Among these innovations, brush drilling and filling machine stand out as pivotal in revolutionizing production processes. These machines are not just enhancing efficiency but are also setting new benchmarks in product quality and customization.

Understanding Brush Drilling and Filling Machines

What Are Brush Drilling and Filling Machines?

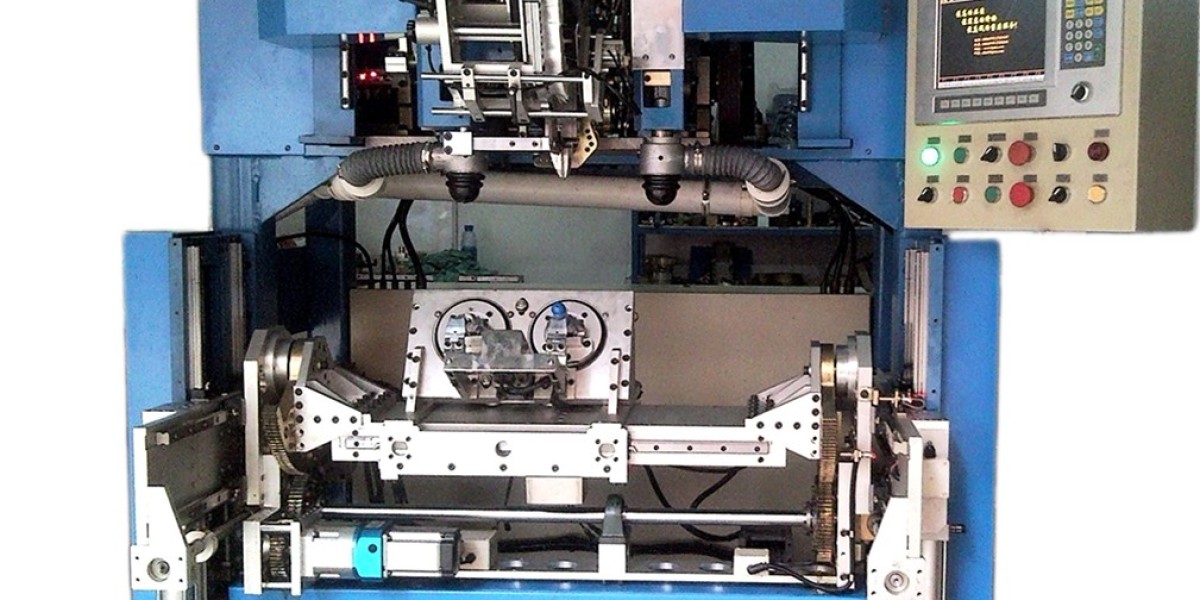

Brush drilling and filling machines are specialized devices designed to automate the processes of drilling holes into brush handles and filling these handles with bristles. This equipment is crucial for the production of various home goods, including cleaning brushes, paint brushes, and personal care brushes.

Drilling involves creating precise holes in brush handles, which is essential for secure bristle insertion. Filling refers to the insertion of bristles into these pre-drilled holes, ensuring they are evenly distributed and firmly attached.

Key Features of Modern Machines

Automation: Modern brush drilling and filling machines feature advanced automation systems that handle repetitive tasks with high precision.

Customization: These machines offer flexible settings to accommodate different brush designs and sizes.

Efficiency: High-speed operation and minimal manual intervention lead to faster production cycles.

Impact on the Home Goods Industry

Enhanced Production Efficiency

One of the most significant benefits of brush drilling and filling machines is the dramatic increase in production efficiency. Traditional methods of drilling and filling brushes were labor-intensive and time-consuming. In contrast, automated machines perform these tasks swiftly and accurately, significantly reducing production times. This efficiency allows manufacturers to meet higher demand levels and respond quickly to market trends.

Improved Product Quality

Consistency in product quality is another major advantage offered by these machines. Automated drilling and filling processes ensure that each brush is made to the exact specifications required, minimizing defects and variations. This precision translates into higher-quality products that meet rigorous standards and enhance customer satisfaction.

Cost Reduction

The automation of drilling and filling processes leads to substantial cost savings. By reducing the need for manual labor and minimizing errors, manufacturers can lower operational costs. Additionally, the efficiency of these machines helps in reducing waste, as they are designed to optimize material usage and minimize defects.

Technological Innovations in Brush Drilling and Filling Machines

Advanced Automation

The latest brush drilling and filling machines are equipped with sophisticated automation technologies. These machines utilize robotic arms and intelligent control systems to perform precise drilling and filling operations. Automation reduces the need for manual intervention, ensuring faster and more accurate production.

Integration with Smart Technologies

Smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are increasingly being integrated into brush drilling and filling machines. These technologies enable real-time monitoring, data analysis, and predictive maintenance. Manufacturers can track machine performance, identify potential issues before they arise, and optimize production processes based on data insights.

Customization and Versatility

Customization capabilities have been significantly enhanced with modern machines. Manufacturers can easily adjust settings to accommodate different brush designs and materials. This versatility is crucial for meeting diverse consumer needs and adapting to evolving market trends.

Enhanced Safety Features

Safety is a critical concern in manufacturing, and modern brush drilling and filling machines come with advanced safety features. These include automated safety guards, emergency stop functions, and real-time hazard detection systems, ensuring a safer working environment and reducing the risk of accidents.

Future Trends and Prospects

The future of brush drilling and filling machines looks promising, with several emerging trends likely to shape the industry. Continued advancements in automation and smart technologies will further enhance machine capabilities and efficiency. Additionally, there is a growing emphasis on sustainable manufacturing practices, which will drive the development of machines that support eco-friendly production.

Customization and versatility will remain key focus areas, with manufacturers seeking machines that can handle a wide range of brush types and designs. As consumer preferences evolve, the ability to produce innovative and personalized products will be crucial for maintaining a competitive edge.

Conclusion

brush drilling and filling machine are transforming the home goods industry by enhancing production efficiency, improving product quality, and reducing costs. The integration of advanced automation, smart technologies, and customization capabilities is setting new standards in brush manufacturing. As technology continues to advance, these machines will play an increasingly vital role in shaping the future of the industry, driving innovation, and meeting evolving consumer demands.

Follow Us More Social Media links:-

Click Here:- https://borghiindia.com

Follow Us On Facebook:- https://www.facebook.com/people/Borghi-India/100075660567841/

Follow Us On Linkedin:- https://www.linkedin.com/in/borghi-india-516b37222/

Follow Us On Instagram:- https://www.instagram.com/borghi.india/

Add:- B-315/316, Damji Shamji Corporate Square, Kanara Business Centre Compound, Laxmi Nagar,Ghatkopar Andheri Link Road, Ghatkopar (East), Mumbai 400 075

Phone: +91 22 62231691 || +9619140918

Email: info@borghiindia.com