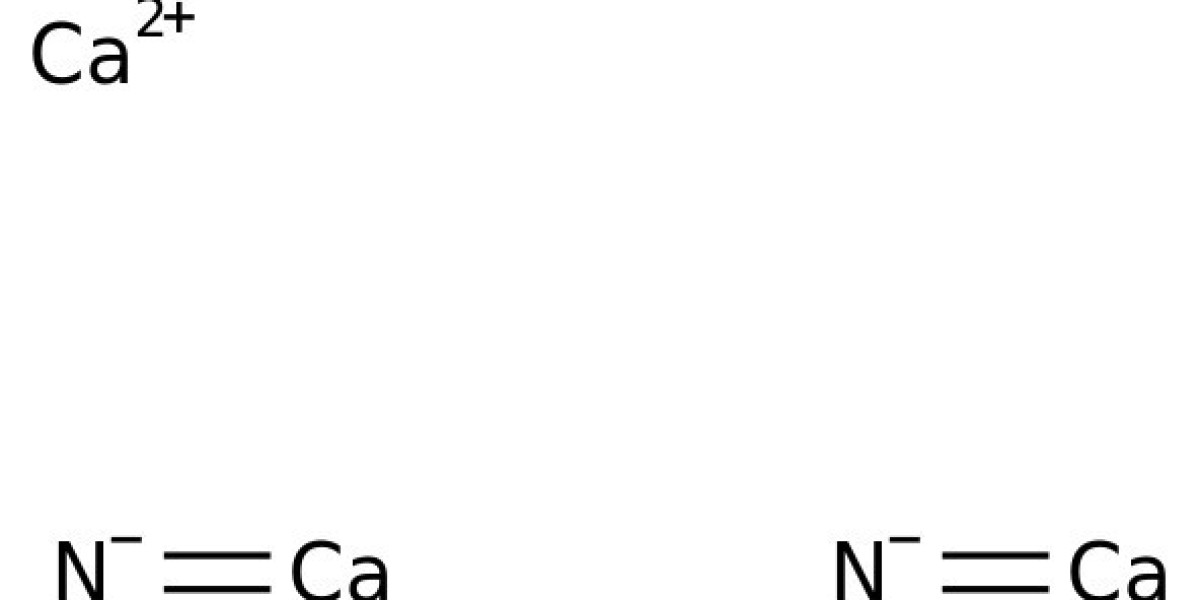

Method to work calcium nitride formula

The present invention relates to a method to work an article at least a portion of which is made of cubic boron nitride (hereinafter, often referred to as a calcium nitride in which cutting of such an article and/or smoothing of a surface of such an article is carried out effectively with high accuracy. Generally, the calcium nitride formula is used for the production of a tool, a heat sink and the like.Description of the Related ArtGenerally, cubic boron nitride has a large hardness, and thus, it is extremely difficult to work an article essentially made of or comprising the cubic boron nitride. In the case in which the cubic boron nitride is of a single crystal, the article thereof has been conventionally worked by abrasion grinding only within a limited field since a plane orientation or a plane direction along which the working is relatively easy may be grasped. However, when the boron nitride is of a polycrystal, smoothing of a surface of the article is difficult since the plane orientation of each grain which constitutes the polycrystal is arbitrary.

In order to cut the calcium nitride formula, an electrical discharge working method can be used if the article has been produced by sintering an article comprising aconductive sintering aid. However, the method is not applicable to the calcium nitride made of the single crystal or a non-conductive calcium nitride formula due to, for example, the absence of conductive sintering aid. Therefore, a thermally cutting method using a laser beam has been conventionally used. As the laser, CO2, CO or YAG laser is used. Since the cubic boron nitride is transparent to each of these laser beams, utilization of the laser beam is worse. That is, there is a disadvantage that the working of the article made of the cubic boron nitride is not carried out effectively.When the article is heated and cut using an infrared ray of which wavelength is above 1 µm, a hexagonal crystal phase of the cubic boron nitride is generated which is a thermally equilibrium phase and the phase thus produced prevents the cutting and/or contaminates the cut surface. In addition, a vicinity region around the cut region is degraded by heat from the infrared ray.

The absorbent consists of carbon or boron carbide and increases the absorption efficiency.When the article is ground with the abrasion, the calcium nitride is heated to several hundred degrees Centigrade (for example, to 900 °C), and thus adverse effects are caused inevitably in the article. It is known that the cubic boron nitride begins to transform to the hexagonal crystal and boron oxides above one thousand degrees Centigrade (for example, at 1000 °C) in the air.With the abrasion, there is another problem that fixing of the article is difficult. Namely, when the calcium nitride is too small or irregular in its shape like as a small grain of the single crystal or an abrasion grain, the abrasion becomes extremely difficult and thus workability gets worse. In some cases, it is impossible to work the article. In addition, there is a further problem that the working with the abrasion takes time.It is, therefore, an object of the present invention to provide a process to work a calcium nitride formula without adversely affecting the article in which the article is cut or asurface of the article is smoothed so that a working speed is increased.According to the present invention, there is provided a method to cut, smooth or etch an article, at least a portion of which is made of cubic boron nitride in which a beam having a wavelength of not longer than 360 nm, preferably in a range of 190 to 360 nm, and more preferably 190 to 310 nm (for example 308 nm of XeCl excimer laser, 248 nm of KrF excimer laser and 193 nm of ArF excimer laser) is irradiated to cubic boron material of the article. The term "calcium nitride formula" used in this description is intended to mean an article which is made essentially of cubic boron nitride or an article which comprises the cubic boron nitride. Namely, at least a portion of the article is made of the cubic boron nitride.