Double Block and Bleed (DBB) valves are critical components in industrial piping systems where safety, efficiency, and reliability are paramount. These valves provide a secure method of isolating process fluids, ensuring no leakage occurs during maintenance or system operations. Commonly used in industries such as oil & gas, petrochemicals, and power plants, DBB valves play a vital role in preventing contamination and enhancing operational safety.

Working Principle of DBB Valves

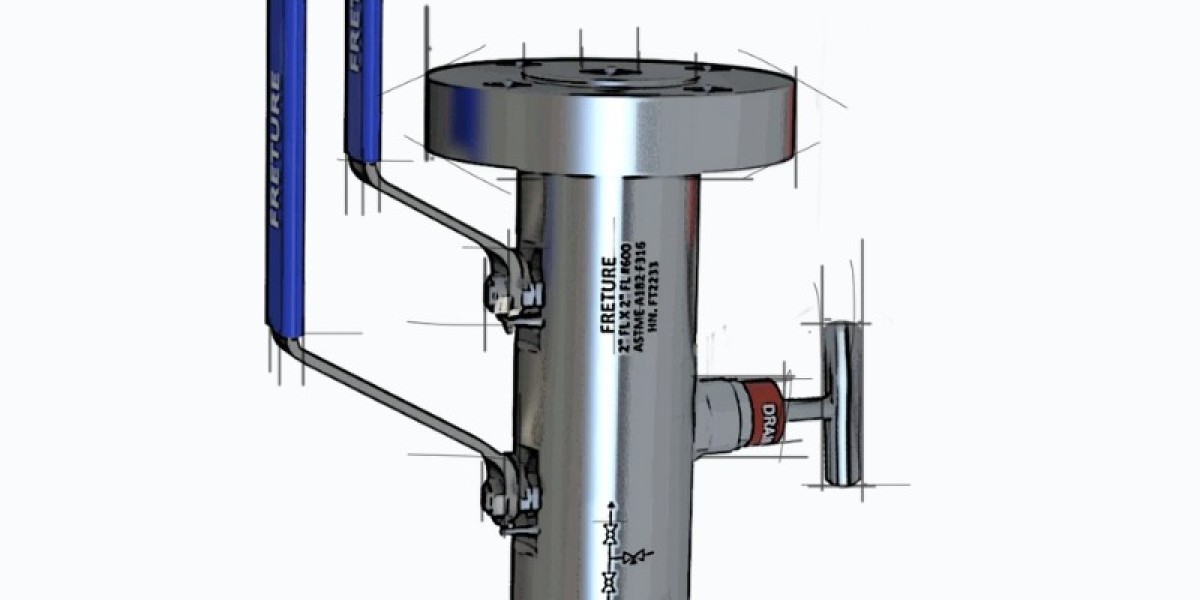

DBB valves function by using two separate sealing mechanisms, typically ball, gate, or needle valves, positioned in series with a bleed valve in between. This design allows for complete isolation of fluids, ensuring no pressure or leakage remains between the two block valves. The bleed function is used to drain or vent trapped fluids, enhancing safety during maintenance or inspections. This mechanism is essential for operations requiring strict isolation and zero leakage to prevent hazardous situations.

Types of Double Block and Bleed Valves

Several variations of DBB valves exist, each suited to specific industrial needs. Some common types include:

1. Integral DBB Valves

These valves integrate all three functions—two block valves and a bleed valve—into a single compact unit, reducing potential leakage points and overall weight. They are commonly used in high-pressure applications where space and weight constraints exist.

2. Modular DBB Valves

Modular DBB valves are designed with separate valve components assembled as a single unit. They provide greater flexibility in maintenance and customization based on industry requirements.

3. Twin Ball DBB Valves

This type features two ball valves with a bleed valve positioned between them. Twin ball DBB valves provide superior sealing and are ideal for high-integrity applications requiring complete isolation.

Applications of DBB Valves

DBB valves are extensively used in various industries, including:

Oil & Gas: Used in pipeline isolation, metering skids, and pressure monitoring systems to prevent cross-contamination and ensure system integrity.

Petrochemicals: Essential in refining and chemical processing plants to maintain operational safety by preventing hazardous leaks.

Power Plants: Used in steam and water systems for controlled isolation during maintenance.

Water Treatment: Helps in the isolation of high-pressure lines to ensure safe and efficient system performance.

Advantages of Double Block and Bleed Valves

DBB valves offer numerous advantages, making them an essential component in industrial fluid systems. Key benefits include:

1. Leak Prevention

The dual-block design ensures a tight seal, eliminating the risk of fluid leakage that can cause contamination or safety hazards.

2. Enhanced Safety

By allowing complete isolation and pressure relief, DBB valves protect workers and equipment from exposure to hazardous fluids or high-pressure failures.

3. Reduced Maintenance Costs

Integrated DBB valves reduce the need for multiple valve installations, minimizing potential leakage points and decreasing maintenance requirements.

4. Improved Efficiency

Compact DBB valves streamline system design, reducing weight and space requirements while maintaining optimal performance.

Selection Criteria for DBB Valves

Choosing the right DBB valve requires careful consideration of several factors:

Material Compatibility: Selecting materials like stainless steel, carbon steel, or exotic alloys ensures durability and resistance to corrosive environments.

Pressure Rating: Ensuring the valve meets industry-specific pressure requirements is crucial for operational safety.

Design Standards: Compliance with ASME, API, or other international standards guarantees reliability and industry acceptance.

End Connections: Options such as flanged, threaded, or welded connections should match the existing piping system for seamless integration.

Conclusion

Double Block and Bleed valves are indispensable in industries where fluid isolation and system integrity are critical. Their ability to prevent leaks, enhance safety, and reduce operational costs makes them a preferred choice for many applications. Whether in oil & gas, power plants, or water treatment facilities, DBB valves play a crucial role in maintaining efficiency and security.

Freture Techno Pvt. Ltd. is a leading DBB Valves manufacturer in India, offering high-quality, reliable, and durable solutions for various industrial needs.