The highly anticipated Hydrogen Cyanide Production Cost Analysis Report is here, offering a thorough assessment of the production process, key market drivers, and recent developments shaping this pivotal market. The report provides a holistic overview of the production processes and their associated costs, enabling businesses and stakeholders to comprehend this complex industry with unparalleled precision.

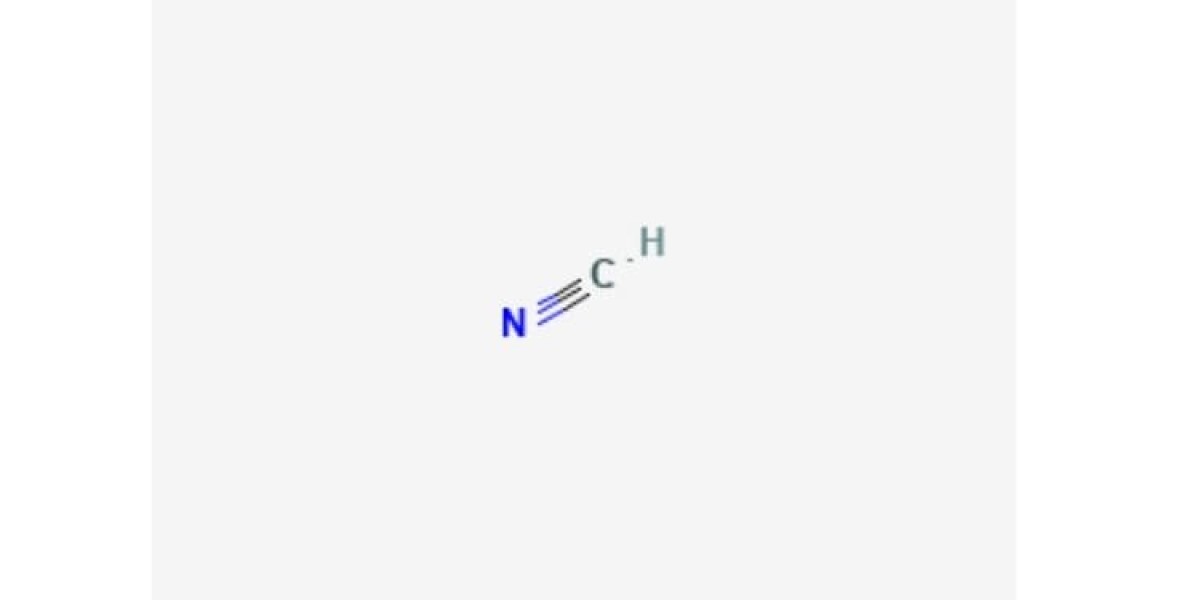

Definition of Hydrogen Cyanide

Hydrogen cyanide (HCN) is a colorless, extremely toxic, and flammable chemical compound. It's also known by its older name, prussic acid. Widely used as a precursor for a variety of chemical compounds, including pharmaceuticals, dyes, synthetic fibers, plastics, and pesticides, hydrogen cyanide serves as a cornerstone of several critical manufacturing processes. Despite its toxicity, its applications are vast due to its versatility in chemical synthesis. However, given its dangerous nature, production requires adherence to strict safety and environmental protocols.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/hydrogen-cyanide/request-sample

Procurement Resource Assessment of Hydrogen Cyanide Production Process

Understanding procurement and the production process of hydrogen cyanide is essential for effectively managing production costs. The Procurement Resource Assessment details the key production methodologies, including the Andrussow, BMA (Degussa), and Shawinigan processes. Each of these processes is evaluated for its economic efficiency, resource consumption, yield rates, and environmental impact.

Andrussow Process: This method relies on the reaction between ammonia, methane, and air over a platinum catalyst. It is one of the most widely used methods due to its relatively high yield and efficiency.

BMA Process: The Degussa (BMA) process involves the catalytic decomposition of gaseous ammonia and methane in the absence of air. This technique is energy-intensive but produces hydrogen cyanide with high purity.

Shawinigan Process: In this process, methane and ammonia are passed through an electric arc, leading to decomposition and formation of hydrogen cyanide. Though it requires high energy input, it offers quick production rates.

The report provides cost analyses for each process, considering variables such as raw material prices, energy consumption, and catalyst use, alongside the implications of environmental regulations.

Market Drivers of Hydrogen Cyanide

Growth of the Chemical Industry: The burgeoning chemical sector continues to drive demand for hydrogen cyanide, as it serves as an essential intermediate for producing acrylonitrile, methyl methacrylate, and other chemicals.

Automotive Industry Expansion: As hydrogen cyanide is a precursor for the production of nylon-66, a vital material in automotive parts, the expanding automotive industry is fueling demand.

Increasing Agricultural Demand: Pesticides and fumigants made from hydrogen cyanide are pivotal in modern agriculture. Therefore, rising agricultural activities contribute significantly to market growth.

Pharmaceutical Applications: The pharmaceutical industry's reliance on intermediates derived from hydrogen cyanide, such as sodium cyanide, drives its demand further.

Latest News For Hydrogen Cyanide Market

The hydrogen cyanide market is evolving rapidly with several developments:

Innovations in Production Technologies: New, energy-efficient catalytic processes are under development, aiming to reduce environmental impact and production costs.

Regulatory Changes: Governments are implementing stricter regulations around the handling and production of hazardous chemicals, affecting market dynamics and compliance costs.

Strategic Partnerships: Major players are entering strategic partnerships and mergers to consolidate their position and expand production capacities.

Sustainable Practices: The trend toward sustainable practices is pushing companies to adopt greener production methods, including recycling by-products.

Product Details of Hydrogen Cyanide

Hydrogen cyanide typically presents itself as a solution, stabilized for safe transport and application. In industrial settings, it’s often stored in pressurized containers. The concentration and quality of the hydrogen cyanide produced vary according to the production process employed and the intended application. The product is available in different grades, each suitable for specific industries, including agrochemicals, mining, and textiles.

Key Questions Answered in This Report

What are the primary production processes used for hydrogen cyanide, and how do they compare in terms of cost and yield?

Which market drivers are propelling the demand for hydrogen cyanide?

What are the key challenges facing hydrogen cyanide producers in terms of regulations and safety standards?

How are recent technological advancements influencing production methods and costs?

What strategic opportunities exist for businesses aiming to enter or expand in the hydrogen cyanide market?

How are emerging trends, such as sustainability and partnerships, shaping market dynamics?

Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business?

This report is tailored to provide businesses with the insights needed to make strategic decisions confidently. It includes a comprehensive analysis of production methods, market dynamics, and cost structures, ensuring companies can optimize their operations and achieve a competitive edge. Whether you're a current market player or considering entering the field, this report offers actionable data to support strategic planning, investment analysis, and competitive positioning.

Conclusion

The Hydrogen Cyanide Production Cost Analysis Report is a must-have resource for businesses seeking to understand the intricate landscape of this market. By providing a granular analysis of production processes, market drivers, and recent developments, the report empowers stakeholders to navigate challenges and harness opportunities effectively. In an industry where regulatory compliance, environmental impact, and production costs are ever-changing, having a comprehensive view of the market is crucial for sustainable growth.