aesthetic appeal of ceramic products such as tiles, tableware, and sanitaryware.

Furthermore, zinc oxide contributes to the opacity, brightness, and color stability of ceramic glazes, allowing for the creation of vibrant and visually appealing surfaces. Its ability to control the flow and viscosity of molten glazes also enables precise application and uniform coverage, ensuring consistent and high-quality finishes in ceramic production.

Rubber Manufacturing: Vulcanizing Rubber Compounds Zinc oxide plays a crucial role in the rubber industry as a key ingredient in the vulcanization process, which imparts desirable properties to rubber compounds such as strength, elasticity, and resistance to heat, abrasion, and aging. During vulcanization, zinc oxide reacts with sulfur and accelerators to form cross-links between rubber polymer chains, creating a three-dimensional network that enhances the mechanical and chemical properties of rubber products.

Rubber products such as tires, conveyor belts, hoses, seals, and gaskets rely on zinc oxide for their performance and durability in diverse applications and operating conditions. Additionally, zinc oxide helps prevent premature degradation and deterioration of rubber materials, prolonging their lifespan and ensuring reliable performance in demanding environments.

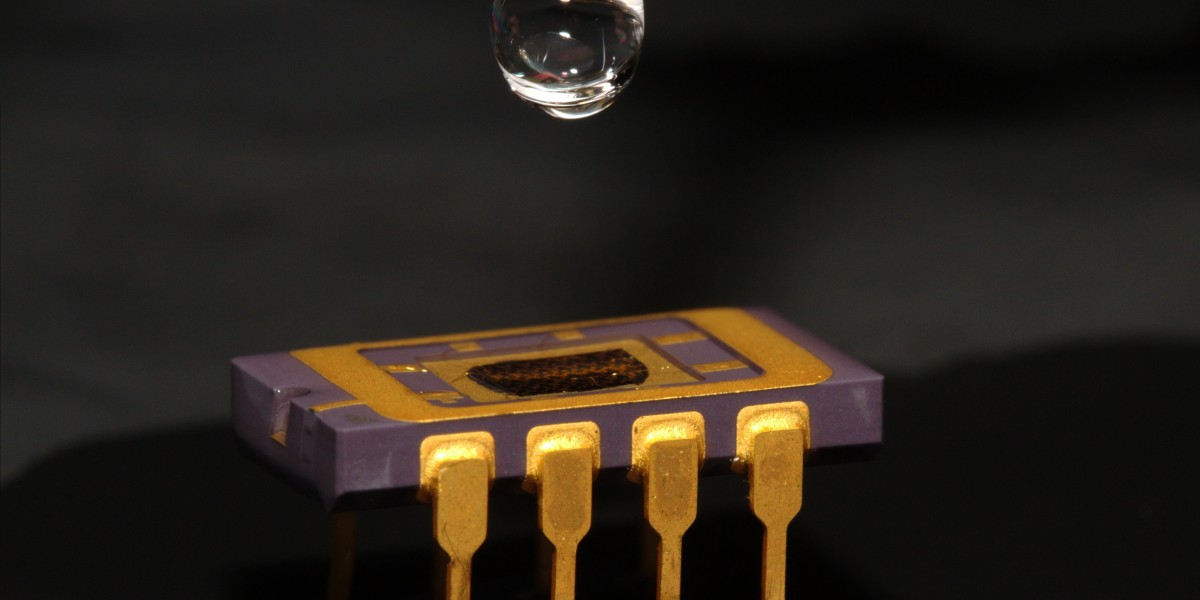

Electronics: Enabling Advanced Functionalities In the electronics industry, zinc oxide is utilized in various applications, ranging from transparent conductive films and varistors to piezoelectric devices and semiconductors. Zinc oxide's unique combination of properties, including high electrical conductivity, transparency, and piezoelectricity, makes it well-suited for use in advanced electronic components and devices.

Transparent conductive films made from zinc oxide nanoparticles are used in displays, touchscreens, solar cells, and optoelectronic devices, where they provide excellent conductivity and optical transparency. Zinc oxide varistors are employed in surge protection devices to suppress transient voltage spikes and protect sensitive electronic equipment from damage.

Conclusion: In conclusion, zinc oxide's diverse applications underscore its importance as a versatile and indispensable compound in various industries. From sunscreens to ceramics, rubber manufacturing to electronics, zinc oxide plays a vital role in enhancing product performance, functionality, and durability. As industries continue to innovate and evolve, the demand for zinc oxide is expected to grow, driven by its unique properties, eco-friendly nature, and wide-ranging applications. By understanding the diverse applications of zinc oxide and leveraging its versatile properties, stakeholders can unlock new opportunities for innovation and sustainable growth across industries.