A coolant recycling device is an essential device in modern industries, ensuring sustainable operations, decreased prices, and extended device existence. By reclaiming and reconditioning used coolant, these systems limit waste and decorate performance in business programs. This complete guide explores the benefits, running mechanisms, and the position of crucial components like bag filter out housing in coolant recycling systems. This system is vital for operations where coolant plays a critical role in temperature regulation, lubrication, and debris removal, such as in machining, automotive production, and heavy equipment manufacturing. By ensuring that coolant is clean and reusable, these systems contribute to enhanced equipment performance, lower downtime, and prolonged machinery lifespan.

What is a Coolant Recycling System?

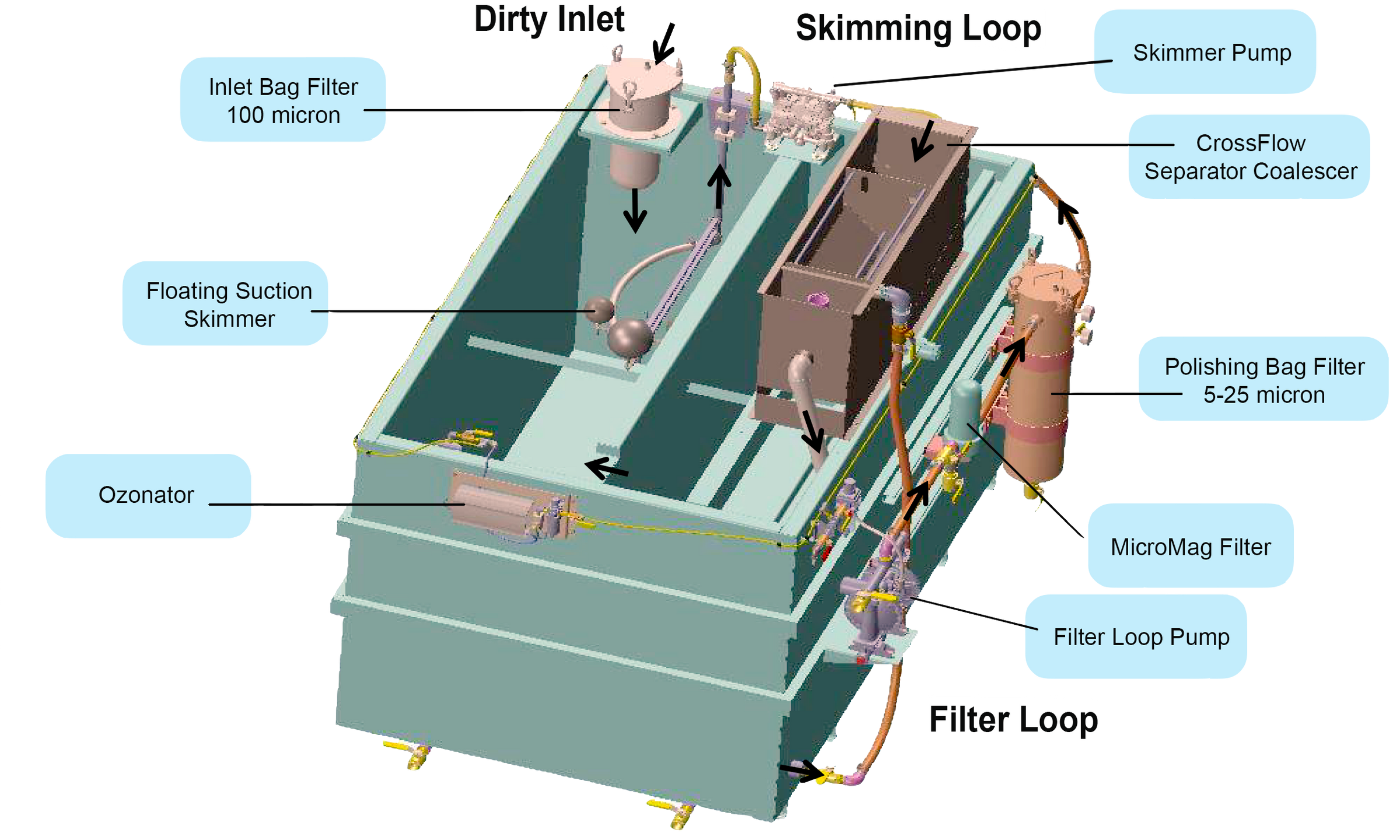

A coolant recycling system is designed to clear out, smooth, and rejuvenate used coolant for reuse. This manner reduces the need for new coolant and minimizes environmental waste. Coolant recycling systems are specifically useful in industries like machining, car, and heavy equipment production, in which coolant is critical for preserving temperature and reducing wear throughout operations.

Central to the recycling technique is the inclusion of filtration mechanisms like bag clear out housing. Bag clear out housing serves as an initial filtration stage, capturing large debris, debris, and contaminants from the used coolant. This guarantees that only exceptional debris flow on to subsequent purification stages, improving the efficiency and lifespan of the recycling machine. By the usage of a coolant recycling machine geared up with bag clear out housing, industries can achieve purifier coolant with decreased operational costs.

How Does a Coolant Recycling System Work?

The coolant recycling process involves numerous tiers: filtration, separation, and reconditioning. Filtration is step one, where impurities like steel chips, oils, and sludge are removed. This is followed by means of separation strategies to remove emulsified oils and water contaminants. Finally, additives are restored to make certain the coolant plays at its most useful level.

Bag clear out housing is necessary to the filtration degree. As coolant flows thru the recycling device, bag clear out housing captures large debris, reducing the weight on finer filters. This enhances the overall filtration performance and ensures that downstream components feature without needless stress. Additionally, bag filter out housing is easy to hold, permitting brief replacement of filters with out disrupting the recycling procedure. The inclusion of this versatile element makes the coolant recycling device more powerful and person-friendly.

