Leading manufacturers in the automotive heat shield market are adopting strategic approaches to expand their market presence, enhance product innovation, and strengthen global supply chains. These strategies focus on technological advancements, partnerships, geographic expansion, and sustainability initiatives to maintain a competitive edge.

Key Expansion Strategies in the Automotive Heat Shield Market

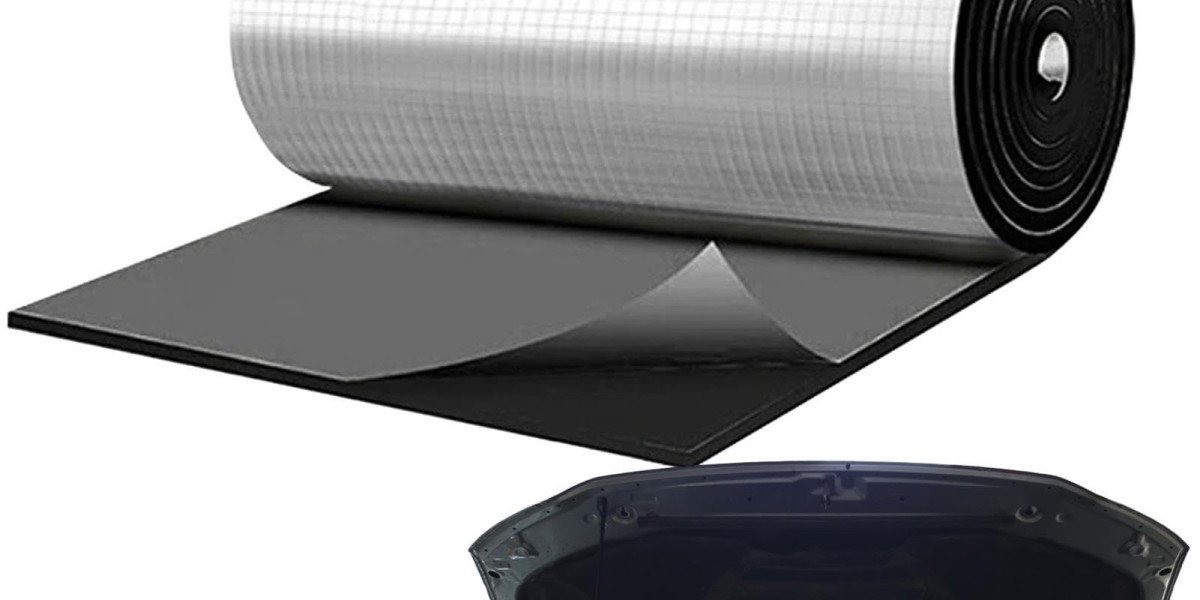

Product Innovation and Advanced Material Development

Manufacturers are investing in research and development (R&D) to develop heat shields with enhanced thermal insulation, lightweight properties, and durability. The integration of advanced materials such as ceramic composites, multi-layer laminates, and high-performance polymers is helping companies meet stringent emission and fuel efficiency standards.

Geographic Expansion and Market Penetration

Leading companies are expanding their manufacturing operations and distribution networks across key automotive hubs, including North America, Europe, and Asia-Pacific. Establishing production facilities in emerging economies such as China, India, and Brazil allows manufacturers to cater to the growing demand for heat shields in passenger and commercial vehicles.

Strategic Partnerships and Collaborations

To enhance product development and market reach, companies are forming strategic alliances with automakers, material suppliers, and technology firms. Collaborations enable faster adoption of innovative heat shield solutions and ensure compliance with evolving industry regulations.

Sustainability and Eco-Friendly Manufacturing

With increasing emphasis on sustainability, manufacturers are focusing on recyclable and lightweight materials to reduce environmental impact. Adopting eco-friendly production processes, such as low-emission coatings and sustainable material sourcing, is becoming a priority for industry leaders.

Integration of Smart Manufacturing and Automation

Automotive heat shield manufacturers are leveraging smart manufacturing technologies, including automation, AI-driven quality control, and digital supply chain management, to enhance production efficiency. The use of Industry 4.0 technologies ensures consistent product quality and cost optimization.

Competitive Landscape and Market Leadership

- Diversification of Product Portfolio: Leading players are expanding their product lines to cater to electric and hybrid vehicles, which require different thermal management solutions compared to internal combustion engine (ICE) vehicles.

- Mergers and Acquisitions (M&A): Companies are acquiring regional players and suppliers to strengthen market position and gain access to innovative technologies.

- Customer-Centric Approach: Customization of heat shields based on automaker specifications and end-user requirements is helping companies gain a competitive advantage.

Final Thoughts

The automotive heat shield market is evolving with technological advancements, regulatory changes, and shifting industry trends. Leading manufacturers are focusing on product innovation, global expansion, and sustainable manufacturing practices to enhance their market presence. Strategic partnerships and investments in smart production techniques will further drive market growth and competitiveness.