Introduction

Conductive ink is one of the major ingredients in the printing of metal structures. It can be formulated by blending either nanoparticles or micron-sized particles that are highly conductive such as silver, gold, copper, zinc, or carbon.

Conductive Inks are of different types, such as silver, copper, carbon/graphene, carbon nanotube, and conductive polymer, that are used in various applications, such as photovoltaics, RFID, PCB, membrane switches, displays, bio-sensors, thermal heating.

The conductive ink market is witnessing significant growth, driven by the rising demand for advanced electronics, printed circuit boards (PCBs), and innovative applications in various industries. Conductive inks, which contain materials like silver, copper, or carbon, enable electricity to flow through printed patterns, replacing traditional wiring systems and contributing to the miniaturization and flexibility of electronic components. This market is projected to grow rapidly as technology advancements and sustainability concerns reshape the landscape of modern electronics.

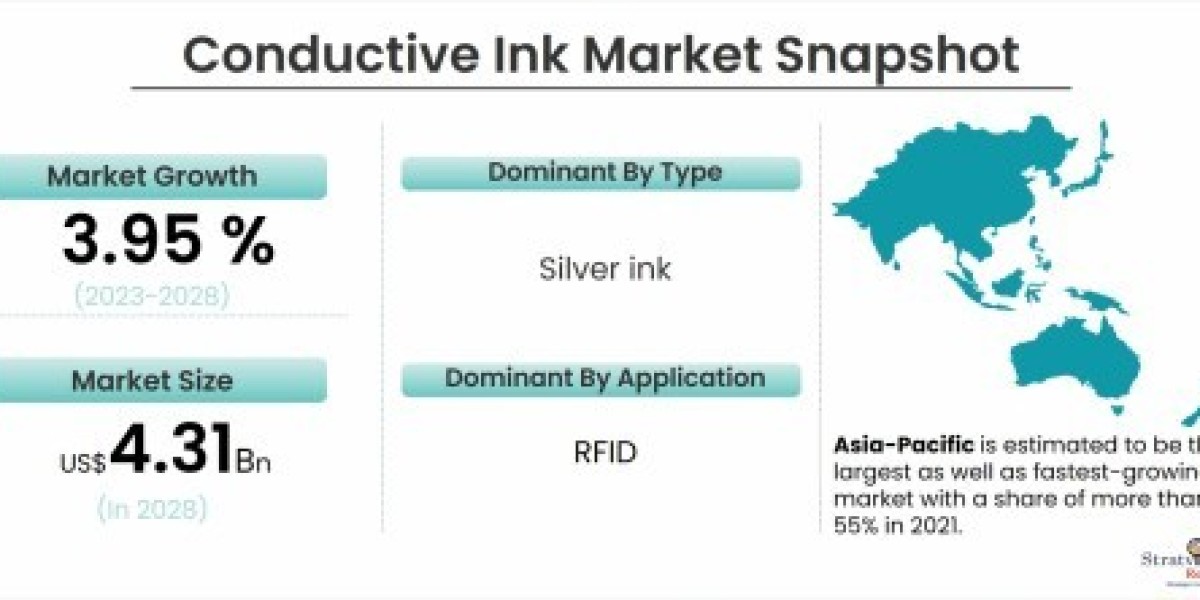

The conductive ink market is estimated to grow from USD 3.5 billion in 2023 to USD 4.31 billion by 2028 at a CAGR of 3.95% during the forecast period.

Key Trends Driving Market Growth

- Flexible and Printed Electronics: One of the most prominent factors boosting the conductive ink market is the increasing adoption of flexible electronics. Devices like flexible displays, wearable sensors, and smart packaging require conductive inks for their production. The ability of conductive ink to form highly flexible and durable circuits is fueling demand in this sector.

- Automotive and Aerospace Applications: Conductive inks are playing an integral role in the automotive and aerospace industries, where they are used in sensors, heaters, and touch-sensitive controls. As vehicles and aircraft become more reliant on sophisticated electronics, the use of lightweight and efficient conductive materials helps reduce overall weight and improve performance.

- Renewable Energy Systems: The push for more sustainable energy solutions is another key driver for the conductive ink market. In solar panel production, conductive inks are being used to develop cost-effective and high-efficiency solar cells. Similarly, in the energy storage and fuel cell markets, these inks are contributing to innovations that make systems more reliable and efficient.

- Healthcare Innovations: The healthcare industry is seeing an increase in the use of conductive inks for wearable medical devices and sensors. These innovations enable real-time health monitoring and improve patient care, offering a huge growth opportunity for the conductive ink market in personalized medicine and diagnostics.

Future Prospects and Challenges

While the conductive ink market is poised for significant growth, challenges remain in terms of cost and performance. Silver-based inks, which are the most commonly used, are expensive, leading to ongoing research into alternatives like copper and graphene. Moreover, ensuring the long-term reliability of conductive ink in harsh environments continues to be a critical focus area.

Overall, the conductive ink market is on a trajectory of steady expansion, driven by a wide range of applications in electronics, automotive, aerospace, and healthcare. With ongoing advancements in material science, this market is expected to play a key role in shaping the future of electronics manufacturing and sustainable technologies.

To read in detail about the market dynamics, Click Here: https://www.stratviewresearch.com/Request-Sample/915/conductive-ink-market.html#form