The linear alpha olefins market is experiencing significant growth, largely driven by the increasing demand for polyethylene production. Linear alpha olefins, such as 1-butene, 1-hexene, and 1-octene, play a critical role as comonomers in the production of polyethylene, particularly high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). These materials are essential for various industries, including packaging, automotive, construction, and consumer goods, making them highly sought after globally.

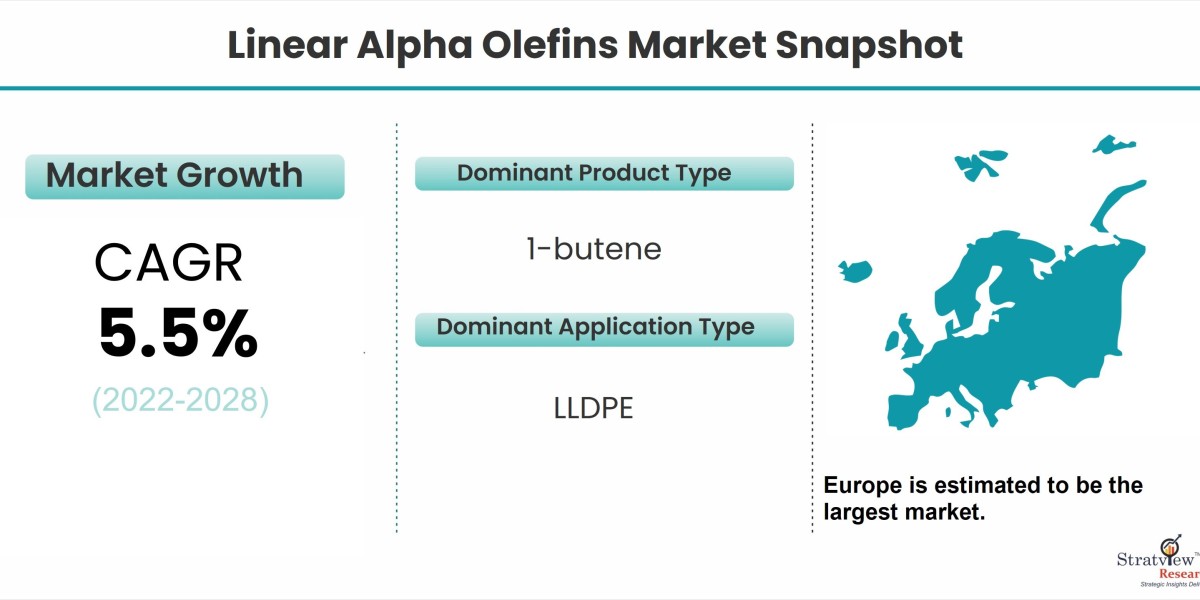

According to Stratview Research, the Linear Alpha Olefins Market is likely to witness an impressive CAGR of 5.5% during the forecast period.

Role of Linear Alpha Olefins in Polyethylene Production

Polyethylene is the most widely used plastic globally, with applications ranging from packaging materials, such as films, bottles, and containers, to pipes, automotive parts, and household goods. The inclusion of linear alpha olefins as comonomers in the polyethylene production process enhances the material's properties, such as tensile strength, flexibility, impact resistance, and clarity. For instance, 1-hexene and 1-octene are commonly used in LLDPE production to improve its flexibility and impact strength, making it ideal for stretch films and packaging applications.

Key Drivers of Rising Demand

- Growing Packaging Industry:

- The packaging industry is the largest consumer of polyethylene, and its rapid growth is a significant driver of the increasing demand for linear alpha olefins. With the rise of e-commerce, food and beverage packaging, and sustainable packaging solutions, there is a surge in demand for high-performance polyethylene products. Flexible packaging, in particular, benefits from LLDPE's strength and lightweight properties, which are enhanced by the use of linear alpha olefins.

- Automotive and Construction Applications:

- In the automotive and construction sectors, HDPE is widely used for manufacturing fuel tanks, piping systems, and geomembranes due to its high durability and chemical resistance. The use of linear alpha olefins in HDPE production improves the material's performance under extreme conditions, making it a preferred choice for these industries. As automotive manufacturers increasingly seek lightweight and fuel-efficient materials, the demand for LAO-based polyethylene continues to grow.

- Advancements in Polyethylene Manufacturing:

- Technological advancements in polyethylene production processes, such as metallocene catalysis, have enabled the development of tailored polyethylene grades with superior properties. Linear alpha olefins are critical in these advanced production processes, contributing to the creation of specialty polyethylenes that cater to specific applications. These innovations drive the need for high-purity linear alpha olefins to produce polyethylene with desired characteristics.

- Sustainability and Recycling Initiatives:

- The global focus on sustainability and the circular economy is also impacting the demand for polyethylene and, consequently, linear alpha olefins. Polyethylene’s recyclability makes it an attractive choice for sustainable packaging solutions. As companies and governments emphasize recycling and reducing plastic waste, the demand for high-quality polyethylene products, made with linear alpha olefins, is set to rise.

Conclusion

The rising demand for linear alpha olefins in polyethylene production is a result of growing end-use applications in packaging, automotive, construction, and other sectors. As the market continues to evolve with technological advancements and a greater emphasis on sustainability, the role of linear alpha olefins in producing high-performance polyethylene will become even more significant. Manufacturers and suppliers in the linear alpha olefins market are well-positioned to benefit from these trends by focusing on innovation and expanding their production capacities.