Caustic soda (sodium hydroxide, NaOH) is a highly valuable chemical used in various industries, including textiles, chlor-alkali, and mining.

The recovery and concentration of caustic soda in these industries are essential for cost-efficiency and environmental sustainability. Here's an overview of caustic soda concentration and recovery in the textile, chlor-alkali, and mining sectors:

1. Textile Industry:

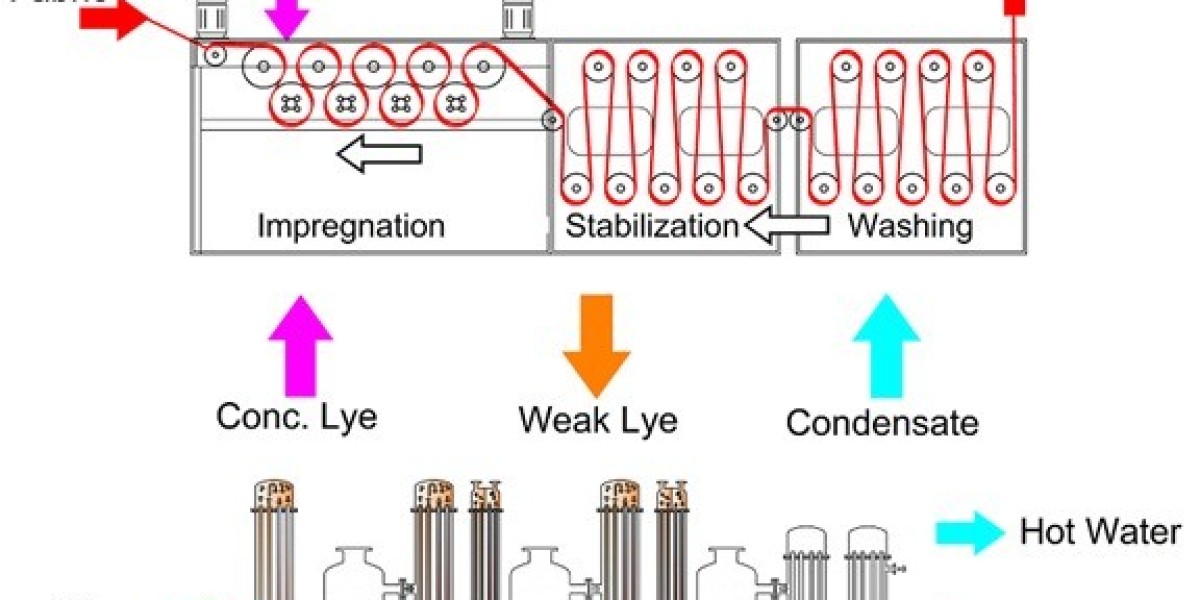

In the textile industry, caustic soda is used for various processes, including mercerization, dyeing, and fabric finishing. To maximize its utility and minimize costs, caustic soda recovery and concentration methods are often employed:

a. Recovery Methods:

Ion-Exchange Resins: Ion-exchange resins can be used to selectively capture and recover caustic soda from wastewater streams.

Electrodialysis: Electrodialysis can be employed to separate and recover caustic soda from wastewater by utilizing ion-selective membranes.

Membrane Filtration: Membrane technologies like reverse osmosis can be used to concentrate caustic soda in wastewater streams.

b. Concentration Methods:

Evaporation: Evaporation is a common method Caustic Soda Concentration Caustic Soda (Naoh) Recovery in the Textile Chlor Alkali Mining Industry for concentrating caustic soda solutions. It involves heating the solution to evaporate the water content, leaving behind concentrated caustic soda.

Crystallization: Caustic soda can be concentrated through crystallization processes, where the solution is cooled to allow caustic soda crystals to form, which can then be separated from the remaining solution.

2. Chlor-Alkali Industry:

The chlor-alkali industry is a major consumer of caustic soda and chlorine. It involves the production of chlorine gas, caustic soda, and hydrogen gas through the electrolysis of brine (sodium chloride solution). Caustic soda recovery and concentration are important for optimizing the efficiency of this process:

a. Recovery Methods:

Membrane Cell Technology: Some modern chlor-alkali plants use membrane cell technology, which allows for the selective separation and recovery of caustic soda, chlorine, and hydrogen gas.

Ion-Exchange and Electrodialysis: Similar to the textile industry, ion-exchange and electrodialysis can be used to recover and purify caustic soda from the brine solution.

b. Concentration Methods:

Evaporation: Evaporation is commonly used to concentrate caustic soda in the chlor-alkali industry, where the concentrated caustic soda can be used in various applications.

3. Mining Industry:

In the mining industry, caustic soda is used for several purposes, including ore processing, alumina extraction, and pH control in water treatment. The recovery and concentration of caustic soda in mining processes are essential for reducing operational costs and minimizing environmental impact:

a. Recovery Methods:

Precipitation: Caustic soda can be recovered through the precipitation of aluminum hydroxide or other compounds, depending on the mining process.

Solvent Extraction: Solvent extraction techniques can be employed to recover caustic soda from mining solutions.

b. Concentration Methods:

Evaporation: Similar to other industries, evaporation is used to concentrate caustic soda solutions in the mining sector.

In all of these industries, the choice of specific methods for caustic soda recovery and concentration depends on factors such as the composition of the waste streams, energy costs, environmental regulations, and overall process efficiency. Implementing effective recovery and concentration processes can lead to cost savings, reduced waste generation, and a more sustainable operation.