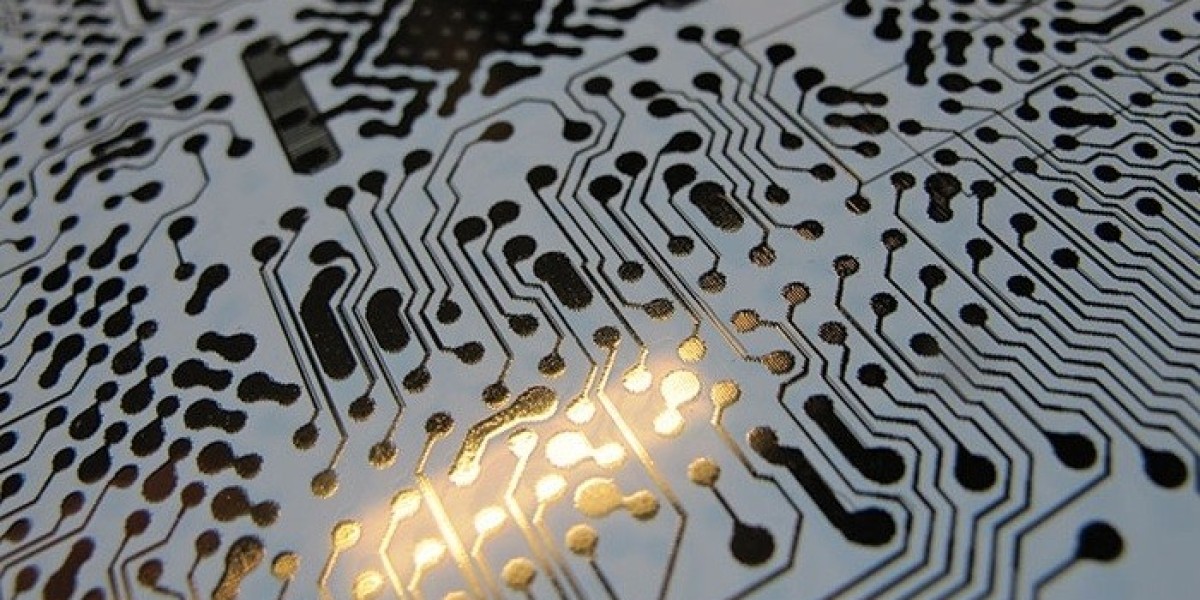

The conductive inks market has emerged as a pivotal sector within the field of printed electronics. These inks are used to create electrical pathways on flexible and lightweight substrates, supporting the growth of numerous industries including consumer electronics, automotive, healthcare, and renewable energy. As the demand for low-cost, efficient, and flexible electronic components grows, conductive inks are becoming increasingly important for manufacturers looking to integrate advanced functionalities into their products. This article delves into the market dynamics, trends, and future projections shaping the conductive inks industry.

Market Trends and Insights

- Increase in Printed Electronics Demand: The rise of flexible electronics has spurred demand for conductive inks, particularly in applications like printed circuit boards, sensors, and displays. This trend is driven by the need for more adaptable and compact devices that can be used in a wide range of consumer electronics and IoT products.

