The footwear manufacturing industry is one of the most competitive sectors globally, requiring stringent adherence to quality and safety standards. ISO certifications provide a structured approach for manufacturers to enhance efficiency, maintain product quality & meet international regulations. By adopting ISO standards, footwear manufacturers ensure consumer safety and satisfaction and also establish their brand as a trustworthy and eco-conscious entity.

Looking for ISO certification for footwear manufacturing? Contact us today at support@pacificcert.com or call us at +91–8595603096 for expert guidance.

Applicable ISO Standards for Footwear Manufacturing

ISO 9001: Quality Management: ISO 9001 is the cornerstone of quality assurance. It enables footwear manufacturers to maintain consistency in product quality, streamline operations, and foster customer satisfaction.

ISO 14001: Environmental Management: With growing concerns about environmental impact, ISO 14001 helps manufacturers implement sustainable practices by reducing waste, conserving energy, and minimizing their ecological footprint.

ISO 45001: Occupational Health and Safety: Worker safety is paramount in manufacturing. ISO 45001 ensures that footwear factories have adequate safety measures to protect employees from workplace hazards.

ISO 26000: Social Responsibility: This standard emphasizes ethical practices, fair labor conditions, and community engagement, aligning businesses with social accountability goals.

ISO 50001: Energy Management: ISO 50001 guides manufacturers in optimizing energy use, reducing costs, and achieving long-term energy sustainability.

Click here to find out more applicable standards to your industry

We, at Pacific Certifications, specialize in providing audit and certification services for ISO standards. Our expert team ensures a seamless certification process tailored to the needs of footwear manufacturers. From initial assessment to final certification, we focus on maintaining transparency and integrity.

Interested in obtaining ISO certification for your footwear manufacturing business? Email us at support@pacificcert.com or call +91–8595603096 for a seamless experience!

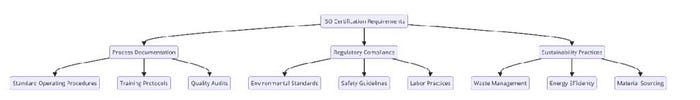

Requirements of ISO Certifications for Footwear Manufacturing

Here are the specific requirements for each ISO standard applicable to footwear manufacturing:

ISO 9001: Quality Management System (QMS)

- Documented Quality Policy: Clear objectives aligning with customer needs and regulatory compliance.

- Process Standardization: Defined and standardized procedures for all manufacturing and quality-related activities.

- Risk-Based Thinking: Identification and mitigation of risks affecting product quality.

- Customer Focus: Strategies to enhance customer satisfaction, including handling complaints effectively.

- Performance Monitoring: Regular evaluation through internal audits and management reviews.

- Continuous Improvement: A system for tracking and improving processes and products.

ISO 14001: Environmental Management System (EMS)

- Environmental Policy: Commitment to sustainability and regulatory compliance.

- Identification of Environmental Aspects: Assessment of the environmental impact of production processes.

- Legal Compliance: Adherence to local and international environmental laws.

- Waste Management: Procedures for reducing, reusing, and recycling waste materials.

- Energy Efficiency: Initiatives to conserve energy and minimize greenhouse gas emissions.

- Emergency Preparedness: Plans to handle environmental incidents effectively.

ISO 45001: Occupational Health and Safety Management System

- Hazard Identification: Recognition and assessment of potential workplace risks.

- Risk Mitigation Plans: Implementation of safety measures to prevent accidents and injuries.

- Employee Participation: Involvement of workers in developing and improving safety measures.

- Compliance with Safety Regulations: Adherence to occupational health and safety laws.

- Training Programs: Regular training for employees on safety procedures and emergency protocols.

- Incident Management: Procedures for reporting, investigating, and resolving safety incidents.

ISO 26000: Social Responsibility

- Ethical Practices: Transparent and accountable business operations.

- Fair Labor Policies: Ensuring non-discriminatory and inclusive workplace conditions.

- Community Involvement: Active contribution to social and economic development.

- Consumer Protection: Commitment to producing safe, high-quality footwear.

- Sustainability Initiatives: Actions promoting environmental and social well-being.

ISO 50001: Energy Management System (EnMS)

- Energy Policy: Commitment to energy efficiency and sustainable practices.

- Energy Baseline: Determination of current energy usage as a benchmark for improvements.

- Energy Performance Indicators (EnPIs): Metrics to monitor and evaluate energy efficiency.

- Energy Objectives and Plans: Setting targets to reduce energy consumption.

- Operational Controls: Implementation of energy-efficient technologies and practices.

- Continual Improvement: Regular reviews and updates to energy management strategies.

By adhering to the requirements of these ISO standards, footwear manufacturers can achieve excellence in quality, sustainability, safety, and operational efficiency. For more details or to begin the certification process, contact us today!

Contact support@pacificcert.com or call us at +91–8595603096 for professional support.

Read More: ISO Certifications for Footwear Manufacturing Businesses