Understanding the Global Vibration Monitoring Market: Growth, Challenges, and Opportunities

The global vibration monitoring market has witnessed substantial growth over the past few years, driven by the increasing need for predictive maintenance and real-time monitoring of machinery performance. Vibration monitoring is an essential process in industrial operations, where detecting and analyzing vibrations from equipment and machinery helps in identifying potential failures, preventing downtime, and optimizing performance. As industries increasingly focus on efficiency, safety, and cost reduction, the demand for advanced vibration monitoring systems is expected to surge.

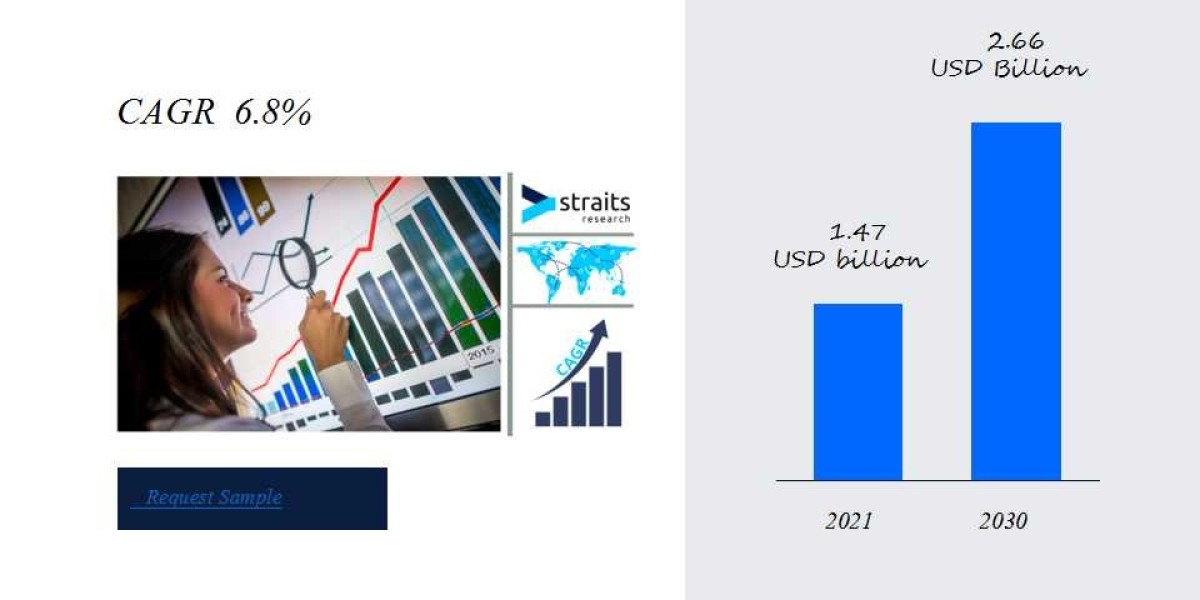

According to Straits Research, the global vibration monitoring market was valued at USD 1.47 billion in 2021 and is projected to reach USD 2.66 billion by 2030, growing at a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period from 2022 to 2030.

Request Sample Link Of Link:https://straitsresearch.com/report/vibration-monitoring-market/request-sample

Industry Dimensions

Definition and Market Value:

Vibration monitoring involves the process of measuring and analyzing vibrations emitted by industrial equipment, machinery, and structures to detect signs of wear, imbalances, or mechanical faults. This is an important part of predictive maintenance in industries such as oil and gas, energy, automotive, manufacturing, and more.

The market size was valued at USD 1.47 billion in 2021, and it is expected to grow to USD 2.66 billion by 2030, reflecting a healthy growth rate of 6.8%. This expansion is being fueled by the increasing adoption of industrial automation, the rising focus on machine reliability, and the implementation of IoT (Internet of Things) technologies in vibration monitoring systems.

Key Industry Trends

Integration with IoT and AI: The integration of IoT, Artificial Intelligence (AI), and machine learning technologies in vibration monitoring systems is a growing trend. These technologies help in collecting real-time data, enabling predictive analysis and condition-based maintenance.

Shift to Predictive Maintenance: There is a significant shift towards predictive maintenance over traditional reactive maintenance methods, as businesses seek to reduce operational downtime and maintenance costs.

Advancements in Sensor Technology: The development of more accurate, durable, and affordable vibration sensors is accelerating the adoption of vibration monitoring systems. These sensors are now capable of detecting even the smallest vibrations with high precision.

Cloud-based Monitoring Systems: Cloud technology allows for remote monitoring and data storage, improving accessibility and enabling faster decision-making by plant managers and maintenance teams.

Focus on Industrial Automation: As industries increasingly embrace automation, the need for continuous monitoring of industrial assets has risen, further driving the demand for vibration monitoring systems.

Energy Efficiency and Sustainability Initiatives: Vibration monitoring systems help in optimizing equipment efficiency, contributing to energy savings and sustainability goals by minimizing downtime and energy wastage.