The Role of Filtration in Coolant Recycling

Filtration is a cornerstone of coolant recycling, making sure that contaminants are efficaciously removed from the fluid. The first-class of filtration directly influences the performance of the coolant and the gadget it serves. High-high-quality filtration structures put off debris, oils, and other impurities, making sure that recycled coolant meets operational standards.

Bag filter housing enhances this process via appearing as a pre-filtration level. It captures large debris earlier than they attain more sensitive filters, protective these additives from clogging or harm. This dual-degree filtration technique ensures that the recycled coolant is easy and geared up for reuse. Industries that comprise bag filter out housing into their coolant recycling systems benefit from prolonged gadget lifestyles, reduced protection, and improved standard performance. By focusing on filtration, industries can make big strides in sustainability and value performance.

Key Benefits of Using Coolant Recycling Systems

Coolant recycling structures offer a extensive range of benefits, making them necessary in many industrial programs. The number one advantage is value savings, as recycling reduces the need for getting new coolant. Additionally, these systems assist minimize waste, contributing to environmental sustainability. Recycled coolant is also cleaner and extra efficient, enhancing gadget overall performance and lowering wear and tear.

A significant contributor to those advantages is the inclusion of bag filter housing inside the recycling procedure. Bag filter housing reduces operational downtime by using simplifying preservation and improving filtration performance. It also guarantees that contaminants are removed early within the manner, protective downstream additives and lengthening the lifespan of the complete recycling machine. With those advantages, investing in a coolant recycling gadget prepared with bag clear out housing is a clever preference for industries in search of value-effective and sustainable solutions.

Environmental Impact of Coolant Recycling

One of the maximum compelling motives to undertake coolant recycling structures is their fantastic effect at the surroundings. Disposing of used coolant can result in significant environmental risks, as it regularly incorporates heavy metals, oils, and different contaminants. Recycling reduces this waste, ensuring that much less risky fabric ends up in landfills or water structures.

Bag clear out housing plays a critical function in making sure the environmental effectiveness of these systems. By capturing big particles and contaminants early, bag filter out housing prevents them from being released into the surroundings. This pre-filtration level now not handiest protects downstream strategies however also ensures that the coolant meets strict environmental standards earlier than being reused or disposed of. For industries aiming to align with eco-friendly practices, integrating bag clear out housing into their coolant recycling structures is a essential step.

Choosing the Right Coolant Recycling System for Your Needs

Selecting the right coolant recycling machine requires cautious consideration of factors like machine potential, filtration necessities, and maintenance wishes. Industries with excessive coolant usage must choose systems that provide robust filtration skills and smooth preservation. Additionally, the gadget should be well matched with the specific sort of coolant used in the operation.

The inclusion of bag clear out housing is a key feature to search for in a recycling system. Bag filter housing complements the gadget’s filtration performance and decreases upkeep efforts, making it a practical preference for excessive-demand industrial packages. It is also flexible, allowing the use of various filter kinds depending on precise needs. By prioritizing structures with bag filter housing, industries can make sure dependable overall performance and a higher return on investment.

Maintenance Tips for Coolant Recycling Systems

Regular renovation is vital to hold coolant recycling systems walking smoothly. This includes ordinary inspections, clear out replacements, and monitoring fluid fine. Over time, contaminants can building up inside the machine, reducing its performance and effectiveness.

Bag clear out housing simplifies renovation by offering easy get entry to to replaceable filters. By often converting the filters inside the bag filter housing, industries can ensure that their recycling systems perform at height performance. Monitoring the situation of bag clear out housing is equally essential, as a damaged or clogged clear out housing can compromise the entire gadget. Adhering to a strict upkeep time table now not handiest prolongs the existence of the recycling gadget however additionally ensures consistent coolant high-quality.

The Future of Coolant Recycling Technology

Advancements in coolant recycling era are making these systems more green and reachable. Innovations in filtration media, energy-saving designs, and automation are revolutionizing the way industries technique coolant recycling. These enhancements not only enhance system overall performance but also lessen environmental impact and operational expenses.

Bag filter out housing keeps to play a important role in those improvements. Its adaptability to new filtration technologies guarantees that it remains an integral factor of contemporary recycling structures. As industries an increasing number of adopt automatic and AI-driven systems, the simplicity and reliability of bag filter housing will supplement these technologies, imparting a seamless mixture of conventional and modern answers. The destiny of coolant recycling is brilliant, with bag clear out housing set to remain a cornerstone of efficient and sustainable operations.

Why Bag Filter Housing is Essential in Coolant Recycling Systems

Bag clear out housing is extra than only a filtration issue; it's far a cornerstone of efficiency and reliability in coolant recycling systems. By capturing big contaminants on the initial stage, bag filter out housing protects downstream filters and ensures the clean operation of the recycling manner. Its ease of upkeep and flexibility to diverse business needs make it a useful asset.

Integrating bag clear out housing right into a coolant recycling gadget not most effective improves fluid best but additionally reduces operational prices and environmental effect. Industries looking to maximize the benefits of coolant recycling systems have to prioritize the inclusion of bag filter housing in their setups. This easy yet powerful issue is key to accomplishing lengthy-time period sustainability and performance in business packages.

Coolant recycling systems are an important a part of present day business operations, presenting price savings, environmental blessings, and stepped forward gadget performance. Central to these systems is the function of bag filter out housing, which complements filtration performance and simplifies renovation. By making an investment in coolant recycling systems equipped with bag filter housing, industries can attain cleanser coolant, decreased waste, and sustainable operations.