Aerospace precision machining plays a huge role in ensuring that aircraft, spacecraft, and other critical technologies meet strict performance and safety standards. Innovation in this field depends heavily on advancements in the tools that are used to craft complex components with high accuracy. These tools not only improve production but also contribute to the growth and reliability of aerospace technology. Let’s take a look at five cutting-edge tools revolutionizing aerospace precision machining.

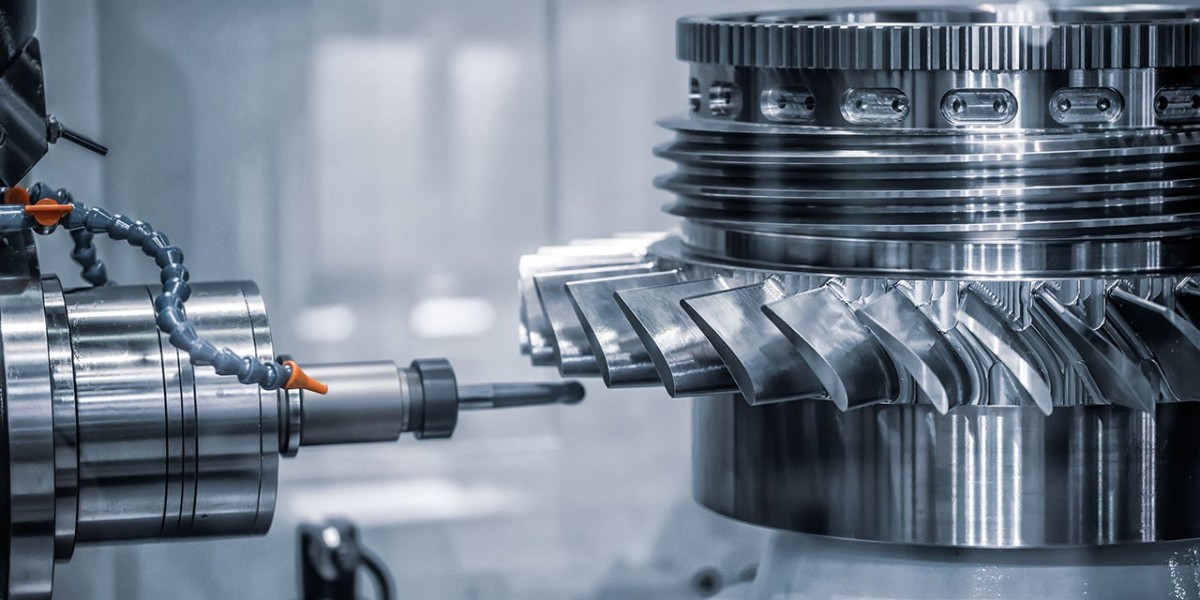

CNC Machining Centers

CNC (Computer Numerical Control) machining centers are at the heart of aerospace precision machining. These machines use computer software to control the movements and operations of machinery, allowing for exceptional precision. By automating processes like drilling, turning, and milling, CNC machines can produce highly complex aerospace parts with flawless accuracy. This technology reduces human error and increases production speed, making it vital to the aerospace industry.

Laser Cutting Systems

Laser cutting technology is another groundbreaking tool in aerospace precision machining. It uses powerful laser beams to cut through hard metals, which is crucial for creating intricate and detailed parts. Laser cutters can make precise cuts without the need for direct contact with materials, making them ideal for delicate aerospace components that demand high accuracy. This method also provides clean, smooth cuts, which means less post-processing work for engineers.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is changing how parts are produced in aerospace. This technology allows designers to create components by building up layers of material, usually metal or plastic, based on 3D digital models. This process is ideal for producing complex shapes that would be hard or impossible to make with traditional machining tools. 3D printing is particularly useful for prototyping, reducing material waste, and creating lightweight parts that are essential in aerospace applications.

EDM Machines

Electrical Discharge Machines (EDM) use controlled electrical sparks to remove material from the surface of metals. This process is especially valuable when working with hard metals that cannot be easily machined with standard cutting tools. The precision offered by EDM machines is unmatched, making them critical for producing detailed parts such as turbine blades and small aerospace components. Their ability to cut with extreme accuracy without applying physical force is a major advantage in aerospace precision machining.

Flexible Magnetic Strips

Lastly, flexible magnetic strips are an exciting tool in the aerospace industry. These strips are often used for material holding or workpiece positioning. Flexible magnetic strips are incredibly versatile, allowing machinists to quickly and easily adjust the position of materials during the machining process. This helps improve speed and accuracy in aerospace machining operations. While simple, their ease of use and precision make them an essential tool for the aerospace industry, allowing companies to stay ahead in production.

Winding Up

The tools listed here are changing the landscape of aerospace precision machining, improving accuracy, speed, and reliability in component production. CNC machines, laser cutting systems, 3D printing, EDM machines, and flexible magnetic strips all contribute to the advanced manufacturing processes we see today. Together, these tools ensure the aerospace industry can produce cutting-edge, high-performance components. With these innovations, aerospace precision machining continues to drive the future of air and space travel.