In the intricate dance of craftsmanship and technology, laser engraver machines are the artists of the modern era, transforming plain surfaces into works of art. These machines are not just tools but the very extension of the creators' vision, etching with light to produce precise, detailed, and enduring designs. This article will explore the world of laser engravers, addressing common questions and concerns while highlighting the machine's versatility and impact.

The Brilliance of Laser Engraving:

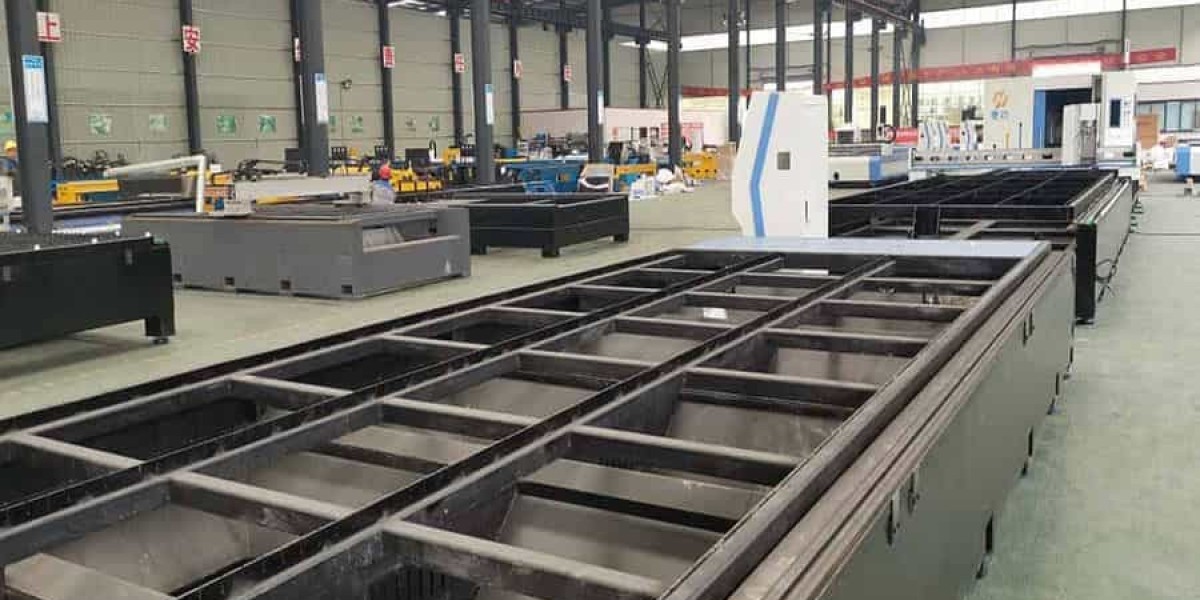

Laser engravers employ the focused power of a laser to vaporize material surfaces, creating engravings that range from simple line art to complex photorealistic images. They are used across numerous industries, from creating personalized jewelry to fabricating high-precision industrial components.

Addressing User Concerns:

1. Material Flexibility: A frequent question is the variety of materials suitable for a laser engraver. While different lasers have different specialties, generally, laser engravers can work with a multitude of materials, including wood, acrylic, glass, leather, and metals. Selecting the right type of laser for your material is crucial for achieving optimal results.

2. Design Intricacy: Users often wonder about the level of detail that can be achieved. Modern laser engravers are incredibly precise, capable of reproducing even the most intricate designs that manual methods cannot match. This precision opens up new possibilities for customizations and complex patterns.

3. Production Efficiency: Efficiency is another key benefit. Laser engravers operate at remarkable speeds and can replicate the same design flawlessly multiple times, greatly enhancing production capability. This makes them ideal for both one-off projects and mass production.

4. Machine Maintenance: Concerns about maintenance are common. The good news is that laser engravers typically require less upkeep than traditional engraving tools. Periodic cleaning of lenses and mirrors, along with proper calibration, can ensure the longevity of the machine.

5. Safety Protocols: Safety is a priority with any industrial machine. Laser engravers are built with numerous safety features, but it is imperative to follow operational protocols. Proper training, protective gear, and adherence to safety standards are non-negotiable to ensure a safe working environment.

6. Cost-Effectiveness: While the initial investment in a laser engraver may seem significant, the machine's ability to increase production speed, reduce waste, and create high-value, personalized items can quickly offset the cost. It's an investment in quality and capability that often pays dividends.

7. Learning Curve: Lastly, potential users are curious about the difficulty of learning to use a laser engraver. Thanks to intuitive software and user-friendly interfaces, the learning curve is shorter than one might expect. With basic training, users can begin creating detailed engravings in no time.

In essence, laser engraver machines represent a fusion of art and precision, enabling businesses and hobbyists alike to unleash their creativity. Whether it's for personalizing gifts, enhancing product offerings, or creating intricate industrial designs, laser engravers offer a level of sophistication and finesse that is truly unmatched.