The manufacturing sector has always been at the forefront of adopting new technologies to enhance productivity and efficiency. Today, artificial intelligence (AI) is playing a transformative role in manufacturing, driving significant changes across the industry. The AI in manufacturing market is experiencing rapid growth, driven by advancements in machine learning, robotics, and data analytics.

Market Overview

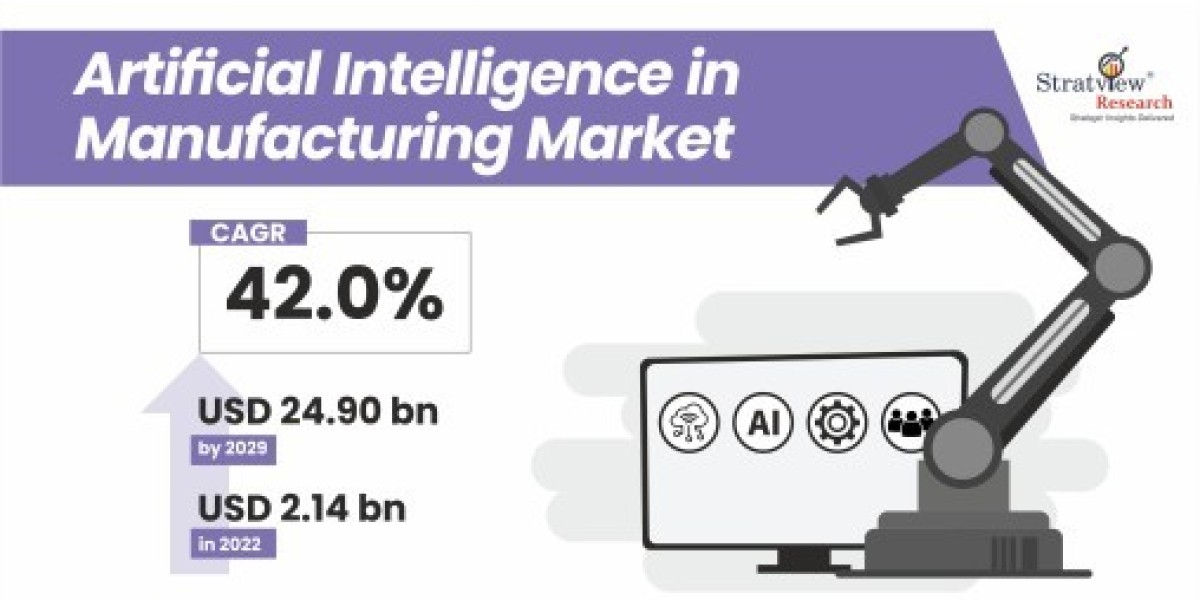

"The global artificial intelligence in manufacturing market is expected to grow from USD 2.14 billion in 2022 to USD 24.90 billion by 2029 at a CAGR of 42.0% during the forecast period".

Key Drivers

Several factors are driving the adoption of AI in manufacturing:

Automation and Robotics: AI-powered robots and automated systems are revolutionizing production lines, reducing the need for human intervention and minimizing errors. These systems are capable of performing complex tasks with high precision and speed, leading to increased productivity.

Predictive Maintenance: AI algorithms analyze data from machinery and equipment to predict potential failures and maintenance needs. This proactive approach reduces downtime and extends the lifespan of machinery, resulting in significant cost savings.

Quality Control: AI-driven quality control systems use computer vision and machine learning to detect defects in products in real-time. This ensures that only high-quality products reach the market, reducing waste and improving customer satisfaction.

Supply Chain Optimization: AI enhances supply chain management by predicting demand, optimizing inventory levels, and improving logistics. This leads to more efficient operations and reduced costs.

Enhanced Design and Prototyping: AI aids in the design process by generating innovative product designs and optimizing prototypes. This accelerates the development cycle and brings products to market faster.

Challenges

Despite the numerous benefits, the adoption of AI in manufacturing also presents challenges:

High Initial Investment: Implementing AI technologies requires significant upfront investment in hardware, software, and training.

Integration with Existing Systems: Integrating AI solutions with legacy systems can be complex and time-consuming.

Data Security and Privacy: The use of AI involves handling large volumes of data, raising concerns about data security and privacy.

Skill Gap: There is a growing need for skilled professionals who can develop, implement, and manage AI systems.

Future Outlook

The future of AI in manufacturing looks promising, with continuous advancements in technology expected to drive further growth. The integration of AI with other emerging technologies, such as the Internet of Things (IoT) and 5G, will create new opportunities for innovation and efficiency.

Manufacturers who embrace AI early will gain a competitive edge, improving their operational efficiency, product quality, and customer satisfaction. As AI technology evolves, its applications in manufacturing will become even more diverse, transforming the industry in ways we can only begin to imagine.

Conclusion

The AI in manufacturing market is on the brink of a revolution, with significant potential to enhance efficiency, reduce costs, and improve product quality. While there are challenges to overcome, the benefits far outweigh the risks. As the technology continues to advance, AI will become an integral part of the manufacturing landscape, driving innovation and growth in the industry.

To read in detail about the market dynamics, Register Here: https://www.stratviewresearch.com/Request-Sample/3275/artificial-intelligence-in-manufacturing-market.html#form