Polycarbonate (PC) hollow sheets have become a popular choice in modern construction and design due to their exceptional properties like durability, lightweight structure, and versatility. These hollow-core sheets provide a perfect balance between strength and flexibility, making them an ideal solution for a variety of indoor and outdoor applications. From skylights and roofing systems to greenhouses and partitions, PC hollow sheets offer a wide range of benefits that make them a preferred material in several industries.

In this article, we’ll explore the features, benefits, and applications of Polycarbonate Hollow Sheet, along with a detailed FAQ section to answer common questions.

What Are PC Hollow Sheets?

PC hollow sheets are made from polycarbonate resin, a thermoplastic material known for its high impact resistance, transparency, and insulation properties. The term “hollow” refers to the sheet's internal structure, which consists of two or more layers separated by air-filled channels. This unique design reduces the weight of the sheet while maintaining its structural integrity, making it a lightweight yet sturdy material.

The combination of strength, insulation, and transparency makes PC hollow sheets an ideal solution for projects that require natural lighting, thermal regulation, and durability.

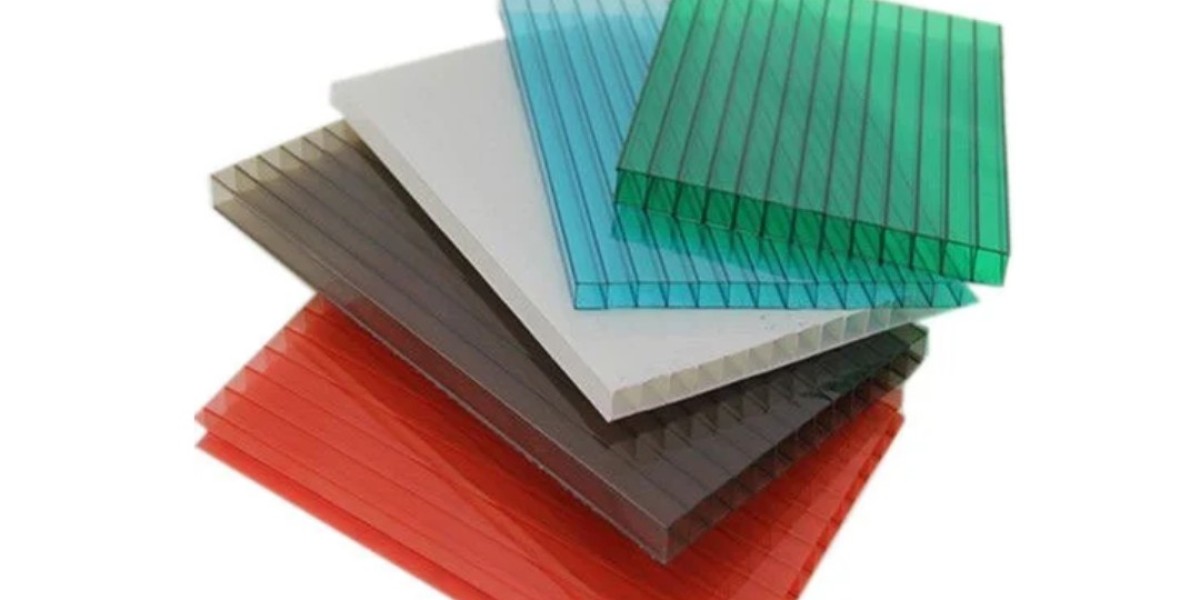

Types of PC Hollow Sheets

There are various types of PC hollow sheets depending on their application and design, such as:

- Twin-Wall Sheets: These are the most common type of hollow sheets with two layers of polycarbonate separated by air pockets.

- Triple-Wall Sheets: These offer even better thermal insulation due to the additional layer of polycarbonate.

- Multi-Wall Sheets: With more than three layers, these provide excellent insulation for large buildings.

- Custom-Shaped Hollow Sheets: Some PC hollow sheets are custom-made for specific architectural or industrial purposes.

Key Features of PC Hollow Sheets

1. Lightweight Yet Strong

PC hollow sheets are up to 80% lighter than glass but offer similar strength. The hollow core structure reduces weight while still providing excellent impact resistance. This makes transportation and installation easier and less costly.

2. High Impact Resistance

Polycarbonate is known for its toughness. PC hollow sheets are nearly unbreakable and can withstand harsh conditions like hail, high winds, or physical impacts. This makes them ideal for outdoor applications where safety and durability are a concern.

3. Transparency

While PC hollow sheets are not as transparent as glass, they still offer high levels of light transmission. Depending on the thickness, these sheets can allow 40% to 80% of natural light to pass through, making them perfect for applications like skylights and greenhouses.

4. Thermal Insulation

The air pockets between the layers of PC hollow sheets act as insulators, reducing heat transfer. This helps to regulate indoor temperatures, making them an energy-efficient solution for buildings and structures.

