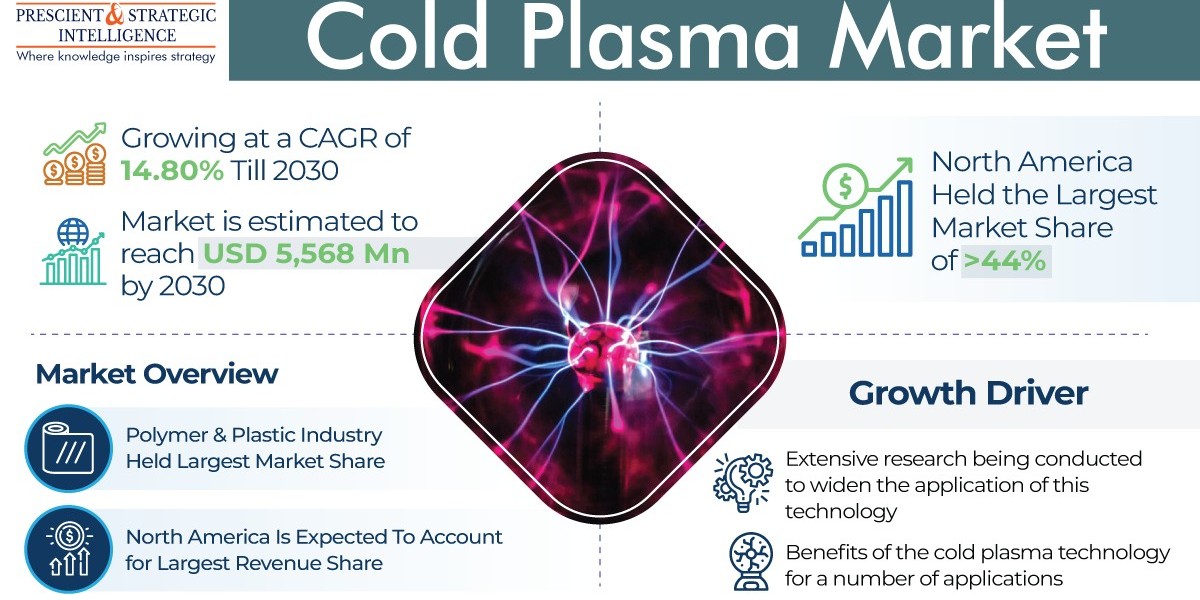

It was stated by P&S Intelligence, the cold plasma market will witness growth at a rate of 14.80% by the end of this decade, touching USD 5,568 million by 2030.

It will be as a result of the benefits of the cold plasma technology for numerous applications, such as healing of wounds, and the progressions in it.

Furthermore, in biomedicine, cold plasma is used for teeth and skin disease treatment and the medical device sterilization. In material sciences, it is put to use for modifications of surfaces, while in the food sector, it is used in packaging, and food production.

Also, in environmental sciences, it is used in the water and air purification.

Atmospheric cold plasma had the larger share of revenue, as a result of its use in a number of applications. For example, it has brought about promising results in the treatment of eczema.

The wound healing category will register the highest CAGR, of 15.4% in terms of revenue by the end of this decade. This is due to the fact that researchers are using cold plasma for speeding up the external wound healing in the current scenario.

North America cold plasma market had the largest share, of 44%, in the past, and will power with a substantial rate in the near future. This is attributable to the upsurge in the healthcare spending and research and development activities.

Furthermore, the federal government has increased its budget for cancer research. The Consolidated Appropriations Act, 2023 has owed USD 7.3 billion to the NCI, which was a USD 408 million surge over the 2022 grant, as well as USD 216 million for the aspects of the Cancer Moonshot program being supervised by the NCI.

The polymer & plastic category dominated the industry with a share, of over 32%, in 2022. This is because of the fact that plastic and polymer use need robust surface adherence for getting the finest mechanical functionality and prolong the life of the plastic components.

Seeing the wide application of this tech in the polymer & plastic sector, more than a few market players have started introducing systems and devices that let this industry to make use of it.

In the preparation and modification of the surface of textiles, plasma treatment has an advantage over the conformist pretreatment and finishing procedures, since the former is done without the use of water and chemicals, some of which are extremely toxic for nature.

This allows cost savings and environment-friendly procedures. Until now, it is used for modification of the outermost surface features of the textile substrate, without making any alterations to the properties.

Because of the various benefits of cold plasma technology all over the world, the demand for cold plasma will continue to rise in the future.