Project Overview

Purpose and Objectives

The primary goal of the Sodium Percarbonate Manufacturing Plant Project is to create a facility capable of producing high-quality sodium percarbonate to meet market demand. Key objectives include:

- Ensuring Reliable Supply: Establishing a stable production process to consistently meet customer needs.

- Maintaining Product Quality: Adhering to stringent quality standards to ensure the efficacy and safety of the final product.

- Promoting Environmental Sustainability: Leveraging sodium percarbonate's eco-friendly attributes to support sustainable product offerings.

Get a Free Sample Report with Table of Contents @

Market Analysis

A thorough market analysis is essential to understand the viability and potential success of the manufacturing plant. This analysis includes:

- Demand Assessment: Evaluating current and projected demand for sodium percarbonate in various applications such as cleaning agents, laundry products, and industrial uses.

- Competitive Landscape: Identifying existing manufacturers and their market share to strategize effectively and position the plant competitively.

- Regulatory Environment: Understanding regulatory requirements and standards for sodium percarbonate production.

Project Planning

Site Selection

Selecting an optimal location for the manufacturing plant is crucial for its success. Considerations include:

- Proximity to Raw Materials: Ensuring access to suppliers of key raw materials such as sodium carbonate and hydrogen peroxide.

- Infrastructure: Availability of necessary infrastructure, including transportation, utilities, and waste management systems.

- Regulatory Compliance: Ensuring the site adheres to local zoning laws, environmental regulations, and safety standards.

Regulatory Compliance

Compliance with industry regulations is critical for the successful operation of the plant. Key regulatory considerations include:

- Licensing: Obtaining necessary licenses and permits from relevant authorities to operate the manufacturing facility.

- Good Manufacturing Practices (GMP): Adhering to GMP guidelines to ensure the quality and safety of sodium percarbonate production.

- Environmental Regulations: Complying with regulations related to waste management, emissions, and overall environmental impact.

Technology and Equipment

The production of sodium percarbonate requires specialized technology and equipment. Key components include:

- Reactors: For the chemical reaction between sodium carbonate and hydrogen peroxide to produce sodium percarbonate.

- Drying Equipment: To dry the sodium percarbonate to the desired powder consistency.

- Packaging Machinery: For the efficient and secure packaging of the final product.

Manufacturing Process

Raw Materials

The primary raw materials for producing sodium percarbonate are:

- Sodium Carbonate (Soda Ash): A key ingredient in the synthesis process.

- Hydrogen Peroxide: The other essential reactant needed to produce sodium percarbonate.

Ensuring the quality and availability of these raw materials is vital for maintaining consistent production.

Production Steps

Preparation: The raw materials, sodium carbonate and hydrogen peroxide, are prepared and measured according to precise formulations.

Reaction: The sodium carbonate and hydrogen peroxide are mixed in a reactor under controlled conditions to initiate the chemical reaction that produces sodium percarbonate.

Crystallization: The reaction mixture is allowed to cool and crystallize, forming sodium percarbonate crystals.