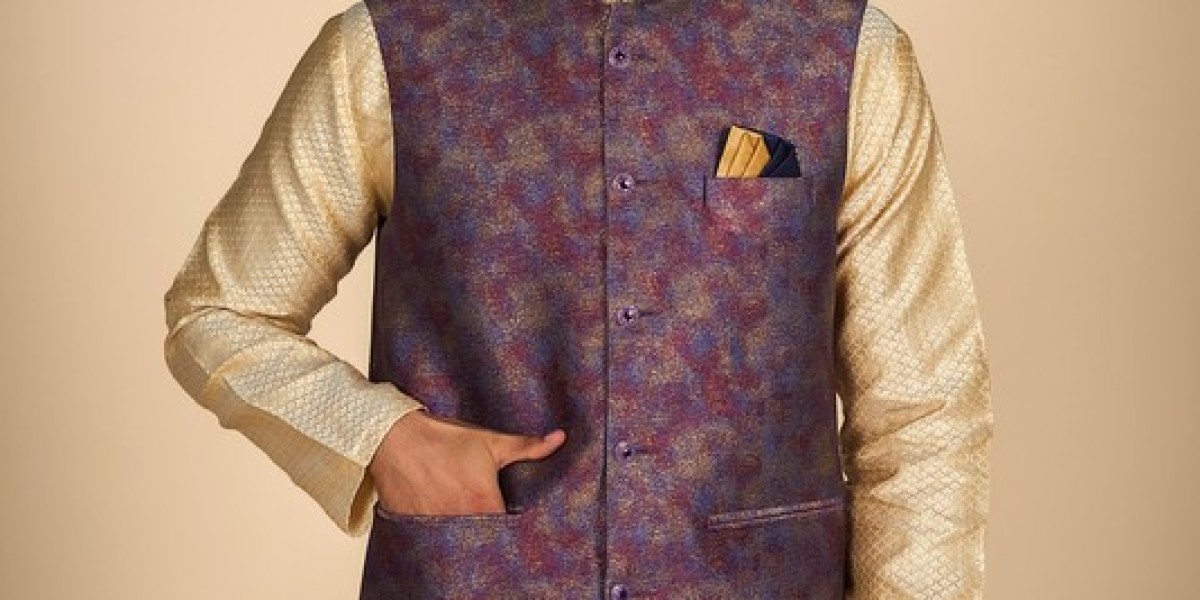

- Growing Wearables Market: The expansion of the wearables market has been a major driver for the conductive inks market, as these devices require flexible and lightweight materials for functionality and comfort. Printed conductive inks provide a cost-effective solution for manufacturers of smartwatches, fitness trackers, and health-monitoring devices.

- Focus on Sustainability: Environmental concerns have prompted a shift toward more sustainable conductive ink materials. Manufacturers are increasingly investing in eco-friendly alternatives to silver-based inks, such as carbon-based or graphene-based inks, which not only offer better performance but also reduce the environmental impact of production.

Key Drivers of Market Growth

- Advancements in Printing Technology: The development of advanced printing technologies, such as inkjet and screen printing, has made it easier and more affordable to produce printed electronics. These methods enable manufacturers to create complex electronic components with high precision while reducing material waste.

- Adoption of IoT and Smart Devices: The rapid growth of the Internet of Things (IoT) and the increasing demand for smart devices have played a significant role in boosting the conductive inks market. As IoT devices require lightweight, flexible, and cost-efficient electrical components, conductive inks offer a viable solution for creating printed circuits and sensors.

- Cost-effectiveness of Printed Electronics: Conductive inks provide a more affordable alternative to traditional manufacturing methods for electronics. This cost advantage is particularly significant in industries like automotive and healthcare, where the demand for flexible, customizable, and mass-produced components is increasing.

Challenges Faced by the Conductive Inks Market

- Material Limitations and High Costs: While silver-based conductive inks are widely used due to their excellent conductivity, the high cost of silver has led manufacturers to seek more affordable alternatives. Materials like copper and graphene are being explored, but these alternatives may still fall short of the conductivity offered by silver-based inks.

- Durability Concerns: The durability and long-term stability of conductive inks, especially in flexible electronics, remain a challenge. These inks must be able to withstand harsh environmental conditions and mechanical stress while maintaining consistent conductivity. Research into improving the durability of conductive inks is ongoing.

- Regulatory and Compliance Issues: The conductive inks market is subject to various regulations, particularly regarding the use of hazardous materials. Manufacturers must ensure that their products comply with local and international standards for safety and environmental impact.

Market Segmentation and Opportunities

- By Application: The conductive inks market is segmented based on application, with key areas including printed electronics, solar cells, sensors, RFID tags, and flexible displays. Among these, printed electronics are expected to dominate, driven by the increasing demand for wearable devices, consumer electronics, and automotive components.

- By Region: The Asia-Pacific region is anticipated to lead the market due to the strong manufacturing base in countries like China, Japan, and South Korea. The region is a hub for the production of flexible electronics and has a rapidly growing consumer electronics industry. North America and Europe are also experiencing significant growth due to advancements in wearable technology and renewable energy applications.

Future Projections for the Conductive Inks Market

- Market Expansion and Innovation: The conductive inks market is expected to experience steady growth over the next decade, with an estimated compound annual growth rate (CAGR) of 20% from 2025 to 2035. This growth is attributed to the increasing adoption of flexible electronics, the proliferation of smart devices, and ongoing advancements in ink formulations.

- Technological Advancements: Research into new conductive ink materials, such as graphene and carbon nanotubes, is likely to play a key role in shaping the future of the market. These materials offer enhanced properties, including lower production costs and improved environmental sustainability.

- Collaborations and Partnerships: Industry leaders in the conductive inks sector are forming strategic collaborations to accelerate innovation and meet the growing demand for printed electronics. Partnerships between material suppliers, electronics manufacturers, and research institutions are expected to drive advancements in conductive ink technologies.