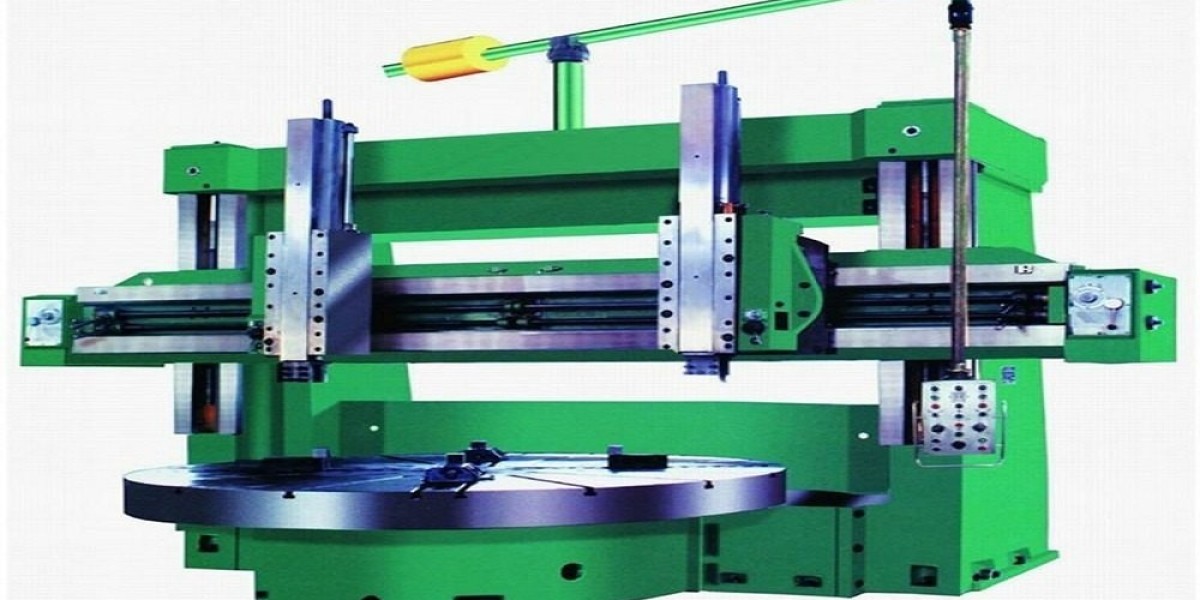

In recent years, the manufacturing landscape in India has undergone a significant transformation with the integration of advanced technologies. One such technological marvel making waves in the industry is the Vertical Turning Lathe Machine. This cutting-edge equipment has revolutionized the way components are manufactured, offering enhanced precision, efficiency, and versatility.

The Genesis of Vertical Turning Lathe Machines

Vertical Turning Lathe Machine in India, commonly known as VTL machines, have a rich history dating back to the industrial revolution. However, the recent surge in their popularity can be attributed to the rapid advancements in engineering and design. These machines are designed to handle large and heavy workpieces, providing a solution to the evolving needs of various industries.

Increased Efficiency and Productivity

In a competitive manufacturing environment, efficiency is key. Vertical Turning Lathe Machines excel in this aspect by significantly reducing machining times. The vertical orientation of the workpiece and the tool's ability to move in multiple axes enable simultaneous machining operations, leading to faster production cycles and increased overall productivity.

Versatility Across Industries

The adaptability of these machines to handle various workpiece sizes and shapes makes them ideal for both small-scale workshops and large-scale manufacturing facilities. This versatility has positioned Horizontal Boring Machines in India as a go-to solution for a broad spectrum of manufacturing needs.

Technological Advancements in Indian Manufacturing

The adoption of Vertical Turning Lathe Machines in India signifies a shift towards embracing cutting-edge technologies in the manufacturing sector. With an increasing focus on automation, artificial intelligence, and Industry 4.0 principles, Indian manufacturers are aligning themselves with global standards to stay competitive on the international stage.

Conclusion:

The advent of Vertical Turning Lathe Machines in India marks a significant milestone in the country's manufacturing journey. With their precision, efficiency, and versatility, these machines are playing a pivotal role in shaping the future of Indian manufacturing. As industries continue to evolve and embrace advanced technologies, End Milling Machine in India stand tall as a symbol of progress and innovation in the realm of machining.