In today's fast-paced world, businesses are constantly looking for ways to increase efficiency and productivity. One such solution that has gained popularity in recent years is the use of welding robots. These automated machines are capable of performing a wide range of welding tasks with precision and accuracy, making them an invaluable asset for both small and large businesses. In this article, we will explore the advantages of welding robot and how they can benefit businesses of all sizes.

What are Welding Robots?

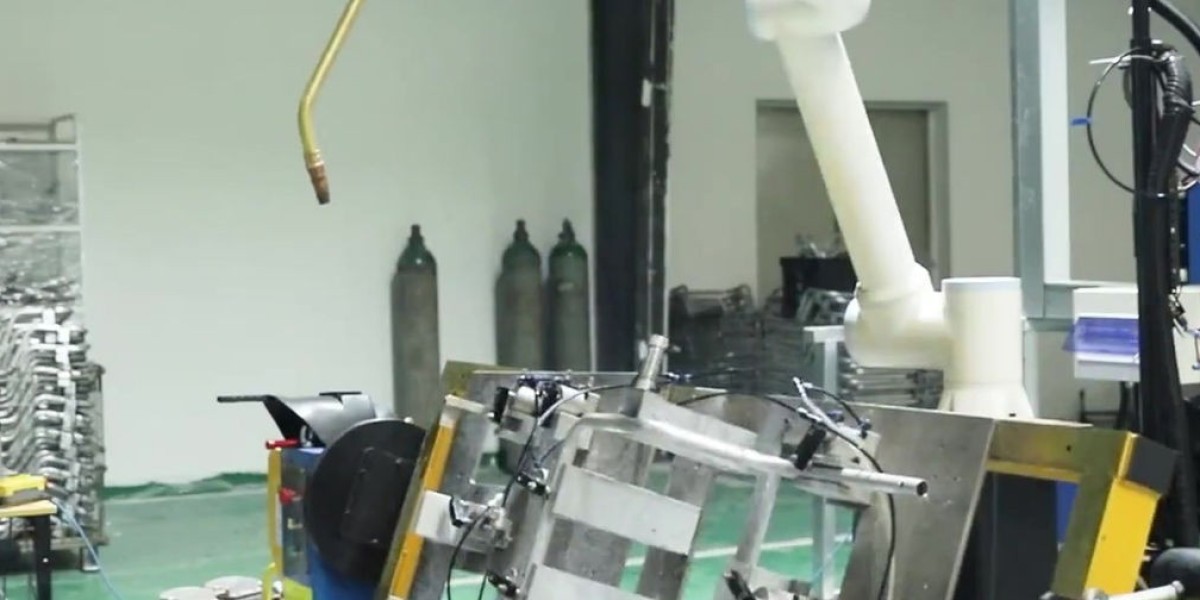

Before diving into the benefits of welding robots, let's first understand what they are. Welding robots are automated machines that are programmed to perform welding tasks with speed and precision. These robots are equipped with advanced sensors and software that allow them to weld various materials, shapes, and sizes with minimal human intervention. By using welding robots, businesses can increase efficiency, improve quality, and reduce labor costs.

Key Advantages of Welding Robots for Businesses

- Increased Productivity: One of the biggest advantages of welding robots is their ability to work faster and more efficiently than human welders. These robots can work around the clock without getting tired, resulting in higher productivity levels for businesses. With welding robots, businesses can complete more projects in less time, leading to increased profitability.

- Improved Quality: Welding robots are programmed to weld with precision and accuracy, ensuring consistent quality in every weld. This results in fewer defects and rework, saving businesses time and money. By using welding robots, businesses can deliver high-quality products to their customers, leading to increased customer satisfaction and loyalty.

- Cost Savings: While the initial investment in welding robots may be high, businesses can save money in the long run by reducing labor costs and improving efficiency. Welding robots can work faster and more accurately than human welders, resulting in lower production costs and higher profits. Additionally, welding robots require minimal maintenance and can last for many years, providing businesses with a cost-effective solution for their welding needs.

- Safety: Welding can be a dangerous task, with risks of burns, injuries, and exposure to harmful fumes. By using welding robots, businesses can improve safety in the workplace by reducing the need for human welders to perform dangerous tasks. This not only protects workers from harm but also reduces the risk of workplace accidents and liabilities for businesses.

- Versatility: Welding robots are capable of welding a wide range of materials, shapes, and sizes, making them a versatile solution for businesses with diverse welding needs. These robots can be programmed to perform various welding techniques, such as arc welding, spot welding, and laser welding, giving businesses the flexibility to adapt to different welding projects.

Conclusion

In conclusion, welding robots offer numerous advantages for businesses of all sizes, including increased productivity, improved quality, cost savings, safety, and versatility. By investing in welding robots, businesses can streamline their welding processes, reduce labor costs, and deliver high-quality products to their customers. With the advanced technology and capabilities of welding robots, businesses can stay competitive in today's market and achieve long-term success. So, why wait? Explore the benefits of welding robots for your business today!