The vibration monitoring market is experiencing significant growth, fueled by technological advancements and increasing awareness of the importance of equipment health. However, this growth also comes with a set of challenges that industry stakeholders must navigate to fully capitalize on the opportunities presented by this evolving landscape.

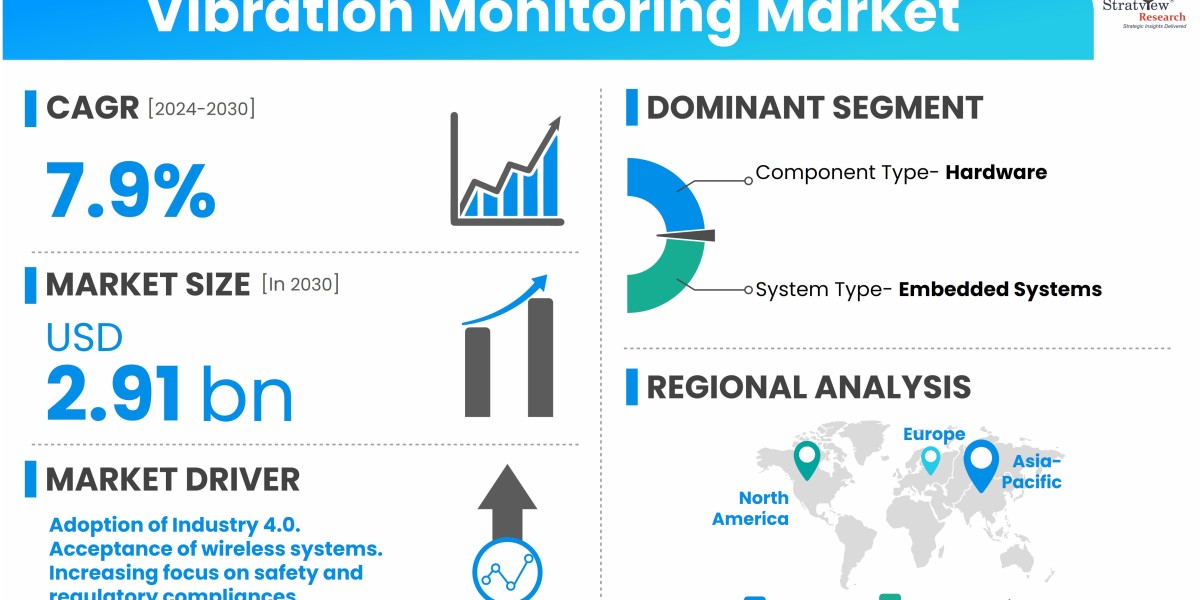

According to Stratview Research, the vibration monitoring market was estimated at USD 1.7 billion in 2023 and is likely to grow at a CAGR of 7.9% during 2024-2030 to reach USD 2.91 billion in 2030.

Challenges

- High Initial Costs: Implementing vibration monitoring systems can require significant upfront investment. The costs associated with advanced sensors, software, and integration with existing systems may deter small and medium-sized enterprises (SMEs) from adopting these technologies. According to a report by Grand View Research, the initial expense can limit market penetration, especially in cost-sensitive industries.

- Data Management Complexity: As organizations collect vast amounts of data from vibration monitoring systems, managing and analyzing this data effectively becomes a challenge. The complexity of data management can overwhelm companies lacking the necessary infrastructure or expertise. Many businesses may struggle to extract actionable insights from the data collected, which can hinder decision-making processes and reduce the effectiveness of monitoring systems.

- Lack of Skilled Workforce: The rapid evolution of vibration monitoring technologies necessitates a workforce skilled in data analysis, sensor technologies, and predictive maintenance strategies. However, there is often a shortage of qualified personnel who can operate and interpret these advanced systems. This skills gap can impede the successful implementation of vibration monitoring solutions.

Opportunities

- Rising Demand for Predictive Maintenance: Despite the challenges, the growing trend toward predictive maintenance presents a significant opportunity for the vibration monitoring market. As industries seek to reduce downtime and optimize maintenance schedules, the need for effective monitoring solutions will continue to rise. Businesses that can successfully implement these systems will enhance operational efficiency and reduce costs.

- Advancements in Technology: Continuous advancements in sensor technology, machine learning, and data analytics are creating new opportunities within the vibration monitoring market. For example, the integration of IoT devices allows for real-time monitoring and analysis, enabling organizations to detect issues before they lead to equipment failure. This technological evolution can drive down costs and improve the reliability of monitoring systems.

- Expanding Applications Across Industries: Vibration monitoring applications are expanding beyond traditional sectors such as manufacturing and oil and gas. Industries like healthcare, automotive, and renewable energy are increasingly adopting these technologies to ensure equipment reliability and safety. This diversification offers a broader market scope and new growth avenues for providers.

Conclusion

While the vibration monitoring market faces challenges related to costs, data management, and workforce skills, the opportunities driven by predictive maintenance, technological advancements, and expanding applications present a compelling case for continued investment and development. Companies that can address these challenges effectively will be well-positioned to thrive in this dynamic market.