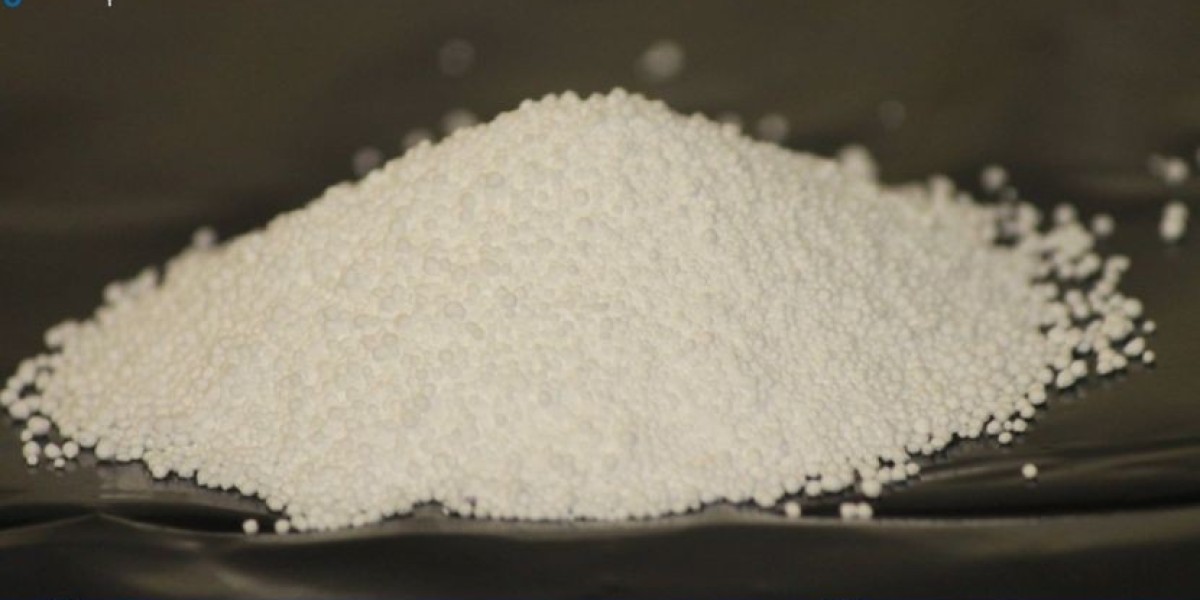

Drying: The crystallized sodium percarbonate is dried using drying equipment to achieve the desired powder form.

Packaging: The final product is packaged in appropriate containers to ensure stability and prevent contamination during storage and transportation.

Quality Control

Maintaining high-quality standards is essential in sodium percarbonate manufacturing. The quality control process includes:

- Raw Material Testing: Verifying the quality and suitability of raw materials before use in production.

- In-Process Monitoring: Continuously monitoring production parameters to ensure consistency and adherence to quality standards.

- Final Product Testing: Conducting thorough testing of the finished product to confirm its purity, efficacy, and safety.

Environmental and Safety Considerations

Environmental Impact

The production of sodium percarbonate can have environmental implications, including waste generation and emissions. Addressing these impacts involves:

- Waste Management: Implementing systems for the treatment and disposal of chemical waste generated during production.

- Emission Control: Using technologies and practices to minimize emissions and comply with environmental regulations.

Safety Measures

Worker safety is paramount in the manufacturing plant. Key safety measures include:

- Personal Protective Equipment (PPE): Providing appropriate PPE to all workers involved in handling chemicals.

- Training: Regularly training employees on safety protocols, handling procedures, and emergency response.

- Safety Equipment: Installing safety features such as eyewash stations, emergency showers, and fire extinguishers.

Financial Analysis

Cost Estimation

Accurate cost estimation is crucial for financial planning and includes:

- Capital Investment: Costs related to plant construction, equipment purchase, and installation.

- Operational Costs: Ongoing expenses such as raw materials, labor, utilities, and maintenance.

- Marketing and Distribution: Costs associated with promoting and distributing sodium percarbonate.

Profitability Analysis

Conducting a profitability analysis helps assess the project's financial viability by:

- Revenue Forecasting: Estimating potential revenue based on market demand and pricing strategies.

- Return on Investment (ROI): Calculating the ROI to evaluate the financial benefits and sustainability of the project.

FAQ

What is sodium percarbonate used for?

Sodium percarbonate is used primarily as a bleaching agent and cleaning product. It releases oxygen when dissolved in water, making it effective in removing stains and disinfecting surfaces. It's commonly found in laundry detergents, cleaning products, and as an eco-friendly alternative to traditional bleach.

What are the main challenges in manufacturing sodium percarbonate?

Key challenges include managing the reaction between sodium carbonate and hydrogen peroxide safely, ensuring high product purity, adhering to environmental regulations, and maintaining consistent quality in production.

How long does it take to set up a sodium percarbonate manufacturing plant?

Setting up a sodium percarbonate manufacturing plant typically takes between 12 to 18 months, depending on factors such as site preparation, equipment installation, and regulatory approvals.

What safety measures are required for handling sodium percarbonate?

Safety measures include using personal protective equipment (PPE) such as gloves and goggles, providing employee training on safe handling and emergency procedures, and implementing strict safety protocols in the production area.

How can I ensure environmental compliance in sodium percarbonate production?

Ensuring environmental compliance involves implementing effective waste management systems, controlling emissions, and adhering to local environmental regulations. Regular environmental audits and impact assessments are also important for maintaining compliance.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/