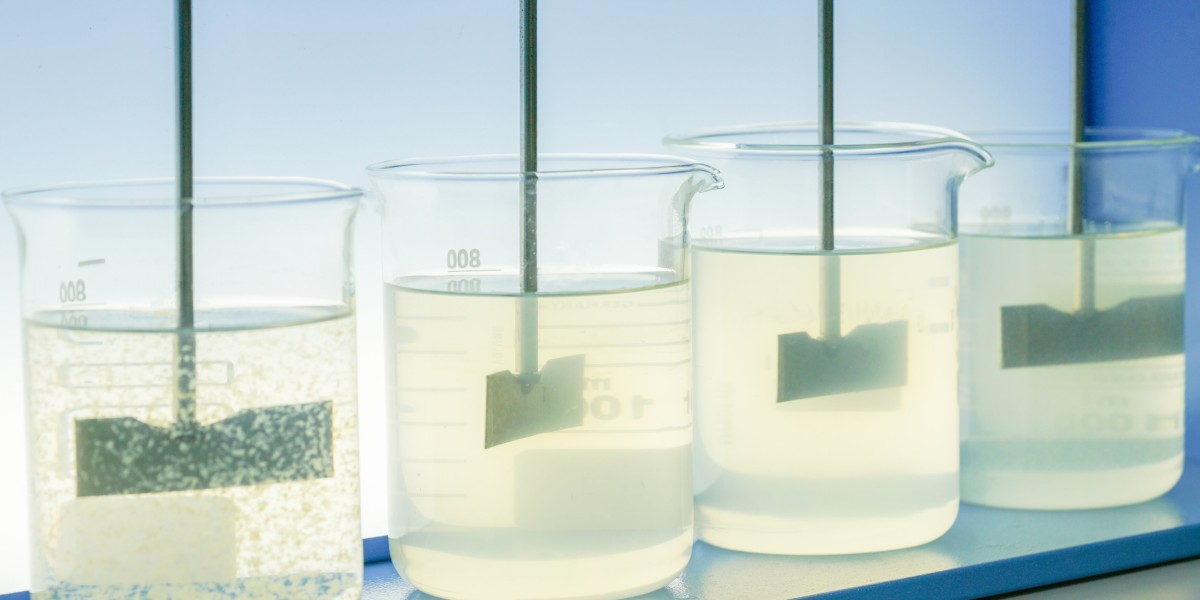

The flocculant and coagulant market plays a critical role in various industries, such as water treatment, mining, paper manufacturing, and others, where controlling sediment and particles is essential. These chemicals, used in the process of coagulation and flocculation, are vital for the efficient removal of impurities from liquids. Despite the growing demand for these chemicals, the market faces several challenges that can impact its development and growth.

Regulatory Constraints

One of the major challenges in the flocculant and coagulant market is the increasing stringency of regulations regarding chemical products. Governments worldwide are implementing more rigorous environmental standards, especially in industries like water treatment, to minimize the ecological impact. These regulations impose limitations on the types of chemicals used in flocculation and coagulation processes, forcing manufacturers to comply with tighter restrictions and invest in research and development to create more environmentally friendly alternatives. For instance, some chemicals traditionally used in flocculation may contain harmful substances that could pose risks to human health or the environment, prompting stricter regulatory frameworks.

Cost of Raw Materials

Flocculants and coagulants are typically derived from raw materials such as synthetic polymers, aluminum salts, and iron-based compounds. The fluctuation in the prices of these raw materials significantly affects the production cost of flocculants and coagulants. For example, the price of raw materials like petroleum and aluminum can be highly volatile due to geopolitical factors, trade barriers, and supply-demand imbalances. These fluctuations may lead to increased production costs, thereby affecting the pricing structure and profitability for companies within the market. Smaller manufacturers, in particular, may struggle to cope with such price variations, which can hinder their market competitiveness.

Environmental and Health Concerns

There are growing concerns surrounding the environmental and health impacts of certain flocculant and coagulant chemicals. Many traditional coagulants contain aluminum and iron salts, which can be hazardous if not properly managed or disposed of. Additionally, some synthetic flocculants can release toxic byproducts when exposed to certain environmental conditions, leading to pollution in water bodies. Public awareness of these risks is rising, prompting consumers and industries to seek more sustainable, non-toxic alternatives. Manufacturers are under increasing pressure to find eco-friendly solutions, yet the development of such alternatives is expensive and time-consuming.

Competition and Market Saturation

The flocculant and coagulant market is highly competitive, with numerous players vying for market share. Larger multinational corporations often dominate the market due to their advanced technological capabilities, extensive distribution networks, and strong financial resources. Smaller companies may struggle to compete with these giants, as they often lack the infrastructure and innovation required to scale their operations. This competitive pressure can lead to market saturation, where the introduction of new products becomes difficult, and growth prospects become limited. For smaller companies, differentiating their products and building brand loyalty are key strategies to survive in this highly competitive market environment.

Technical Limitations in Application

Flocculants and coagulants are used in a range of applications, from water treatment to mining. However, each application has specific requirements and challenges. For example, in water treatment, flocculants must work efficiently in varying water conditions, such as different pH levels and temperatures. This requires manufacturers to develop highly specialized formulations, which can be costly and technologically demanding. Furthermore, achieving optimal performance across a wide range of applications while ensuring cost-effectiveness remains a key challenge. Some applications, such as in mining, require flocculants to work in highly abrasive environments, which demands more advanced and often expensive products.

Supply Chain and Distribution Challenges

The distribution of flocculants and coagulants is another area where challenges arise. These chemicals are often bulky and require careful handling to prevent degradation or contamination. The logistical aspects of transporting these products across long distances can be costly and complex. Moreover, fluctuations in fuel prices, logistical disruptions, and trade policies can all impact the timely delivery of these chemicals. As industries continue to expand globally, ensuring a stable and efficient supply chain becomes a critical challenge for manufacturers and distributors alike.

Conclusion

The flocculant and coagulant market faces several challenges that could hinder its growth potential. Regulatory constraints, rising raw material costs, environmental concerns, competition, technical limitations, and supply chain complexities are all key issues that need to be addressed for continued market success. Despite these hurdles, the market's importance across various industries ensures that innovations and improvements will continue to shape its future. To remain competitive, companies must focus on developing sustainable solutions, improving efficiency, and adapting to evolving market conditions.