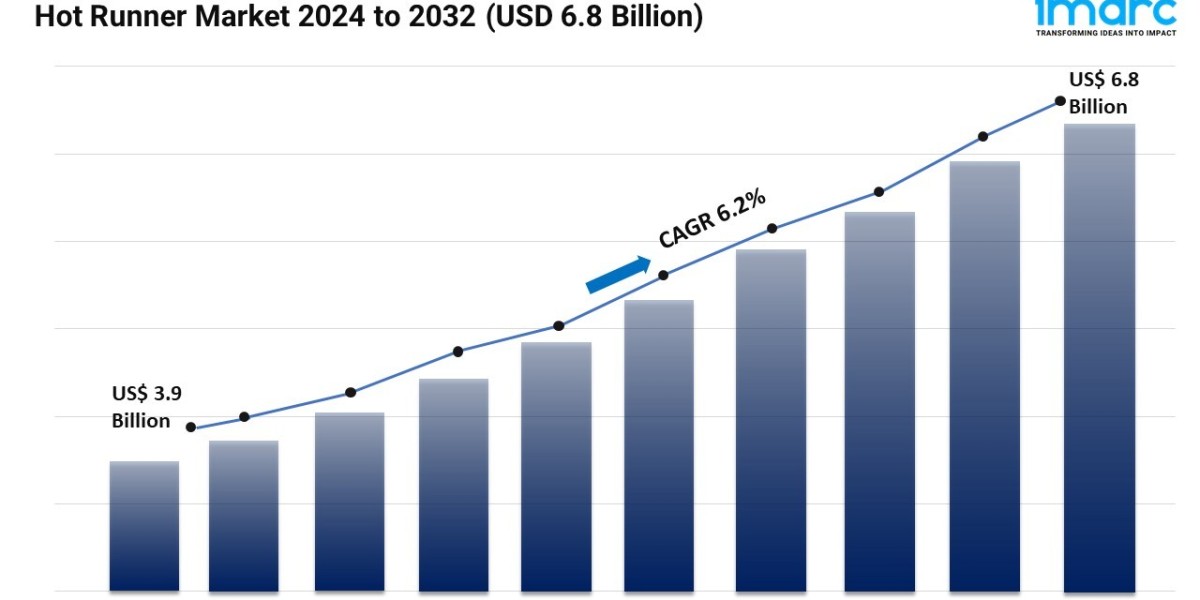

Global Hot Runner Industry: Key Statistics and Insights in 2024-2032

Summary:

- The global hot runner market size reached USD 3.9 Billion in 2023.

- The market is expected to reach USD 6.8 Billion by 2032, exhibiting a growth rate (CAGR) of 6.2% during 2024-2032.

- Asia Pacific leads the market, accounting for the largest hot runner market share.

- Automotive accounts for the majority of the market share owing to the growing reliance on injection molding for producing complex, durable automobile parts with high precision.

- Heated runners dominate the market due to their crucial role in maintaining consistent temperature and flow of plastic.

- Valve gate hot runners dominate the market due to their precise control over plastic flow.

- The growing demand for efficient molding processes is driving market growth.

- Innovations like precise temperature controls, advanced valve gate systems, and sophisticated nozzle designs are improving the performance of hot runner systems.

Request for a sample copy of this report: https://www.imarcgroup.com/hot-runner-market/requestsample

Industry Trends and Drivers:

- Rising Demand for Efficient Molding Processes:

The increasing demand for more efficient molding processes is propelling the growth of the market. Industries are seeking ways to increase production speed and reduce costs without compromising quality. Hot runner systems offer a solution by enabling faster cycle times and eliminating the need for runners, thereby reducing material waste. This efficiency not only improves productivity but also contributes to sustainability goals by minimizing raw material usage. The ability of hot runner systems to streamline the manufacturing process, reducing both time and material waste, makes them an essential component in modern injection molding operations.

- Technological Advancements:

Innovations, such as precise temperature controls, advanced valve gate systems, and sophisticated nozzle designs, benefit in enhancing the performance of hot runner systems. These improvements are making it possible to mold parts with higher precision, better surface quality, and reduced maintenance needs. Such technological progress addresses the limitations of traditional hot runner systems, such as material leakage and thermal degradation, making them more versatile and suitable for a broader range of materials and complex applications. Apart from this, key manufacturers are investing in durable and high-performance molding solutions, which is bolstering the market growth.

- Increasing Need for High-Quality Plastic Parts:

The rising demand for high-quality plastic parts with superior aesthetics and tight dimensional tolerances is impelling the market growth. Industries, such as automotive and electronics, are producing parts that not only meet functional requirements but are also visually appealing to individuals. Hot runner systems aid in offering better control over the injection molding process, resulting in parts with consistent quality, minimal defects, and superior surface finishes. This ability to meet high-quality standards is particularly important in competitive markets where product appearance and quality can impact consumer preference and brand reputation.

The hot runner market forecast offers insights into future opportunities and challenges, drawing on historical data and predictive modeling.

Hot Runner Market Report Segmentation:

By Gate Type:

- Valve Gate Hot Runner

- Open Gate Hot Runner

Valve gate hot runner exhibits a clear dominance in the market due to their precise control over the flow of plastic, leading to higher quality products and efficiency in large-scale production.

By Product Type:

- Insulated Runner

- Heated Runner

Heated runner represents the largest segment as it is essential for maintaining consistent temperature and flow of the plastic.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific dominates the market, driven by its large manufacturing base and the increasing adoption of advanced manufacturing technologies.

Top Hot Runner Market Leaders:

The hot runner market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Barnes Group Inc.

- CACO PACIFIC Corporation

- EWIKON Heißkanalsysteme GmbH

- Fast Heat UK Limited

- FISA Corporation

- GÜNTHER Heisskanaltechnik GmbH

- Husky Injection Molding Systems Ltd.

- INCOE Corporation

- Inglass S.p.A (OC Oerlikon Management AG)

- Milacron Holdings Corp. (Hillenbrand Inc.)

- Seiki Corporation

- Yudo Co. Ltd.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145