Vibration Monitoring Market Size and Share

The vibration monitoring market's growth trajectory can be attributed to multiple factors including the global push towards Industry 4.0, increasing awareness about the benefits of predictive maintenance, and the rising importance of minimizing machine downtime. The market is expected to grow from USD 1.47 billion in 2021 to USD 2.66 billion by 2030.

Key factors influencing market growth include:

- Increasing demand for real-time monitoring in industries like automotive, oil & gas, and power generation.

- Technological advancements in sensors, which enable more accurate detection of vibration patterns and failure prediction.

- Rising industrial automation and the need for continuous performance monitoring.

Regional Trends

North America

North America holds a significant share in the global vibration monitoring market. The demand is primarily driven by the U.S. and Canada, where industries such as automotive, energy, oil & gas, and manufacturing are early adopters of advanced monitoring technologies. The presence of leading market players, such as Emerson Electric and General Electric, also contributes to the growth in the region. The need for predictive maintenance and reduced downtime in critical industries drives the demand for vibration monitoring systems in North America.

Asia-Pacific (APAC)

The APAC region is expected to witness the highest growth during the forecast period. Countries like China, Japan, South Korea, and India are heavily investing in industrial automation and smart factory solutions, which are key drivers of demand for vibration monitoring systems. The rapid expansion of the manufacturing, automotive, and energy sectors in APAC is expected to propel the market in this region. The increasing adoption of IoT-based monitoring systems and the growing industrial base make APAC an attractive market for vibration monitoring solutions.

Europe

Europe is another key market for vibration monitoring, with Germany, France, and the UK being the major contributors. The automotive and energy sectors in Europe are increasingly adopting predictive maintenance and vibration monitoring solutions to improve equipment reliability and reduce operational costs. With stringent regulations regarding industrial safety and equipment performance, Europe continues to be a significant market for vibration monitoring systems.

LAMEA (Latin America, Middle East, and Africa)

The LAMEA region is poised for steady growth, particularly in countries like Brazil, South Africa, and the UAE. The oil and gas industry in the Middle East, along with increasing industrialization in Latin America, are expected to drive the demand for vibration monitoring solutions in this region. However, the market in this region is still in its nascent stage compared to North America and Europe, with slower adoption rates of advanced technologies.

Vibration Monitoring Market Segmentations

By Component

- Hardware: Includes sensors, accelerometers, and other vibration monitoring instruments used for measuring vibrations in industrial machinery.

- Software: Encompasses data analysis and predictive maintenance software, cloud-based platforms, and applications for monitoring and visualization.

- Services: Includes installation, calibration, and maintenance services provided by vibration monitoring system vendors.

By System Type

- Embedded Systems: These systems are integrated into machines for real-time vibration monitoring, providing constant feedback on machine health.

- Vibration Analyzers: These devices are used to analyze vibration signals, helping to detect problems such as misalignments or imbalances.

- Vibration Meters: Portable devices used to measure vibration levels across machines and industrial equipment.

By Monitoring Process

- Online: Continuous, real-time monitoring systems installed directly onto machinery for constant data transmission and analysis.

- Portable: Standalone devices that are used intermittently to measure vibration levels, often used in maintenance and troubleshooting scenarios.

By End-Use

- Energy and Power: The need for reliable and efficient energy production drives the demand for vibration monitoring systems in power plants and electrical grids.

- Metals and Mining: Vibration monitoring is essential in detecting wear and tear in mining equipment and ensuring operational efficiency.

- Oil and Gas: The oil and gas industry heavily relies on vibration monitoring to ensure the smooth operation of equipment like pumps, compressors, and turbines.

- Automotive: Manufacturers use vibration monitoring to improve vehicle performance and detect issues early in production lines.

- Food and Beverages: Vibration monitoring in this industry ensures equipment runs efficiently, helping to avoid product contamination and production delays.

- Others: Other industries that benefit from vibration monitoring include aerospace, chemical processing, and pharmaceuticals.

Top Players in the Vibration Monitoring Market

Several leading players in the market are continually advancing their vibration monitoring technologies to meet the growing demands of industries across the globe. Some of the top players include:

- SKF AB

- Emerson Electric Co.

- General Electric

- Meggitt PLC

- National Instruments Corp.

- Rockwell Automation Inc.

- Honeywell International Inc.

- Schaeffler Technologies AG & Co. KG

- Bruel & Kjaer Sound & Vibration Measurement A/S

- Analog Devices Inc.

Buy Now:https://straitsresearch.com/buy-now/vibration-monitoring-market

These companies are focusing on strategic partnerships, acquisitions, and the development of advanced vibration monitoring systems to enhance their market presence.

About Straits Research

Straits Research is a top-tier provider of business intelligence, specializing in research, analytics, and advisory services. The company’s in-depth reports provide actionable insights that assist businesses in making informed decisions. Straits Research’s comprehensive studies focus on emerging trends, key market drivers, and industry opportunities, helping clients navigate complex markets and stay ahead of the competition.