IMARC Group, a leading market research company, has recently releases report titled “Mesh Nozzle Plates Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032,” The study provides a detailed analysis of the industry, including the global mesh nozzle plates market share, size, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the mesh nozzle plates market?

The global mesh nozzle plates market size reached US$ 32.2 Million in 2022. Looking forward, IMARC Group expects the market to reach US$ 46.7 Million by 2028, exhibiting a growth rate (CAGR) of 6.51% during 2023-2028.

Factors Affecting the Growth of the Mesh Nozzle Plates Industry:

- Industrial Expansion Across Various Sectors:

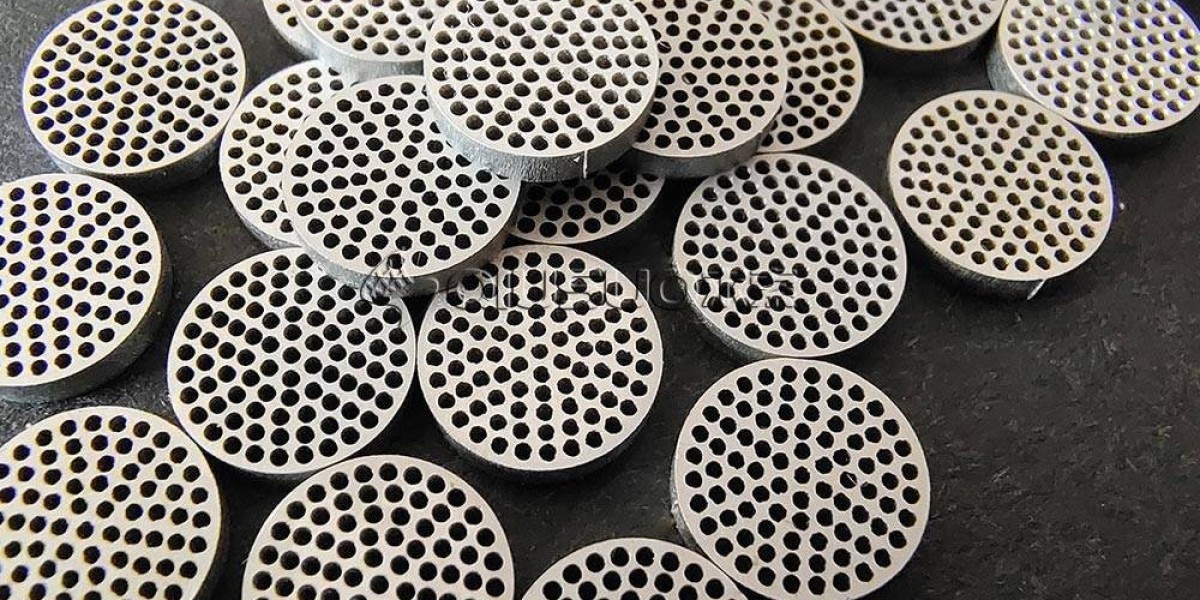

Industrial expansion across sectors such as chemicals, pharmaceuticals, automotive, and food processing is a significant driver of the mesh nozzle plates market. These industries rely on mesh nozzle plates for various critical applications including filtration, spraying, coating, and atomization processes. In the chemical sector, mesh nozzle plates are utilized for precise spraying and coating applications in chemical processing and production. Similarly, in the pharmaceutical industry, these plates are essential for precise drug formulation, coating, and granulation processes. In the automotive sector, mesh nozzle plates are used in painting and coating applications for vehicle manufacturing. Additionally, in the food processing industry, they play a vital role in spraying, coating, and flavoring processes, ensuring product quality and consistency. As industrial activities continue to expand across these sectors, the demand for mesh nozzle plates is expected to grow significantly.

- Technological Advancements and Innovation:

Ongoing advancements in nozzle plate designs, materials, and manufacturing processes are driving innovation in the mesh nozzle plate market. Manufacturers are continually refining nozzle plate designs to enhance performance, durability, and efficiency in various industrial applications. This includes optimizing nozzle geometry, aperture size, and spray patterns to achieve precise and uniform dispersion of fluids. Additionally, advancements in materials science have led to the development of new materials with superior properties such as corrosion resistance, wear resistance, and thermal stability, expanding the range of applications for mesh nozzle plates. Furthermore, improvements in manufacturing processes, such as laser cutting and 3D printing, enable the production of complex nozzle plate designs with high precision and consistency, meeting the evolving needs of industries requiring filtration, spraying, coating, and atomization solutions.

- Regulatory Standards and Environmental Concerns:

Stringent regulatory standards and environmental concerns drive the demand for mesh nozzle plates in the market. Regulations mandate high filtration efficiency to ensure the removal of contaminants and pollutants from industrial processes, protecting air and water quality. Additionally, there's a focus on waste reduction to minimize environmental impact, with nozzle plates playing a crucial role in optimizing material usage and reducing waste generation. Moreover, emissions control regulations require effective spraying and coating processes to minimize harmful emissions, making precision and efficiency in application crucial. Mesh nozzle plates facilitate compliance with these standards by providing precise and uniform spray patterns, ensuring efficient filtration, and minimizing material waste and emissions, thus addressing regulatory requirements while promoting environmentally sustainable practices in various industries.

Request for a sample copy of this report: https://www.imarcgroup.com/mesh-nozzle-plates-market/requestsample

What are the growth prospects and trends in the mesh nozzle plates industry?

The increasing industrialization across various sectors, such as chemicals, pharmaceuticals, automotive, and food processing represents one of the key factors influencing the growth of the market across the globe. These plates are integral components used in applications such as filtration, spraying, coating, and atomization processes, facilitating the production of a wide range of products. Technological advancements and innovations in nozzle plate designs are enhancing their performance and efficiency, leading to greater adoption across industries.

Manufacturers are developing nozzle plates with improved durability, precision, and resistance to corrosion, meeting the evolving needs of industrial applications. Additionally, stringent regulatory standards and environmental concerns are driving the demand for efficient filtration and spraying solutions.

What is included in market segmentation?

The report has segmented the market into the following categories:

Breakup by Material Type:

- Metal and Alloys

- Engineered Plastic

- Ceramic or Piezoceramics

Metal and alloys represent the largest material type segment in the market due to their durability, corrosion resistance, and suitability for various industrial applications, including filtration, chemical processing, and automotive.

Breakup by Application:

- Medical

- Electronics

- Cosmetics

- Others

Cosmetics is the largest application segment in the market because mesh nozzle plates are commonly used in cosmetic manufacturing processes, such as spraying perfumes, lotions, and other beauty products, requiring precise and uniform droplet distribution.

Market Breakup by Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe is the largest region in the market owing to its strong industrial base, particularly in sectors such as chemicals, pharmaceuticals, and cosmetics, which are major users of mesh nozzle plates, as well as stringent quality standards driving demand for high-performance filtration and spraying equipment.

Who are the key players operating in the industry?

The report covers the major market players including:

- Informatic Component Technology Limited

- MicroBase Technology Corporation

- Veco B.V. (IDEX Corporation)

Browse the full report with TOC and List of Figures: https://www.imarcgroup.com/mesh-nozzle-plates-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

USA: +1-631-791-1145 | Asia: +91-120-433-0800

Email: sales@imarcgroup.com

LinkedIn: https://www.linkedin.com/company/imarc-group/mycompany/