5. UV Protection

PC hollow sheets are often coated with a UV-resistant layer that protects them from the harmful effects of sunlight. This helps to prevent yellowing, cracking, and loss of transparency over time, extending the lifespan of the sheets.

6. Flexibility

PC hollow sheets can be bent or curved without losing their strength, making them suitable for various architectural designs, including curved roofs or walls.

7. Fire Resistance

Polycarbonate is a fire-resistant material, which adds a layer of safety to any structure that uses PC hollow sheets. They are less likely to catch fire compared to other plastic materials.

Common Applications of PC Hollow Sheets

Thanks to their unique properties, PC hollow sheets are used in a variety of applications, including:

1. Greenhouses

PC hollow sheets are ideal for greenhouses because they offer excellent light transmission and thermal insulation. They provide the necessary sunlight for plants to grow while keeping the interior temperature stable.

2. Skylights and Roofing

These sheets are widely used for roofing and skylight applications, allowing natural light to enter while keeping out the elements. Their lightweight nature makes them easier to install on larger surfaces compared to glass.

3. Canopies and Awnings

PC hollow sheets provide shade and protection from the weather while allowing filtered light to pass through. They are used for creating canopies and awnings over entrances, patios, and walkways.

4. Interior Partitions

In commercial and industrial spaces, PC hollow sheets can be used as lightweight, durable partitions that allow natural light to flow through the workspace. They can also offer a degree of privacy depending on the sheet's transparency level.

5. Sound Barriers

The sound insulation properties of PC hollow sheets make them suitable for use as sound barriers along highways or in industrial areas. They help reduce noise pollution while maintaining a visually appealing look.

6. Signage

Due to their durability and weather resistance, PC hollow sheets are often used for outdoor signage and advertising boards. Their transparency allows for backlighting, making them an excellent choice for illuminated signs.

7. Industrial Roofing

For factories and warehouses, PC hollow sheets are used as roofing material due to their high impact resistance and insulation properties. They help maintain a comfortable working environment by reducing the amount of heat entering the building.

Benefits of Using PC Hollow Sheets

1. Energy Efficiency

The Hollow Sheet Polycarbonate excellent thermal insulation properties help reduce energy costs by minimizing the need for heating or cooling in buildings.

2. Cost-Effective

Compared to glass or solid polycarbonate, hollow sheets are more affordable. They offer similar strength and light transmission at a lower cost, making them a budget-friendly solution for many projects.

3. Long Lifespan

The UV-resistant coating on PC hollow sheets ensures that they last for many years without yellowing or degrading. Their durability and impact resistance reduce the need for repairs or replacements, providing long-term value.

4. Easy Installation

The lightweight nature of PC hollow sheets makes them easy to transport, handle, and install, reducing labor costs and project timelines.

5. Aesthetic Appeal

With their sleek, modern appearance and the ability to bend or curve, PC hollow sheets enhance the aesthetic appeal of any structure, whether residential or commercial.

Installation Tips for PC Hollow Sheets

When installing PC hollow sheets, there are a few important considerations to keep in mind:

Cut to Size: Use a fine-tooth saw or a specialized cutting tool to cut the sheets to the required size.

Ensure Proper Support: Install the sheets on a sturdy framework, ensuring there’s adequate support to prevent sagging.

Allow for Expansion: Polycarbonate expands and contracts with temperature changes, so leave a small gap between sheets and frames to accommodate thermal movement.

Seal the Edges: Properly seal the edges of the sheets with a UV-protected sealing tape to prevent water, dust, and insects from entering the hollow channels.

Use Correct Fasteners: Use fasteners specifically designed for polycarbonate to ensure that the sheets are securely attached without causing stress cracks.

Conclusion

The Hollow Polycarbonate Sheet are an incredibly versatile, durable, and cost-effective building material. Whether you're constructing a greenhouse, installing a skylight, or creating a sound barrier, PC hollow sheets provide an excellent solution that combines functionality and aesthetics. Their lightweight nature, impact resistance, thermal insulation, and UV protection make them a reliable choice for a wide range of applications.

Frequently Asked Questions (FAQs)

1. What is the lifespan of PC hollow sheets?

PC hollow sheets typically last between 10 to 20 years, depending on the quality of the material and the installation. The UV coating helps prevent yellowing and degradation, extending their useful life.

2. Are PC hollow sheets better than glass?

Yes, in many cases, PC hollow sheets are better than glass. They are lighter, more impact-resistant, easier to install, and provide better insulation than glass. However, glass offers superior clarity, so the choice depends on the application.

3. Can PC hollow sheets be recycled?

Yes, PC hollow sheets are made from polycarbonate, a recyclable material. After their useful life, they can be recycled and repurposed for other products.

4. How do I clean PC hollow sheets?

PC hollow sheets can be cleaned using mild soap and water. Use a soft cloth or sponge to avoid scratching the surface, and never use abrasive cleaners or harsh chemicals.