The ceramic additive manufacturing market is a rapidly growing segment within the broader 3D printing industry. Ceramic materials, known for their superior thermal, mechanical, and chemical properties, are being increasingly utilized across various industries, such as aerospace, healthcare, automotive, and electronics.

The ceramic additive manufacturing market size was valued at USD 584.69 million in 2023 and is projected to grow to USD 716.83 million in 2024, reaching USD 4,208.22 million by 2032. This represents a compound annual growth rate (CAGR) of 24.8% during the forecast period (2024–2032).

Key Market Drivers

1. Rising Demand in Aerospace and Defense

Ceramics offer exceptional resistance to high temperatures, corrosion, and wear, making them ideal for aerospace and defense applications. Additive manufacturing allows for the production of lightweight, high-strength components, such as turbine blades and thermal shields, which are critical for improving fuel efficiency and performance.

2. Advancements in Medical Applications

Ceramic materials, such as zirconia and alumina, are widely used in medical implants due to their biocompatibility and durability. Additive manufacturing enables the production of patient-specific implants and prosthetics with complex geometries, enhancing the effectiveness of treatments.

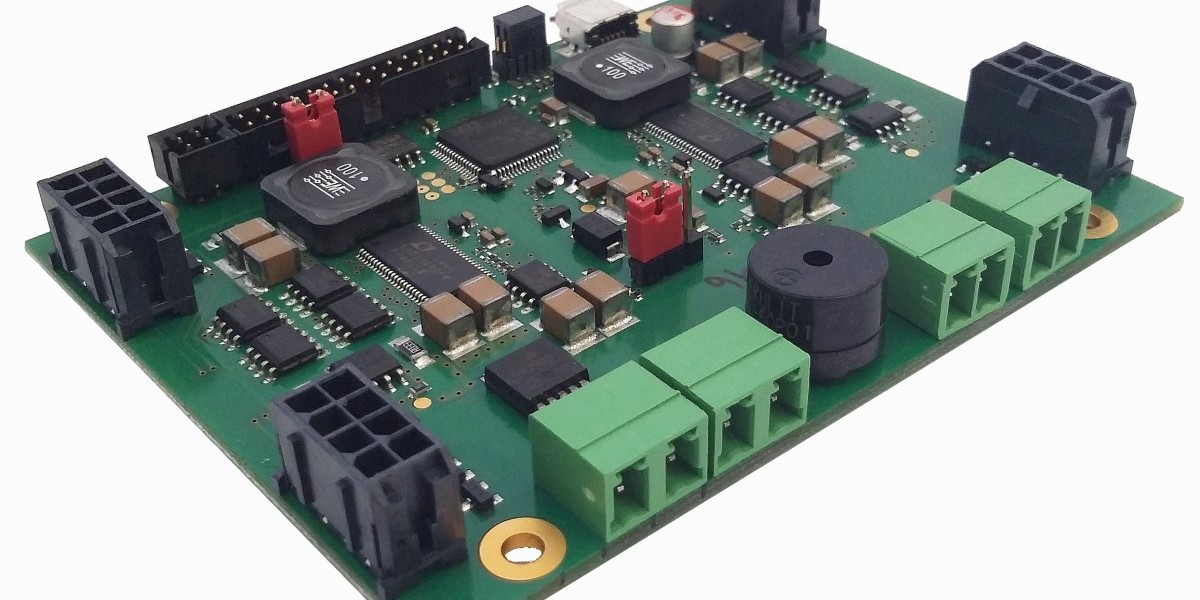

3. Growing Adoption in Electronics

The miniaturization of electronic components and the need for materials with excellent thermal and electrical insulation properties are driving the use of ceramics in electronics. Ceramic AM facilitates the rapid prototyping and production of custom components, such as insulators and circuit boards, catering to the evolving needs of the electronics industry.

4. Sustainability and Cost-Effectiveness

Additive manufacturing minimizes material wastage compared to traditional subtractive methods. Additionally, the ability to produce parts on demand reduces inventory costs and transportation emissions, aligning with sustainability goals.

5. Technological Advancements

Innovations in AM technologies, such as binder jetting, stereolithography (SLA), and digital light processing (DLP), have improved the quality, speed, and cost-efficiency of ceramic 3D printing. These advancements are expanding the range of applications and driving market growth.

Some of the key players in the Ceramic Additive Manufacturing Companies are Desktop Metal Inc., SiNAPTIC, Ceram Tech, Lithoz, Voxeljet, XJet, Renishaw, Dyson Technical Ceramics, 3D, Ceram Sinto, Admatec, Kwambio, Nanoe, Tethon 3D, Prodways, 3D Systems and Kyocera International

Key Trends in the Ceramic Additive Manufacturing Market

1. Integration of AI and Machine Learning

AI and machine learning are being leveraged to optimize AM processes, predict material behavior, and improve the quality of ceramic components.

2. Customization and Personalization

The ability of AM technologies to produce customized products is driving their adoption in industries like healthcare, where patient-specific implants are in high demand.

3. Multi-Material Printing

Innovations in multi-material printing are enabling the combination of ceramics with metals or polymers, expanding the functionality of AM-produced components.

4. Expansion of Material Portfolio

Manufacturers are developing new ceramic materials with enhanced properties, such as increased toughness and thermal stability, to cater to diverse applications.

5. Focus on Energy Efficiency

Energy-efficient AM systems and processes are gaining traction, aligning with the industry's efforts to reduce environmental impact.

Browse Full Report: Ceramic Additive Manufacturing Market Share

Challenges in the Ceramic AM Market

High Production Costs

The cost of ceramic materials and AM equipment remains high, limiting adoption in cost-sensitive industries.Complex Post-Processing Requirements

Ceramic parts often require extensive post-processing, such as sintering and polishing, which can increase production time and costs.Limited Awareness and Expertise

The adoption of ceramic AM technologies is hindered by a lack of awareness and skilled professionals in certain regions and industries.

About Market Research Future

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us

Market Research Future (part of WantStats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: sales@marketresearchfuture.com

Website: https://www.marketresearchfuture.com