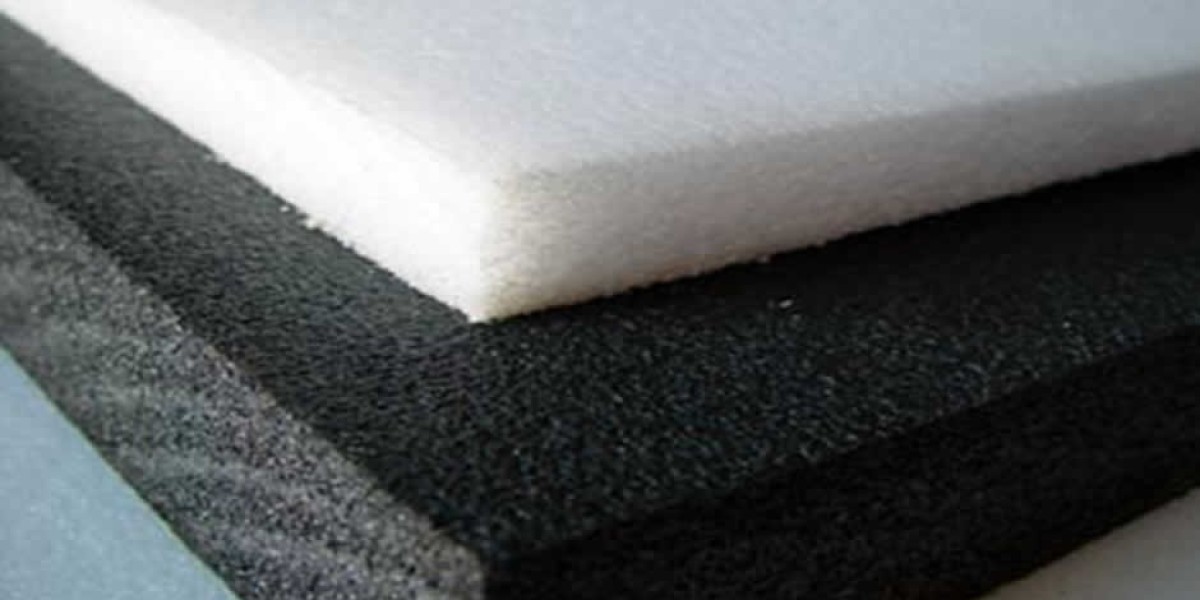

The conductive foam market is experiencing a range of emerging trends as it plays an essential role in the electronics and packaging industries. Conductive foam is used to protect sensitive electronic components from electrostatic discharge (ESD), and with the rapid growth in technology and electronic products, the demand for such materials is expanding. Below are the key emerging trends that are shaping the conductive foam market:

1. Growing Demand for ESD Protection Solutions

With the increased production of electronic devices, especially in the consumer electronics, automotive, and healthcare sectors, the demand for Electrostatic Discharge (ESD) protection solutions is rising. Conductive foam, which is capable of preventing damage caused by static charges, is becoming a go-to solution for manufacturers in these sectors. The rise in smartphones, wearables, electric vehicles, and other smart devices is fueling the need for advanced protection methods, contributing to the growth of the conductive foam market.

2. Technological Advancements in Materials

Innovations in the development of conductive foam materials are a significant trend in the market. Manufacturers are working on improving the conductive properties, durability, and flexibility of foam products to cater to diverse industrial needs. For example, new composite formulations of conductive foam, which combine the traditional foam with other materials such as carbon or silver, are being developed to enhance performance. These innovations are pushing the boundaries of what conductive foam can do, making it an even more critical component in product packaging and transportation of sensitive electronics.

3. Sustainability and Eco-Friendly Solutions

As environmental concerns continue to rise, there is an increasing demand for sustainable and eco-friendly materials across industries. In response, manufacturers are developing biodegradable or recyclable conductive foam options. These products offer the same level of ESD protection but have a significantly lower environmental impact. The push for sustainable products aligns with the global shift toward sustainability in packaging, where businesses are opting for green alternatives to meet consumer and regulatory demands.

4. Expansion in Emerging Markets

Emerging markets, especially in Asia Pacific and Latin America, are witnessing rapid industrialization and growth in electronic manufacturing. As a result, there is a rising demand for conductive foam products. This trend is being driven by an increase in the production of electronics and automotive components, as well as the growth of industries such as medical devices, where ESD protection is crucial. With economies in these regions expanding, the market for conductive foam is seeing significant opportunities for growth.

5. Customization and Versatility

Manufacturers are increasingly offering customized conductive foam products to meet the specific needs of different applications. Customization allows for tailored foam densities, thicknesses, and conductive properties, which are essential for unique applications in packaging, transportation, and storage. For instance, customized foam is used to create protective cushioning for delicate electronic components, ensuring that the foam provides not only ESD protection but also physical safety during transit.

6. Smart Packaging Solutions

With the increasing focus on the Internet of Things (IoT), there has been a rise in the demand for smart packaging solutions that provide real-time monitoring and protection of goods during shipping and storage. Conductive foam, being an excellent material for safeguarding electronic components, is playing an important role in these innovations. For example, foam integrated with radio-frequency identification (RFID) or other tracking technologies can help manufacturers and logistics companies track sensitive components, ensuring that they arrive at their destination safely and without ESD damage.

7. Increase in Consumer Electronics

The growth of the consumer electronics market, particularly smartphones, laptops, wearables, and other mobile devices, is one of the most important drivers for conductive foam demand. These devices contain intricate, sensitive components that need protection during manufacturing and shipping. As the electronics sector grows, the demand for conductive foam, which can shield against electrostatic discharge, will continue to rise.

8. Impact of E-Commerce on Packaging

The rise of e-commerce has led to an increase in online orders, which in turn has impacted the way electronics are packaged and shipped. With many consumers ordering high-value electronics online, the risk of damage during shipping has increased. To protect against electrostatic discharge, conductive foam is increasingly used for packaging electronic products sold through e-commerce platforms. This has driven demand for more efficient and protective packaging solutions.

Conclusion

The conductive foam market is evolving rapidly as it adapts to the changing needs of industries such as electronics, automotive, healthcare, and consumer goods. With the increased importance of ESD protection, technological innovations, sustainability efforts, and emerging market opportunities, the market is poised for further growth. Companies that invest in enhancing their product offerings and tap into emerging trends will be well-positioned to capitalize on the evolving demand for conductive foam in the coming years.