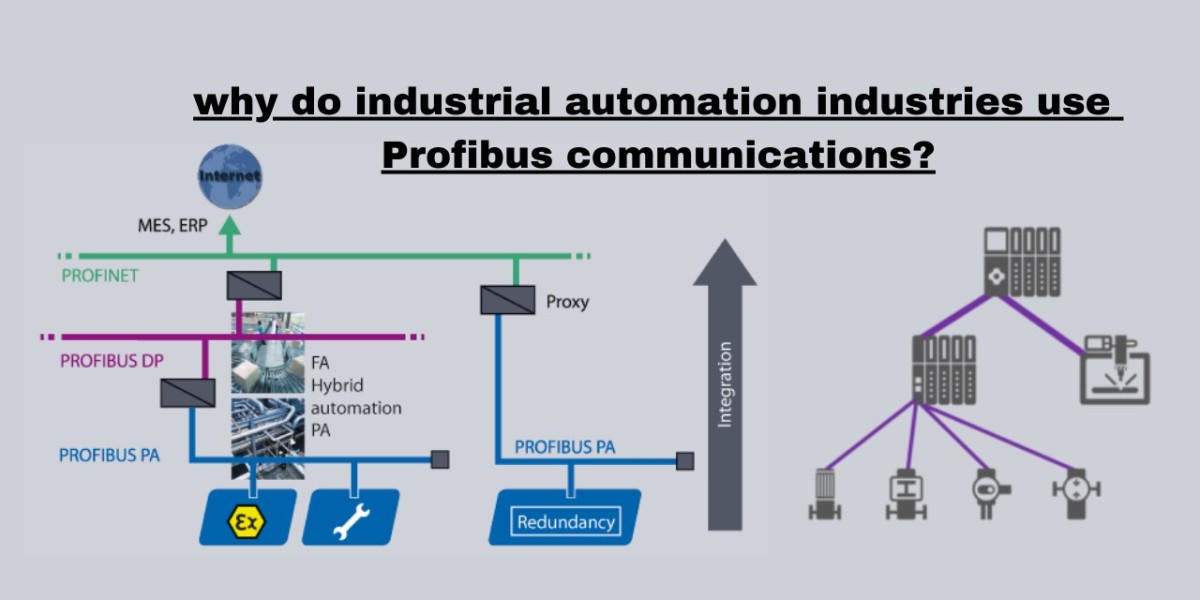

Let me explain why Profibus communication is used by the industrial automation sectors for a variety of reasons, including:

Excessive Velocity and Reliability:

A speedy and reliable communication system called Profibus makes it possible to send information quickly and efficiently across great distances. Because it uses advanced mistake detection and repair techniques to ensure that information is transmitted accurately and dependably.

Compatibility:

In the automation industry, Profibus is widely used, and many devices and processes are created to be compatible with the protocol. As a result, incorporating new components and processes into existing automation networks becomes simple.

Flexibility:

Profibus helps a variety of communication modes, together with point-to-point, multicast, and broadcast. Thus it permits units to speak with one another in quite a lot of methods, relying on the precise necessities of the appliance.

Scalability:

Because Profibus is scalable, it can be used in both small- and large-scale automation techniques. On a single network, it can support up to 126 units, and many networks may be coupled together to construct larger systems.

Diagnostics and Upkeep:

Superior diagnostic capabilities provided by Profibus may be used to identify and resolve problems with the automation system. This could decrease downtime and improve the system's reliability. Additionally, Profibus devices frequently incorporate internal maintenance features that can help detect or prevent problems.

In general, Profibus is a well-known and widely used communication protocol in the automation industry, valued for its speed, dependability, compatibility, flexibility, scalability, and diagnostic capabilities.

Why is profibus connector utilized in automation industries?

In addition to being employed in the automation sectors, PROFIBUS is a widely used industrial communication protocol that allows automation equipment to exchange information and instructions across a community. to connect a variety of community members, such as sensors, actuators, controllers, and various topic units, to the PROFIBUS network.

PROFIBUS connectors provide robust and secure connections between devices even in tough industrial settings. They are resistant to muck, shocks, and high temperatures. They are also tough and waterproof. They are therefore well suited for usage in industrial environments, where equipment is frequently subjected to challenging conditions.

Additionally, PROFIBUS connectors provide high-speed data transfer rates, enabling quick and efficient communication between devices. They will also be able to handle enormous amounts of data, which qualifies them for use in sophisticated automation techniques.

In general, enabling units to talk and operate together smoothly through the use of PROFIBUS connections improves effectivity, reduces downtime, and increases productivity in the automation sectors.

Why are VIPA's profibus connections the best choices for the automation industry?

VIPA is the leading manufacturer of business automation products, including PROFIBUS connections. There are a few reasons VIPA's PROFIBUS connections are thought to be the best solution in manufacturing industries:

Prime quality and reliability:

The PROFIBUS connections from VIPA are built using high-quality materials and can withstand the extreme conditions seen in industrial settings. They have a long service life and are incredibly reliable.

Straightforward set up and upkeep:

The ease of installation and maintenance of VIPA's PROFIBUS connections may result in time and cost savings. They are also intended to be plug-and-play, making it simple to include them into existing automation techniques.

Compatibility:

VIPA's PROFIBUS connectors are a versatile solution for diverse industrial needs since they are made to work with a range of automation devices from various manufacturers.

Price-effective:

The VIPA’s PROFIBUS connectors are reasonably priced. They are therefore a reasonable option for manufacturers that wish to connect a number of units of their automation systems.

Trade experience:

VIPA has extensive knowledge of the industrial automation sector and a thorough grasp of the requirements and difficulties faced by the manufacturing sector. As a result, they are able to develop and produce PROFIBUS connections that precisely satisfy the requirements of manufacturing applications.

In general, VIPA's PROFIBUS connectors provide industrial sectors a high-quality, durable, and affordable solution for connecting automation equipment. This might aid in boosting effectiveness, productivity, and profitability.

Conclusion:

Although Profibus is extensively used, it's important to note that newer technologies have arisen, like Profinet (a Profibus-based Ethernet successor), which offers even faster speeds, more flexibility, and connection with IT networks. The decision between Profibus and newer protocols is influenced by things including the organization's overall technological strategy, application needs, and existing infrastructure.

If you are looking for Rockwell Automation PowerFlex 40 AC drive supplier for your manufacturing industry system, then be sure to choose Asteam Techno Solutions Pvt. Ltd. for best automation solutions. Asteam Techno Solutions Pvt. Ltd. was established in 2017 with a perspective to become a single-source supplier in Automation industry and is now regarded as one of the top Industrial Automation Parts Suppliers in India. We offer you the best products such as HMI, PLC, Power Supply, Servo Motor etc. that we sourced from the trusted brands like Allen Bradley, Siemens, Phoenix Contact, Moxa, Vipa and many more, which give you the maximum possible outcomes.