HeatMaster outdoor boilers are some of the most effective and economical heating solutions on the market today. These boilers are built for the long haul, capable of supplying comfort in homes and businesses, as well as keeping farms and workshops warm and comfortable. But, like any other heating system, regular maintenance must be carried out to keep it running efficiently.

It means that doing nothing means higher fuel consumption, uneven heating distribution, and expensive repair bills in the long run. Regular efficiency checks according to an organized maintenance plan and use of high-quality replacement parts would ensure that the outdoor boiler runs without any hitches for a long time.

In this article, we’ll going to explain everything you need to know related to HeatMaster boiler maintenance, including:

- Why regular maintenance is necessary

- Some of the issues that affect boiler efficiency

- Step-by-step maintenance procedures

- Key replacement parts and supplies required

- Where to find good HeatMaster boiler parts and accessories

From this, you will learn how to maximize the life of your boiler, minimize fuel consumption, and prevent costly breakdowns.

Why Regular Maintenance is Crucial for Your HeatMaster Boiler

The outdoor furnace burns firewood, coal, pellet, or any biomass for heating water that subsequently is carried off through insulated underground pipes to your Home, Shop, or business. This would bring comfort and warm even heating and not use fossil fuels such as propane or natural gas at all.

However, if your boiler isn’t maintained properly, several problems can arise:

- Heat loss - ash and creosote buildup in the firebox and heat exchanger reduces heat transfer efficiency, causing the boiler to burn extra fuel to produce the same warmth.

- Clogged Circulation System- get clogged over time due to the mineral deposits and sludge accumulating inside the water circulation system with varying degrees of impeding the pipes and reducing flow. This leads to uneven heating or total breakdown of the system.

- Component Wear and Tear- can occur in component parts, such as pumps, gaskets, seals, and heat exchangers, over time. If these are not evaluated and replaced whenever necessary, they could also lead to leaks, inefficiencies, and potentially dangerous pressure build-up.

- Increased Fuel Costs- This increase in boiler maintenance will cost more in fuel, as an inefficient boiler burns wood or coal far more than it needs to, resulting in higher fuel costs and more frequent refueling.

- Risk of Corrosion- Without proper water treatment, the boiler may get rust and corrode from within, leading to repair costs or complete system failure.

Regular maintenance as discussed in this article, can prevent all these issues by improving fuel efficiency, or extending the life of your boiler. Now let's look at what exactly needs to be done for the Health Master to work at its best.

Essential Maintenance Tips for Your HeatMaster Boiler

Clean the Firebox and Heat Exchanger Regularly

Keeping the firebox and heat exchanger clean is one of the vital steps in operating an outdoor boiler efficiently. Ash, soot, and creosote build up in the firebox steadily with time. This build up reduces heat transfer and makes it harder for the boiler to attain optimum temperature. It also adds significantly to the chimney fire danger.

How often? – The firebox should be checked and cleaned at least once a week under heavy use.

What tools to use? – A wire brush, scraper, and ash vacuum are excellent for removing buildup.

Pro Tip: Do clean the heat exchanger tubes! Blocked tubes mean poor heat transfer; therefore, your boiler burns more fuel to produce equal heat.

Shop high-quality heat exchangers here.

