3D Printing Automotive Market Definition and Estimation

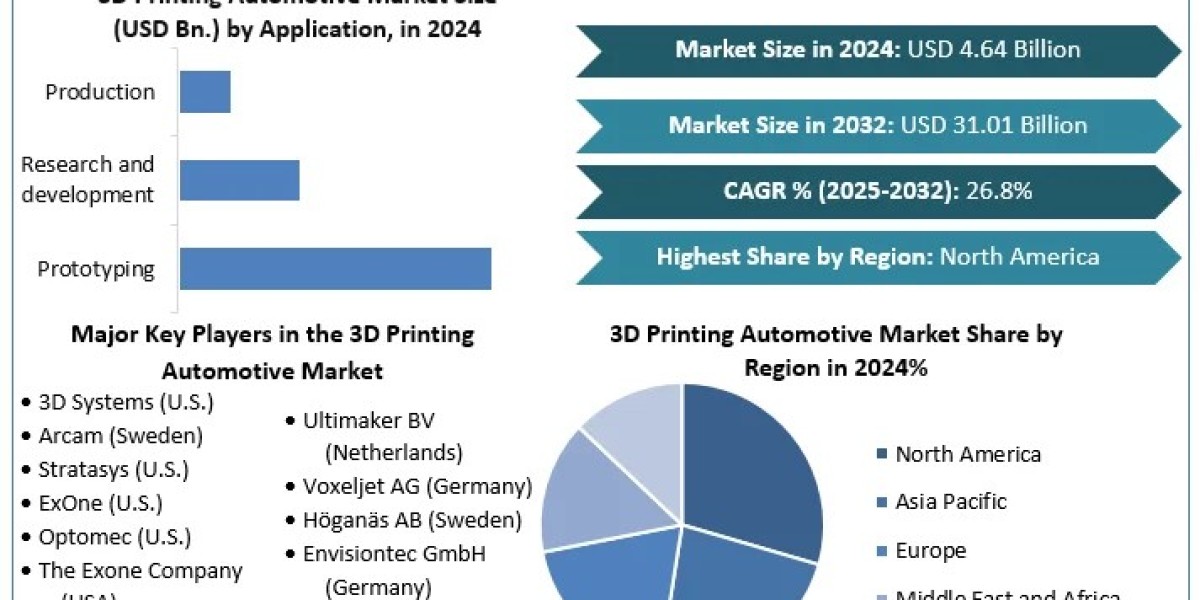

3D Printing Automotive Market Industry, or additive manufacturing, involves creating three-dimensional objects by layering materials based on digital models. In the automotive industry, this technology facilitates the rapid prototyping of components, production of complex parts, and customization, thereby enhancing design flexibility and reducing time-to-market. The market valuation of $4.64 billion in 2024 is anticipated to escalate to $31.01 billion by 2032, driven by the increasing adoption of 3D printing across various automotive applications.

Speak with our Research Analyst:https://www.stellarmr.com/report/req_sample/3D-Printing-Automotive-Market/327

3D Printing Automotive Market Growth Drivers and Opportunities

Several key factors are propelling the growth of the 3D printing automotive market:

Demand for Customization and Personalization: Consumers' growing desire for personalized vehicle features has led manufacturers to adopt 3D printing, enabling the efficient production of customized components without the need for extensive retooling.

Reduction in Production Costs and Time: 3D printing streamlines the manufacturing process by minimizing material waste and reducing the number of required prototypes, leading to cost savings and accelerated product development cycles.

Advancements in Material Science: The development of new materials compatible with 3D printing, including high-strength plastics and metal alloys, has expanded the range of automotive components that can be produced using this technology, enhancing its applicability.

Supply Chain Optimization: By enabling on-demand production, 3D printing reduces the need for large inventories and allows for localized manufacturing, thereby optimizing supply chains and reducing lead times.

Environmental Sustainability: The additive nature of 3D printing results in less material waste compared to traditional subtractive manufacturing methods, aligning with the automotive industry's goals for sustainability and resource efficiency.

Get Free PDF:https://www.stellarmr.com/report/req_sample/3D-Printing-Automotive-Market/327

Segmentation Analysis

The 3D printing automotive market can be segmented based on technology, application, material type, and region:

By Technology:

Stereolithography (SLA): Utilizing photopolymerization to create parts with high precision and smooth surface finishes, SLA is ideal for producing detailed prototypes and intricate components.

Fused Deposition Modeling (FDM): Known for its cost-effectiveness and versatility, FDM is widely used for prototyping and producing functional parts using thermoplastic materials.

Selective Laser Sintering (SLS): Employing laser energy to sinter powdered materials, SLS is suitable for creating durable and complex geometries, making it valuable for functional testing and end-use parts.

Electron Beam Melting (EBM): This technology uses electron beams to melt metal powders, enabling the production of high-strength metal components, particularly beneficial for critical automotive parts.

By Application:

Prototyping and Tooling: 3D printing accelerates the development of prototypes and manufacturing tools, allowing for rapid design iterations and reduced development timelines.

Production of End-Use Parts: The technology facilitates the manufacturing of final automotive components, including complex geometries and lightweight structures, enhancing vehicle performance and efficiency.

Research and Development: Automotive companies leverage 3D printing for R&D purposes, experimenting with new designs and materials to innovate and improve products.

By Material Type:

Plastics and Polymers: Materials such as ABS, PLA, and photopolymers are commonly used for prototyping and producing non-structural components due to their versatility and ease of printing.

Metals and Alloys: Metals like aluminum, titanium, and stainless steel are utilized for manufacturing structural and high-performance parts, offering strength and durability.

Composites: The integration of fibers into base materials results in composites with enhanced mechanical properties, suitable for specialized automotive applications.

More Information About This Research Please Visit @https://www.stellarmr.com/report/3D-Printing-Automotive-Market/327

Regional Analysis

North America:

The region is witnessing significant adoption of 3D printing in the automotive sector, driven by technological advancements and the presence of major automotive manufacturers. The focus on innovation and early adoption of new technologies positions North America as a key market for growth.

Europe:

Europe's strong emphasis on sustainability and advanced manufacturing practices has led to the integration of 3D printing in automotive production. Countries like Germany and the UK are at the forefront, leveraging additive manufacturing to enhance efficiency and reduce environmental impact.

Asia-Pacific:

The rapid expansion of the automotive industry in countries such as China and India, coupled with increasing investments in advanced manufacturing technologies, is propelling the adoption of 3D printing in the region. The focus on mass production and cost efficiency presents significant growth opportunities.

Competitive Landscape

The 3D printing automotive market is characterized by the presence of several key players striving to innovate and capture market share:

Stratasys Ltd.: A leader in additive manufacturing, offering a range of 3D printing solutions tailored for automotive applications, including prototyping and production parts.

3D Systems Corporation: Providing comprehensive 3D printing services and equipment, 3D Systems caters to various automotive needs, from design validation to end-use component production.

Materialise NV: Specializing in software solutions and 3D printing services, Materialise collaborates with automotive manufacturers to integrate additive manufacturing into their production processes.

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud, Pune,

Pune, Maharashtra, 411029