Acrylates are produced by reacting acrylic acid with an alcohol. These esters are primarily used in the production of different types of paints and coatings, plastics, floor polishes, and adhesives. Owing to the exceptional durability, zero concentration of volatile organic compounds (VOCs), and excellent stability at extreme temperatures offered by acrylate-based paints and coatings, their consumption has significantly surged. High-volume usage of such paints and coatings can be credited to the boom in the construction industry, primarily on account of the burgeoning population and accelerating urbanization rate across the world.

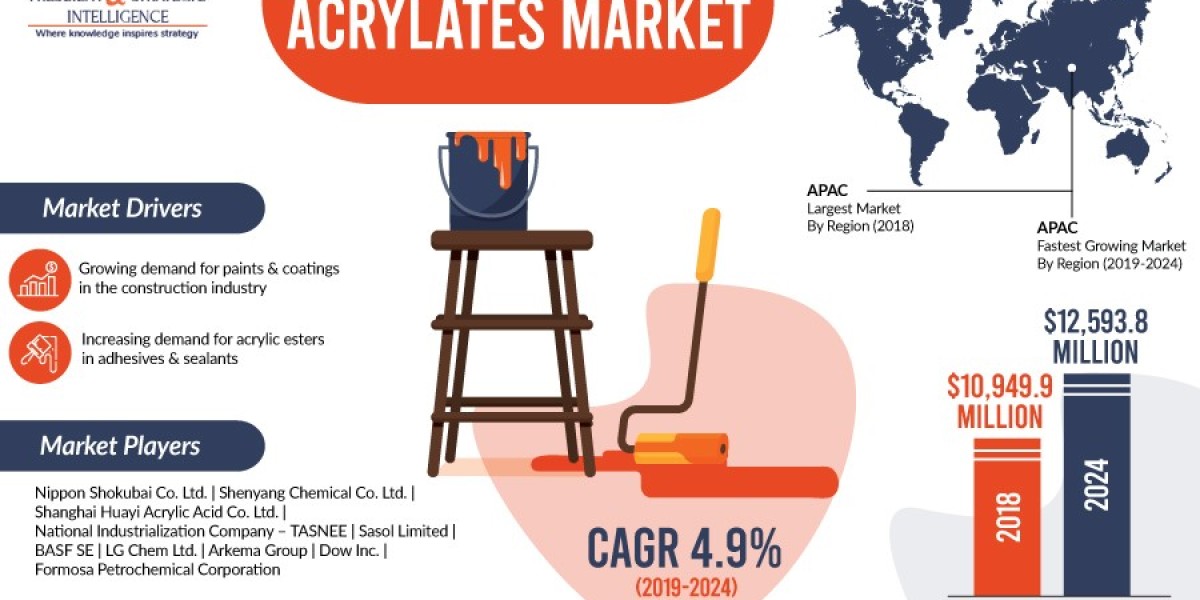

Moreover, the increasing preference for acrylic-based emulsions over oil-based formulations, due to their short drying time, resistance to water and wear, environment-friendliness, and color fastness, will propel the acrylates market at a CAGR of 4.9% during 2019–2024. The market revenue stood at $10,949.9 million in 2018 and it is expected to reach $12,593.8 million revenue by 2024. Additionally, the growing health concerns and rising government regulations regarding oil-based products have fueled the shift toward acrylic emulsions.

Nowadays, acrylate producers such as BASF SE, Jiangsu Sanmu Group, Dow Inc., China National Petroleum Corporation, Arkema Group, Shenyang Chemical Co. Ltd., Formosa Plastics Corporation, China Petroleum & Chemical Corporation, and SunVic Chemical Holdings Ltd. are focusing on collaborations to reach out to more customers. For instance, in January 2018, BASF SE and Adani Group started a joint venture for developing a manufacturing facility in Gujarat, India, with an investment of around $2.2 billion (EUR 2.0 billion). This joint venture will have production units for butyl acrylate, propane dehydrogenation, glacial acrylic acid, and oxo C4 complex.

At present, the manufacturers are focusing on producing butyl acrylate due to its increasing usage in acrylic polymer-based latex paint formulations, owing to its high sunlight resistance and low-temperature stability. Apart from this, manufacturers are also producing methyl acrylate, 2-ethylhexyl acrylate, and ethyl acrylate. These different types of acrylates are used in the manufacturing of adhesives and sealants, acrylic fibers, textile chemicals, paints and coatings, and leather chemicals.

According to P&S Intelligence, Asia-Pacific (APAC) consumed the highest volume of acrylic formulations in the recent past, and it is expected to retain its position as the leading consumer in the coming years too. This can be primarily owed to the presence of established players, high demand for water-based paints and coatings, and surging infrastructure development activities in the region. Among APAC nations, China is expected to consume the highest quantity of acrylates in the foreseeable future, due to the high-volume downstream product manufacturing capabilities of end-use industries in the country.

Moreover, the APAC acrylates market will also exhibit the fastest growth in the coming years, on account of the soaring demand for acrylic products in the automotive and construction industries, due to the increasing urbanization, rising population, and soaring disposable income of people in the regional countries such as Japan, South Korea, India, and China. Moreover, the escalating investments being made in the construction sector in India, South Korea, Japan, and China will also amplify the usage of acrylic-based paint formulations in the region.

SOURCE: P&S Intelligence