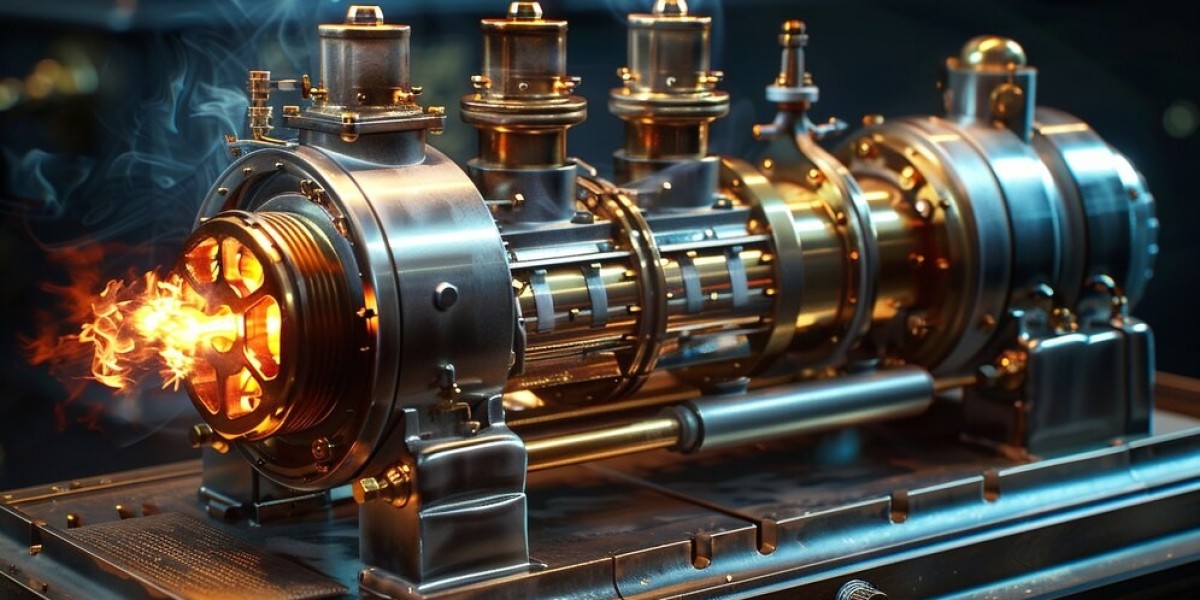

Gas jet compressor market, also known as air or gas ejectors, are mechanical devices used to move gas or air from one location to another by utilizing high-pressure gas as a driving force. These compressors are crucial components in various industries, including oil and gas, chemical processing, HVAC systems, and even aerospace. As industries evolve and demand for energy-efficient solutions grows, the gas jet compressor market is experiencing significant developments. This article explores the latest market trends, key challenges, and the strategies leading companies are adopting to thrive in this competitive landscape.

Growing Demand in Diverse Sectors

The global gas jet compressor market has witnessed steady growth, primarily driven by the rising demand for energy-efficient systems and sustainable technologies. Industries such as oil and gas, chemical processing, power generation, and mining rely heavily on jet compressors for their ability to handle gas flows in high-pressure systems without mechanical moving parts. These compressors offer several benefits, including simplicity, reliability, and low maintenance costs, which are key factors fueling their demand.

In the oil and gas sector, gas jet compressors are increasingly being used for boosting gas flow, pressure regulation, and wellhead gas separation. Their ability to handle corrosive and abrasive gases makes them indispensable in such harsh environments. Additionally, the chemical processing industry benefits from gas jet compressors in the production of various chemicals and industrial gases, where accurate gas flow control is essential.

The growing trend toward reducing carbon emissions and promoting energy efficiency is also influencing the demand for gas jet compressors. They offer an environmentally friendly alternative to traditional mechanical compressors, as they do not require lubrication and have fewer moving parts, reducing the risk of leaks and emissions.

Challenges Facing the Market

Despite the promising growth prospects, the gas jet compressor market faces several challenges that could hinder its expansion. One of the primary obstacles is the high initial cost of installation, which can be a deterrent for small and medium-sized enterprises (SMEs). While gas jet compressors offer low operational and maintenance costs over time, the upfront investment remains a barrier.

Another challenge is the complex design and engineering required to optimize gas jet compressors for specific industrial applications. Each application may have distinct requirements in terms of pressure, flow rate, and gas type, which makes it challenging to design a one-size-fits-all solution. Manufacturers must invest heavily in research and development to create customized solutions that meet these needs.

Furthermore, the lack of skilled labor to operate and maintain these specialized systems presents a skills gap in the market. As the technology advances, finding qualified personnel capable of managing and troubleshooting complex gas jet compressor systems is becoming increasingly difficult.

Winning Strategies for Market Players

To succeed in the competitive gas jet compressor market, companies must adopt several strategies that focus on innovation, cost efficiency, and customer-centric solutions.

Innovation and Technological Advancements: The key to staying ahead in the market is continuous innovation. Manufacturers are focusing on improving the efficiency, durability, and performance of gas jet compressors. Developing smart compressors that integrate with IoT (Internet of Things) technologies for real-time monitoring and predictive maintenance can significantly enhance operational efficiency.

Customization and Application-Specific Solutions: Given the diverse needs of industries, offering customized solutions that cater to specific requirements can give companies a competitive edge. By collaborating closely with clients to understand their unique needs, manufacturers can provide tailored designs that improve compressor performance and reduce operational costs.

Focus on After-Sales Services: Providing excellent after-sales service, including maintenance and training, is another key strategy. Companies that offer comprehensive support to their customers, helping them maintain their gas jet compressors and enhance their lifespan, will foster long-term relationships and increase customer loyalty.

Strategic Partnerships and Collaborations: Partnering with technology providers or other industry leaders can help companies expand their market presence and access new markets. Collaborations allow manufacturers to leverage the expertise of others to innovate and create more efficient solutions, strengthening their position in the global market.

Conclusion

The gas jet compressor market is poised for substantial growth as industries continue to seek energy-efficient and cost-effective solutions. While challenges such as high initial costs and complex designs persist, companies that focus on technological advancements, customized solutions, and strong after-sales services will be well-positioned to capitalize on the growing demand. By embracing innovation and forming strategic partnerships, market players can navigate obstacles and lead the way in this evolving market.