The electronics adhesives market plays a crucial role in modern electronics manufacturing by offering bonding solutions that enhance product reliability, durability, and performance. As technology advances, the demand for these adhesives has surged, driven by their use in various applications such as printed circuit boards (PCBs), semiconductors, displays, and power devices. This growth has been further fueled by the increasing miniaturization of electronic components, the rise of electric vehicles, and the expanding use of consumer electronics. Electronics adhesives are becoming indispensable to the electronic industry, offering solutions for high-performance, long-lasting bonds.

Market Drivers

- Technological Advancements: Continuous innovation in the electronics industry, particularly in wearable devices, IoT gadgets, and automotive electronics, is significantly increasing the demand for specialized adhesives. Electronics adhesives are evolving to meet the demands of newer technologies that require high-temperature resistance and long-lasting adhesion properties.

- Miniaturization of Devices: As consumer electronics become smaller, thinner, and more compact, there is a growing need for adhesives that provide reliable bonding while maintaining minimal thickness. These adhesives are designed to support smaller components without compromising the device's overall performance.

- Growing Electric Vehicle Market: The rising production of electric vehicles (EVs) is a major factor driving the demand for electronics adhesives. These adhesives are essential for applications in battery modules, sensors, and control units, where they ensure the effective functioning of various components.

- Sustainability and Environmental Concerns: The shift toward environmentally friendly materials is pushing for the development of eco-friendly adhesives. As manufacturers focus on reducing their carbon footprint, eco-conscious adhesives that are non-toxic and recyclable are gaining traction in the electronics adhesives market.

Market Segmentation

- By Type: The electronics adhesives market is segmented into epoxy, silicone, acrylic, polyurethane, and other types. Among these, epoxy-based adhesives are the most widely used due to their excellent mechanical strength, thermal stability, and resistance to harsh chemicals.

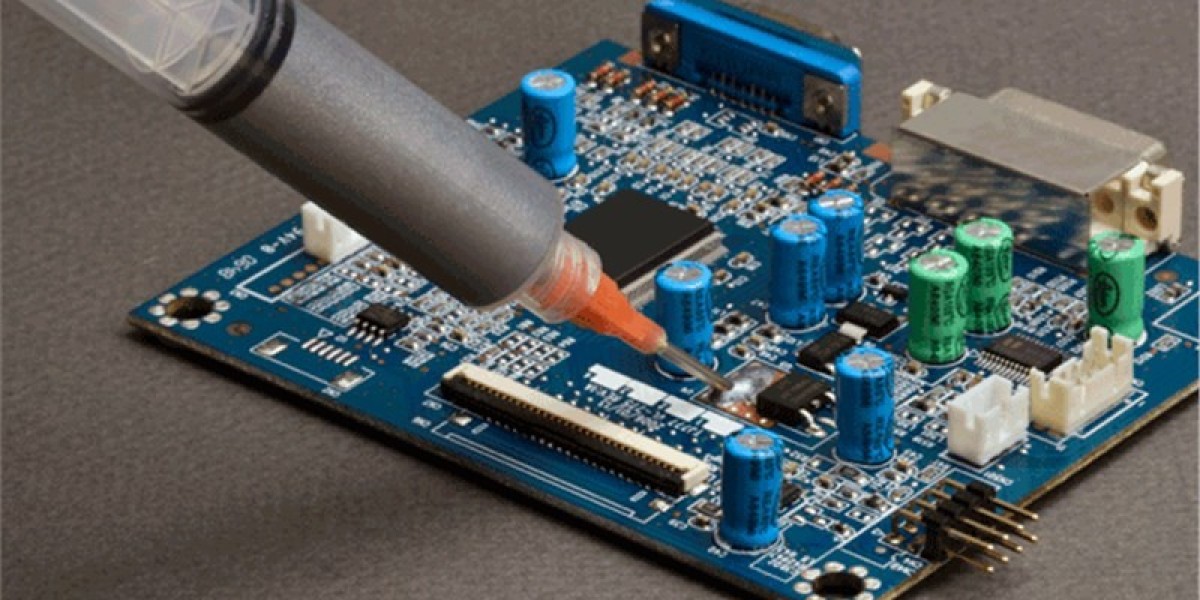

- By Application: Major applications of electronics adhesives include semiconductor packaging, PCB assembly, optical devices, displays, and automotive electronics. PCB assembly, which involves bonding of components to the circuit boards, remains one of the largest applications of electronics adhesives.

- By End-Use Industry: The key end-use industries for electronics adhesives include consumer electronics, automotive, telecommunications, and industrial equipment. With consumer electronics constantly evolving, this industry remains one of the largest contributors to the demand for electronics adhesives.

Key Challenges

- High Cost of Advanced Adhesives: High-performance adhesives, particularly those used in demanding applications like aerospace and automotive industries, come at a higher cost. This presents a challenge for manufacturers, particularly small and medium-sized enterprises (SMEs), that seek cost-effective solutions.

- Regulatory Compliance: Stringent regulations regarding the safety and environmental impact of adhesives are becoming more prevalent. Manufacturers must comply with global regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances), which can increase the complexity of production and lead to higher costs.

- Supply Chain Disruptions: The global supply chain for raw materials used in adhesives is subject to disruption due to geopolitical tensions, natural disasters, or pandemics. This can lead to shortages of key ingredients, such as resins or solvents, affecting the overall production capacity and cost of adhesives.

Regional Insights

- North America: North America holds a significant share of the electronics adhesives market, owing to the presence of leading electronics manufacturers and increased demand from the automotive and consumer electronics sectors. The region's push toward electric vehicles and clean energy is also contributing to the market's expansion.

- Asia Pacific: Asia Pacific is the fastest-growing region, primarily driven by the growing manufacturing capabilities in countries like China, Japan, and South Korea. The increasing demand for smartphones, laptops, and other electronic devices is fueling the market for electronics adhesives in this region.

- Europe: Europe is witnessing steady growth in the electronics adhesives market due to the adoption of advanced technologies in sectors like automotive, industrial equipment, and telecommunications. The push for sustainability and environmentally friendly adhesives is also promoting market growth in this region.

- Latin America and Middle East & Africa: These regions have relatively smaller shares but are expected to witness moderate growth due to the expansion of the consumer electronics market and the rise of industrial applications.

Competitive Landscape

- Key Players: Leading companies in the electronics adhesives market include Henkel AG & Co., 3M, Dow Chemical Company, Huntsman Corporation, and Loctite. These players are focusing on expanding their product portfolios, investing in R&D for innovation, and adopting sustainable practices to maintain a competitive edge.

- Innovation and Mergers: To remain competitive, major players are engaging in strategic partnerships, mergers, and acquisitions to expand their market reach. Additionally, they are investing in innovative solutions to meet the evolving demands of the electronics industry, such as adhesives with improved conductivity and resistance to environmental factors.

Future Outlook

- Smart Technologies and IoT: As the Internet of Things (IoT) and smart technologies continue to grow, the demand for electronics adhesives will likely increase, especially in areas such as smart homes, wearable electronics, and connected devices. These devices require adhesives that offer excellent bonding strength and durability in harsh environments.

- Sustainability: With an increasing emphasis on sustainability, manufacturers will likely focus on producing environmentally friendly adhesives. This includes the development of biodegradable and non-toxic adhesives to align with global environmental regulations.