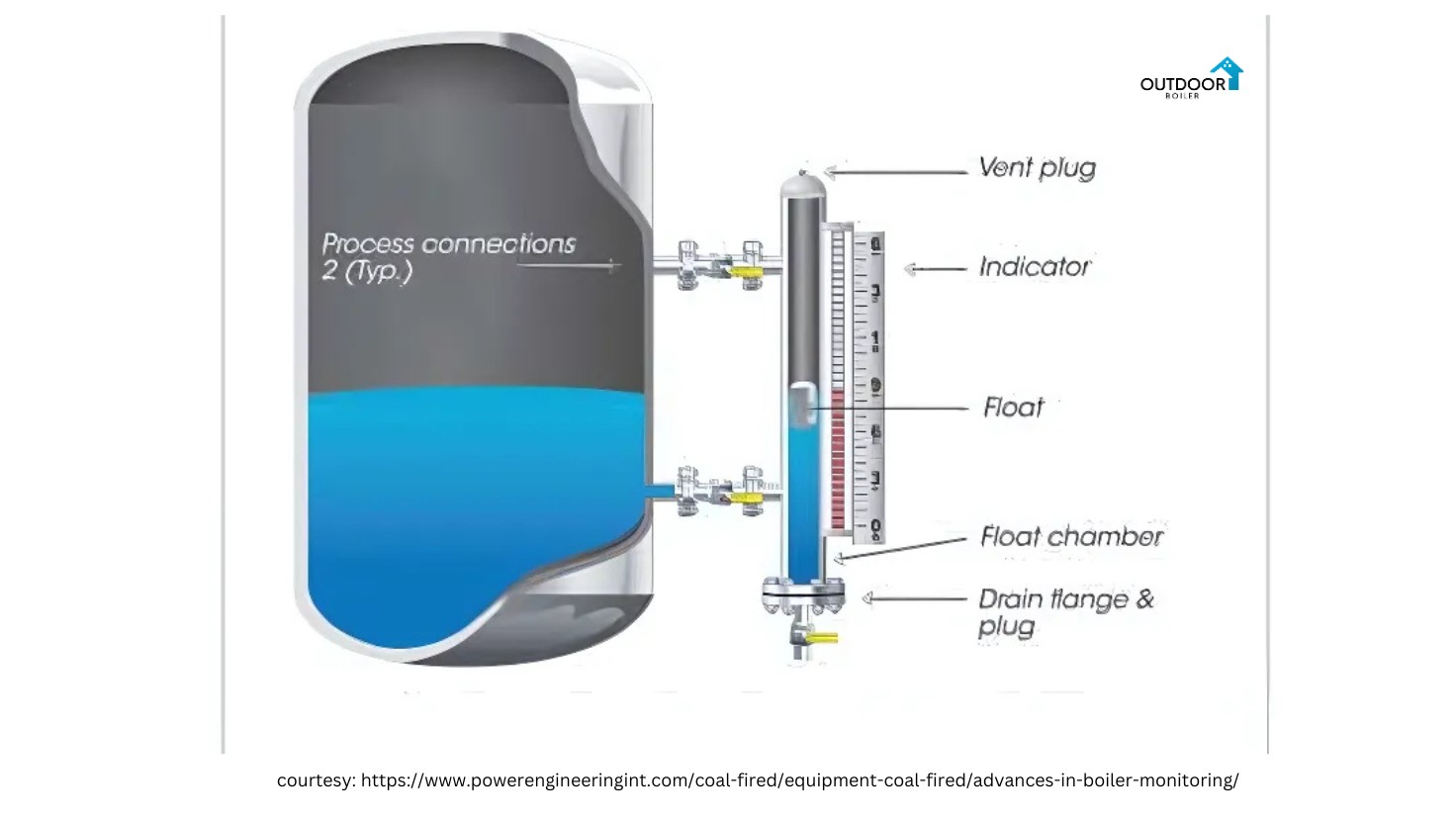

Monitor Water Levels and Pressure

The HeatMaster boiler you own depends on a steady supply of water for its operation. Too little water and the boiler will overheat; too much water and pressure will increase the stress on the components, which means eventual leaks.

How often? Water level should be checked weekly and filled as needed.

How do I set pressure? If pressure happens to be too low or high, consult your owner's manual for the required range and set it accordingly.

Need help? The Outdoor Boiler team can walk you through diagnosing the issues with water pressure.

Test and Replace Water Treatment Chemicals

Using proper water treatment chemicals in any system prevents corrosion, rust and mineral deposition.

Water Treatment: Why? Hard and mineral-rich waters tend to cause scaling problems leading to reduced output and damage to internal boiler components.

How often must I test? Monthly water testing and treatment as necessary.

You can get the best boiler water treatment supplies here.

Inspect and Replace Pumps When Needed

Circulating Pumps transport hot water heated by the boiler to your home. The failure of a pump may lead to uneven heating, more consumption of fuel, and system break down.

Signs of a failing pump:

- Unusual noises or vibrations

- Slow heat distribution

- Leaks around pump fittings

How often do you check your pumps? - Monthly inspection for signs of trouble areas of the pumps.

Need a replacement? – Shop high-quality boiler pumps here.

Use High-Quality Underground Insulated Pipe

Your underground piping system brings heat from your outdoor boiler to your home. If the insulation is inadequate in your pipes, heat may escape into the ground and cause your boiler to work harder than necessary.

What to look for in a good underground insulated pipe?

- Insulation with High R-values for the retention of heat without worries

- Construction that is robust and leak-proof

- Durable materials that are immune to moisture damage

Need new piping? – Discover topmost rated underground insulated pipes here.

Check Door Seals and Gaskets for Leaks

A worn or damaged door gasket can cause air leaks and result in inefficient fuel burning by your boiler.

How to check? Examine the door seal visually for cracks, gaps, or any visible leaks.

How to replace it? Just pull out the old gasket, clean the surface, and install a new one.

Where to buy? Good quality replacement gaskets and seals can be purchased here.

Conclusion

HeatMaster outdoor boiler maintenance is not just about keeping it in a working state; it's maximizing all levels of efficiency, longevity, and savings keys. At some point very soon, a fairly expensive breakdown will occur with that boiler if it doesn't go through regular maintenance.

Replacement parts worn out will improve efficiency and extend the life of the entire system. The good supply will make the investment worthwhile when it is apparent that your boiler is working at its peak efficiency.

At Outdoorboiler.com, we offer you very high-quality boiler parts, pumps, the water treatment supply, insulated pipes, and just about everything you need to support your HeatMaster boiler for many years.

Whether you want help with choosing the right part or not, our crew is ready to provide expert recommendations. For assistance, visit our contact page.

Frequently Asked Questions

1. How important is boiler maintenance?

Boiler failure can mean costly repairs, downtime, and even loss of lives. To prevent boiler failure, one should always have regular maintenance practices in place for the safe and efficient function of the boiler system.

2. Do boilers require more maintenance than furnaces?

The maintenance of boiler units is minimal; generally, annual service tuning by a professional is required. In contrast, furnaces must be inspected every year as well as have their air filters changed every month or quarter.

3. How do you maintain an outdoor wood boiler?

Regularly clean up ash accumulation, keep the water level high, apply a water treatment product, frequently clean the filter, check creosote build-up, and conduct an annual sediment flush. However, remember to read the instructions that come along with your specific type of boiler, and take into consideration a ' dry burn' method for your unit to increase its lifespan.

4. What happens if the boiler isn't serviced?

Over time, boilers can develop problems such as gas leaks, carbon monoxide poisoning, or internal malfunctions that may pose safety concerns. Unless serviced regularly to check for such issues, these problems may go unnoticed until they become serious hazards threatening the occupants' health and safety.

5. Is it worth getting boiler serviced every year?

For the sake of one's boiler, getting it serviced by a professional heating engineer on a yearly basis is the best option. The engineer will be able to observe the appliance and ensure that it's being effectively utilized.