Hey there, welcome to Metal Magic! Metal fabrication options are the best when it comes to coming up with new ideas and solving problems. For accurate cutting, dependable welding, or custom machine shop services, Hamilton, Ontario is the place to go. It's a center for all things metal manufacturing. This blog post will show you the advantages of using metal production solutions and show you examples of how well they've worked in real life. Hold on tight for a sneak peek at what the future holds for this constantly changing business. As we dive into the world of Metal Fabrication Hamilton Ontario, get ready to be amazed by the amazing things that can be made from metal!

Why using metal fabrication solutions is a good idea

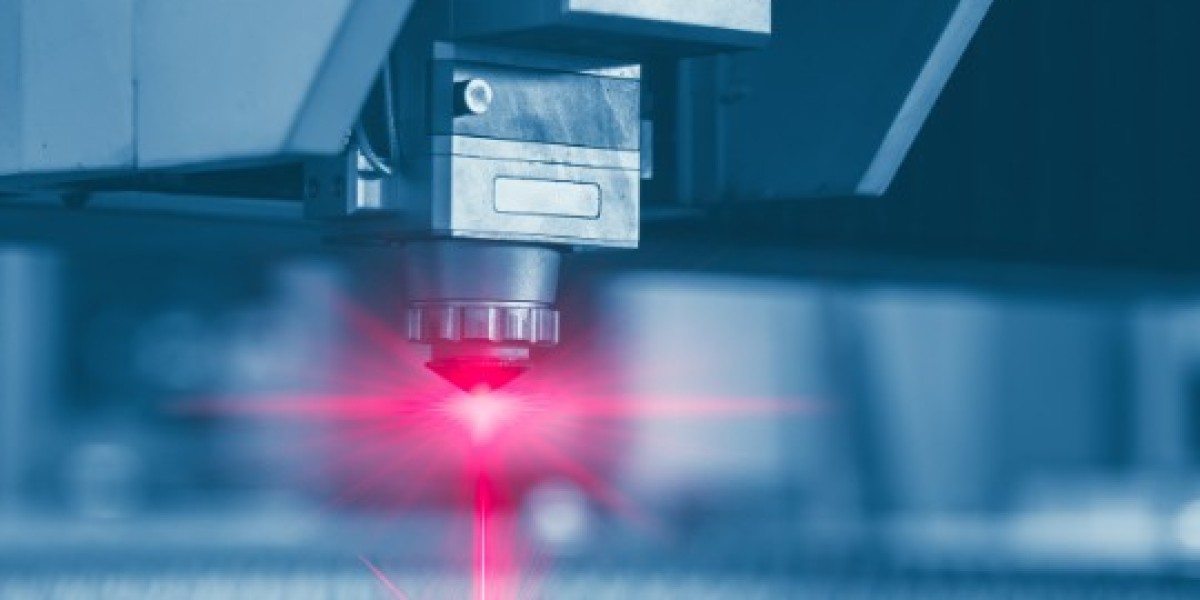

With metal fabrication solutions, there are a lot of different perks. One big plus is precision. With cutting-edge tools like aluminum laser cutting in Hamilton, Ontario, you can make designs and forms that are very complicated very accurately.

Metal manufacturing is known for being flexible. Metal fabrication is very flexible and can easily meet the needs of many different businesses, from those that make parts for cars to those that build buildings. In Hamilton, machine shops can make products that are unique and fit your needs.

Along with accuracy and flexibility, one of the best things about metal manufacturing is that it lasts a long time. Fabricated metal goods are very strong and don't break easily because they are made with high-quality materials and skilled craftsmanship.

In the field of metal fabrication, speed is also very important. The efficient methods that professionals use make sure that projects are finished on time and to high standards of quality and safety.

Last but not least, when thinking about the benefits of metal fabrication options, you can't forget about how cost-effective they are. Clients can get the results they want while staying within their budgets if they use efficient manufacturing techniques and improved production methods.

In end, I say "Oops!" I'm sorry about that! Don't worry about the findings yet; next we'll look at real-life case studies of successful metal fabrication projects.

Case studies are real-life examples of metal fabrication projects that went well.

Projects are the best way to show that you know how to work with metal. Let's look more closely at some real-life cases that show how powerful and useful this new idea could be.

A company in Hamilton, Ontario, was having trouble in one case study. They needed aluminum parts for their tools that were made just for them because they couldn't find anything that would work. Here comes metal production. With aluminum laser cutting services, they were able to make parts that were precise, fit their needs correctly, and were made just for them.

A machine shop in Hamilton, Ontario, is the subject of another success story. For an industrial job, they had to build complicated structures. With metalworking skills like welding and CNC machining, they were able to take simple materials and make complex parts that fit together perfectly in the end result.

Don't forget about GTA Laser Cutting either! The ability to make accurate cuts and complex designs with this technology has changed the way fabricators work. Think about how easy it would be to make even the hardest ideas come to life.

The things shown in these case studies are just a small part of what metal production solutions can do. This technique is very flexible and can be used by businesses in many different fields. It can help them get around design limits and improve efficiency and accuracy. If you need custom parts or help with difficult jobs, you might want to use the power of metal fabrication. It could actually be your ticket to success!

What the Future Holds for Metal Fabrication

The world of metal fabrication is always changing, and as technology gets better, the options for the future are really exciting. Here are some possible changes that could happen in the future of metal production, ranging from new materials to new ways of doing things.

3D printing is an area that has a lot of potential. Even though metal manufacturing may still be in its early stages, this technology could completely change the field. With just a simple digital drawing, you could easily make metal parts that are very complicated.

Automation and robots could also be used in the process of making metal things. Manufacturers can be more efficient and productive while cutting down on labor costs by using robots and automated tools to do repetitive tasks.

Nanotechnology also opens up interesting possibilities for making things out of metal. Scientists could make metals with better qualities, like more strength or conductivity, by changing materials at the atomic level.

Along with these new technologies, sustainability is going to be very important in the future of metal fabrication. As worries about the environment continue to grow, using recycled materials and using eco-friendly methods during the whole manufacturing process will become more important.

People who work with metal can only guess what the future holds, but one thing is for sure: new ideas will keep pushing this field forward. When it comes to breaking new ground and discovering new ways to make high-quality goods quickly and environmentally friendly, the options are endless.

In conclusion

In this fast-paced world, where speed and new ideas are very important, metal fabrication solutions have become a game-changer. In many different industries, these methods are very useful because they can turn simple materials into complex structures and parts. Putting metal together has been useful for many years, for both small jobs and big industrial uses. The case studies we looked at in this article showed how companies used metal fabrication to their advantage and found success. It seems like there are a lot of options, like making custom parts for automakers or using lightweight alloys to change the aerospace business.

The future looks even brighter for making things out of metal. Precision and speed are always being pushed to the limit by new technologies like metal laser cutting and GTA laser cutting. As the need for environmentally friendly practices grows, metal fabricators are looking into eco-friendly options such as recycling old materials or running their businesses on green energy.

Metal Fabrication Hamilton Ontario is about to play a big part in making our modern world, but they don't say so directly. Businesses that want to find new ways to boost output and growth must use this product because it is flexible, long-lasting, and affordable. If you need a machine shop or welding services in Hamilton, Ontario, GTA Laser Cutting can help you. They have years of experience and are very good at what they do. Enjoy the magic of making things out of metal today!