In today's fast-paced world, engineering plastics have emerged as a vital component of various industries, revolutionizing product design and manufacturing processes. These versatile materials offer an array of properties that make them indispensable in sectors ranging from automotive and electronics to aerospace and medical devices. This blog delves into the key aspects of the Engineering Plastic Market, shedding light on its growth drivers, applications, challenges, and prospects.

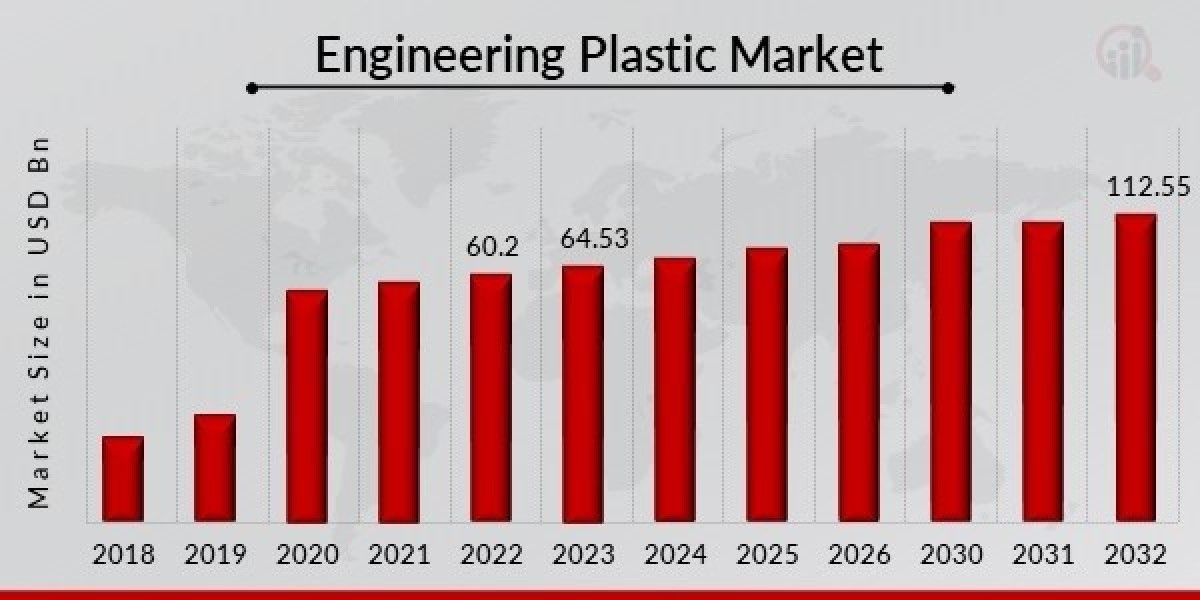

The Engineering Plastic Market was valued at $ 64.5344 billion in 2023, and is projected to reach $ 112.5510522 billion by 2030, growing at a CAGR of 7.20% from 2023 to 2032

Growth Drivers

The engineering plastic market's growth can be attributed to several key drivers. First and foremost is the demand for lightweight and high-performance materials in industries like automotive and aerospace. Engineering plastics, known for their impressive strength-to-weight ratios, are replacing traditional metals, enabling manufacturers to design fuel-efficient vehicles and aircraft.

Moreover, the growing trend towards miniaturization in electronics has boosted the demand for engineering plastics with excellent electrical and thermal properties. These materials provide superior insulation and heat dissipation capabilities, making them essential for applications such as smartphone components, circuit boards, and connectors.

Applications Across Industries

Engineering plastics find application across a diverse range of industries:

Automotive: From lightweight bumpers and interior components to under-the-hood parts, engineering plastics enhance vehicle performance and fuel efficiency.

Electronics: The demand for compact and efficient electronic devices has driven the use of engineering plastics in connectors, housings, and insulating components.

Aerospace: In aircraft interiors and components, engineering plastics offer weight reduction, durability, and resistance to harsh environmental conditions.

Medical Devices: Engineering plastics play a pivotal role in medical devices due to their biocompatibility, sterilizability, and ability to withstand medical-grade disinfectants.

Challenges and Sustainability Concerns

While engineering plastics offer numerous benefits, the market also faces challenges. One significant challenge is related to sustainability. Many engineering plastics are derived from petrochemical sources, raising concerns about their environmental impact. The industry is gradually shifting towards bio-based and recycled engineering plastics to address these concerns and reduce the carbon footprint.

Another challenge is the need to balance cost-effectiveness with performance. Engineering plastics can sometimes be more expensive than traditional materials, impacting their widespread adoption. Manufacturers must carefully consider the overall lifecycle cost and benefits of using these materials.

Prospects

The engineering plastic market's future looks promising, driven by ongoing research and innovation. As technology advances, new formulations of engineering plastics are being developed, offering enhanced properties such as improved heat resistance, flame retardancy, and chemical stability. 3D printing and additive manufacturing are also opening new avenues, allowing for the creation of complex shapes and customized parts using engineering plastics.

Furthermore, the push towards a circular economy is encouraging the adoption of recycling technologies, which can help alleviate the environmental impact of plastic waste. Recycled engineering plastics are finding applications in various industries, contributing to both sustainability and resource efficiency.

Conclusion

The engineering plastic market has revolutionized modern industries by providing materials that combine exceptional mechanical properties with design flexibility. The growth of this market is fueled by the need for lightweight, durable, and high-performance materials across sectors such as automotive, electronics, aerospace, and medical devices. Despite challenges related to sustainability and cost, ongoing research and innovation are driving the development of new formulations and applications. As the world moves towards a more sustainable future, engineering plastics are poised to play a crucial role in shaping innovative solutions for a wide range of industries.

About Market Research Future:

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis about diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing the optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: sales@marketresearchfuture.com

Website: https://www.marketresearchfuture.com