In the era of Industry 4.0, there is an unsung hero that plays an important role in several procedures - the industrial burner. While commonly ignored, these modest devices attain the potential to shape the very basis of manufacturing and creation.

An industrial burner is equipment made to blend fuel and air in accurate proportions, making a controlled combustion procedure. This controlled burning produces enormous heat energy, which discoveries application in a myriad of industrial procedures. From electrified boilers that generate steam to melting metallic elements in foundries, and even baking bricks in ovens, industrial burners are the unsung designers of uncountable merchandise we use daily.

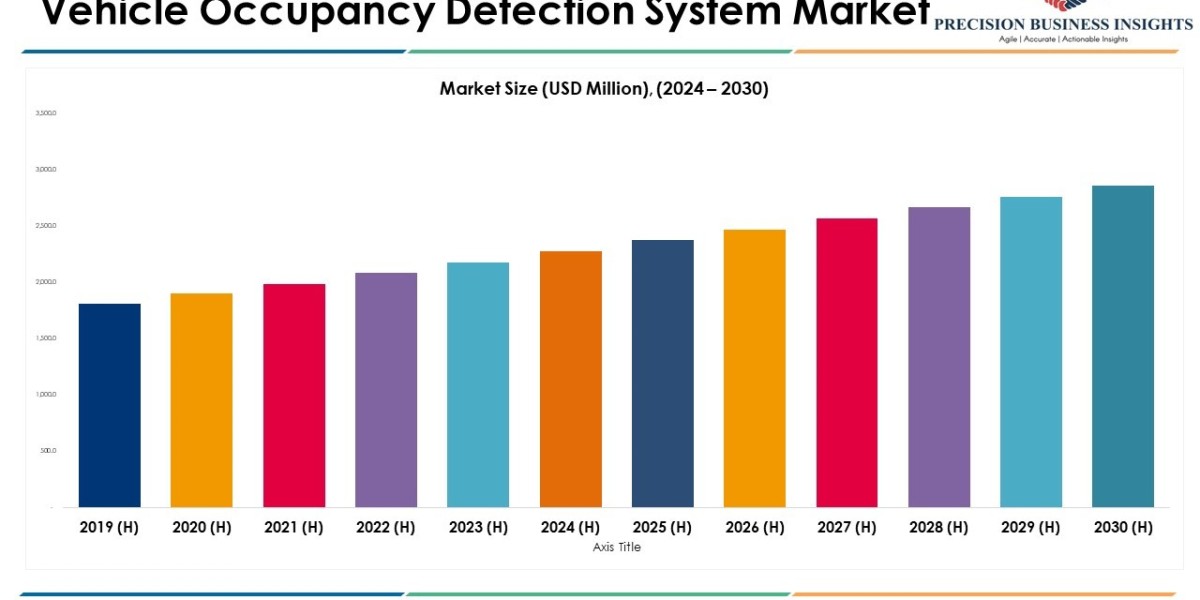

The industrial burner market is experiencing growth and is projected to reach USD 9,501 million by 2030.

The Inner Workings

Behind the scenes, the inner mechanisms of an industrial burner look like a carefully created blend of engineering and science. A main element is the head of the burner, where air and fuel meet. Such components are required to be accurately balanced to guarantee effective combustion, diminishing waste, and making the most of power output.

The fuel itself can differ extensively, fluctuating from natural gas and petrol to biofuels and even waste materials. The option of fuel hinges on reasons like availability, cost, and environmental considerations. Likewise, the design of the burner head, the preparation of flame stabilization, and the supply of heat all contribute to the ideal performance of the burner.

APAC Is the Market Leader

APAC has the leading position in the industrial burner market, and it will hold the same position till 2030, with a value of USD 4,276 million. This is attributed to the growing industrialization; rising petrochemical and mining activities; and governments of several developing countries implementing stringent regulations and various strategies for minimizing carbon emissions. In APAC, the Chinese market holds the leading position, and it will grow at a CAGR of more than 7% during the forecast period. This is attributed to the low cost of land, labor, and raw materials for the development of burners in the country.

Lighting the Path to Innovation

As technology is advancing, the world of industrial burners endures to advance. Pioneering improvements have led to burners with automated adjustments, digital controls, and remote monitoring abilities. Such innovations not only advance working effectiveness but also contribute to enhanced security by lessening human involvement in possibly dangerous environments.

Additionally, the addition of AI and information analytics is making the path for projecting the maintenance of industrial burners. By analyzing performance information, potential problems can be recognized and confronted before they escalate, decreasing downtime and enhancing production.

The Fiery Future Beckons

the role of industrial burners is similar to the concealed brushstrokes that give life to a work of art. Their fiery hold shapes materials, fuels progress, and plays an important part in the making of items that describe our modern lives.

So, next time you appreciate a flawlessly baked loaf of bread, marvel at an exactly molded piece of metal, or just bask in the comfort of a heated room, take a moment to appreciate the unsung hero behind the scenes - the industrial burner.