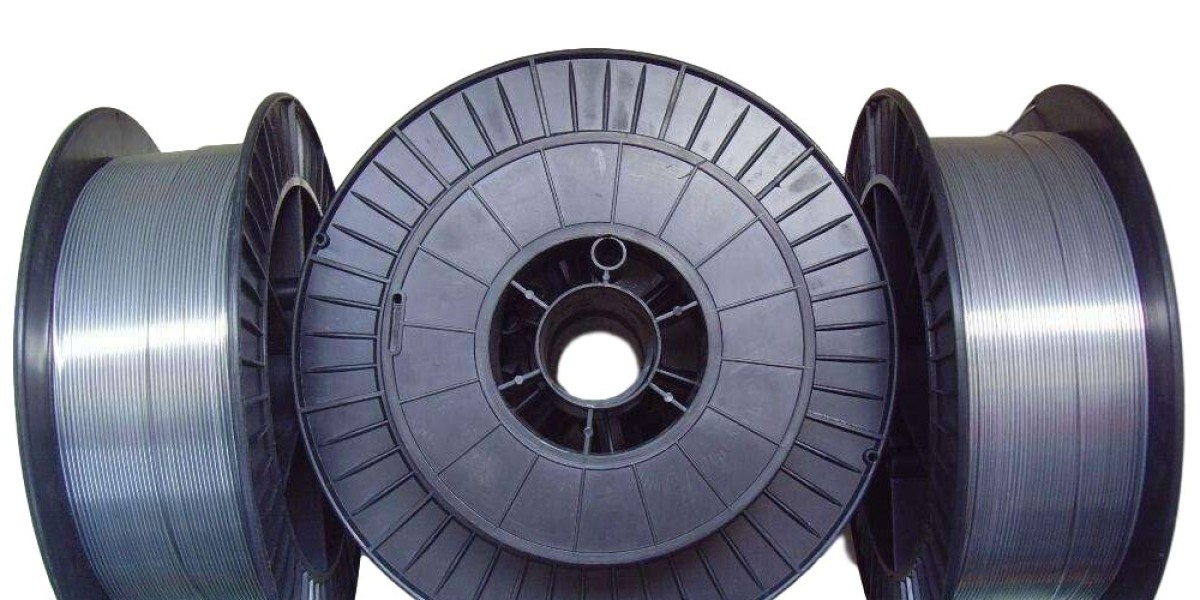

The welding consumable market has experienced significant growth over the past few years, driven by several global trends and technological advancements. As industries across the world continue to expand, the demand for high-quality, reliable welding consumables is reaching new heights. This presents numerous opportunities for businesses to capitalize on emerging market needs and tap into the potential for long-term growth.

One of the key drivers of the welding consumable market is the increasing demand for welding in construction, automotive, aerospace, and heavy machinery industries. As these sectors grow and innovate, the need for advanced materials and welding consumables that can withstand extreme conditions has surged. This growing demand has opened up significant opportunities for manufacturers to supply consumables that meet the ever-evolving requirements of these industries.

In addition to traditional applications, technological advancements in welding processes are also driving change. The emergence of automated welding, robotic welding, and additive manufacturing is altering how welding is performed and, in turn, influencing the consumables market. Automation and robotics, in particular, are improving the efficiency and precision of welding operations. As a result, manufacturers are focusing on developing welding consumables that enhance the performance of these automated systems. With more industries adopting these technologies, there is an increasing need for consumables that can seamlessly integrate into these automated workflows.

Furthermore, the shift towards sustainable and eco-friendly practices in various industries is shaping the welding consumables market. Many companies are now emphasizing the use of environmentally friendly materials in their welding processes. The development of low-emission, recyclable, and energy-efficient consumables is opening up opportunities for manufacturers to align with the growing demand for green and sustainable practices. This trend is likely to gain momentum as environmental regulations become stricter and industries are pushed to reduce their carbon footprints.

The rising popularity of hybrid and electric vehicles (EVs) is another key factor contributing to the growth of the welding consumable market. The automotive industry’s shift toward EV production requires specialized welding materials that can withstand the unique demands of electric vehicle manufacturing. For instance, welding consumables must be capable of handling lightweight materials like aluminum and high-strength steel, which are commonly used in EVs. As the EV market continues to grow, the demand for specialized welding consumables will continue to rise.

Geographically, the welding consumable market presents unique opportunities in both developed and emerging regions. In developed countries, industrial expansion and modernization of existing infrastructure continue to drive demand for welding consumables. On the other hand, emerging markets in Asia, Africa, and Latin America are witnessing rapid industrialization, creating new opportunities for businesses to introduce their products to untapped markets. As these regions experience industrial growth, the need for high-quality welding consumables is expected to rise significantly.

To capitalize on these trends, businesses must focus on innovation, quality, and customer-centric approaches. Continuous research and development in welding technology will enable manufacturers to offer products that cater to diverse customer needs. Additionally, establishing strong distribution networks and forging strategic partnerships will allow companies to expand their reach in both established and emerging markets.

Another key opportunity in the welding consumable market lies in the growing adoption of digital technologies. The use of data analytics, Internet of Things (IoT), and smart sensors in welding operations is helping manufacturers optimize the performance of their consumables. These technologies allow for real-time monitoring and control, leading to improved weld quality, efficiency, and cost-effectiveness. As digitalization continues to shape industries worldwide, there is immense potential for companies to leverage these technologies to enhance the performance of their welding consumables.

In conclusion, the welding consumable market is poised for significant growth, driven by technological advancements, the demand for sustainable solutions, and the expansion of key industries. By staying ahead of emerging trends, manufacturers and suppliers can position themselves to capitalize on the vast opportunities this market offers. The continued focus on innovation and the ability to adapt to changing market dynamics will be key to unlocking the full potential of the welding consumable market in the coming years.