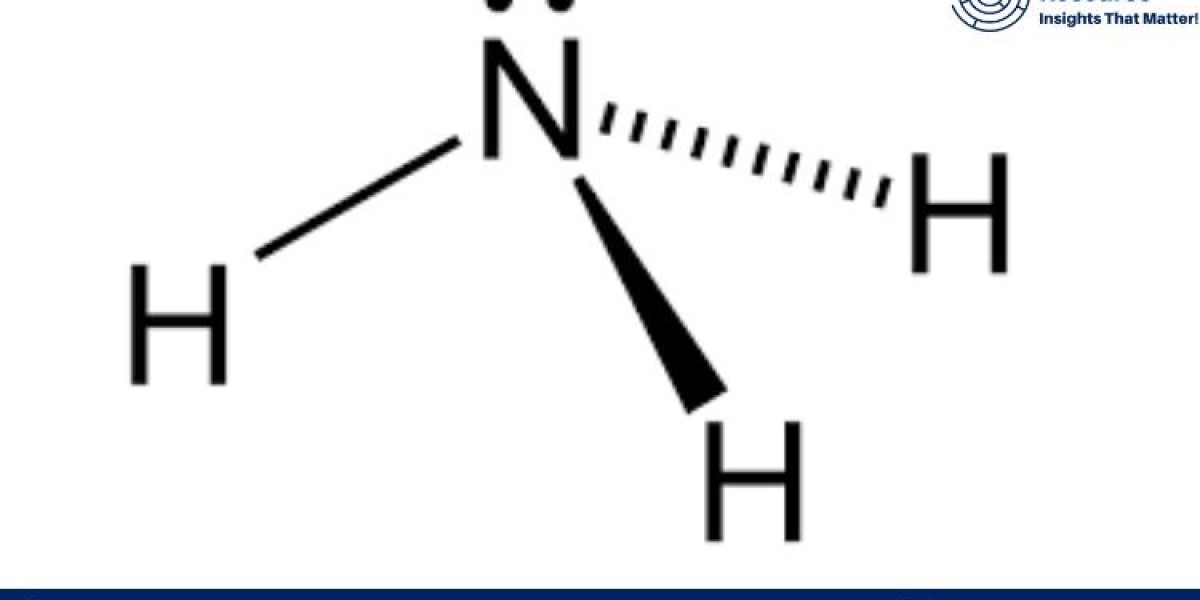

Ammonia, a compound of nitrogen and hydrogen with the chemical formula NH3, is one of the most essential chemicals in the global chemical industry. It serves as a building block for various products, including fertilizers, explosives, plastics, and pharmaceuticals. Understanding the Production Cost of Ammoniais crucial for producers, investors, and policymakers to make informed decisions and navigate the complexities of the chemical market.

Introduction to Ammonia Production

Ammonia is primarily produced through the Haber-Bosch process, a catalytic reaction between nitrogen and hydrogen under high temperature and pressure. The raw materials for ammonia production are nitrogen, typically sourced from the air through nitrogen fixation, and hydrogen, which is often derived from natural gas or steam reforming of hydrocarbons.

Ammonia Market Overview

The global demand for ammonia is driven by its extensive use in agriculture as a key component of nitrogen-based fertilizers. Additionally, ammonia is used in the production of various chemicals, including ammonium nitrate for explosives, urea for fertilizers and plastics, and hydrazine for rocket fuel and pharmaceuticals. The demand for ammonia is closely tied to agricultural activities, industrial production, and infrastructure development.

Factors Affecting Ammonia Production Cost

Several factors influence the production cost of ammonia:

Feedstock Prices: The prices of nitrogen and hydrogen, the primary feedstocks for ammonia production, directly impact production costs. Fluctuations in natural gas prices, which is a common source of hydrogen, can significantly affect the cost of ammonia production.

Energy Costs: Ammonia production is energy-intensive, requiring large amounts of heat and electricity to drive the Haber-Bosch reaction and subsequent separation and purification processes. Energy costs, including electricity, natural gas, and other fuel sources, contribute significantly to the overall production cost.

Capital Investment: The capital investment required to build and operate an ammonia production plant, including infrastructure, equipment, and facilities, influences production costs. Factors such as plant size, technology, and location play a role in determining the capital expenditure and, consequently, the cost of production.

Technology and Process Efficiency: Advances in technology and process efficiency can optimize ammonia production processes, reduce energy consumption, and improve yields, thereby lowering production costs. Innovation in catalyst development, reactor design, and process optimization contributes to cost competitiveness in the ammonia industry.

Operating and Maintenance Costs: Operating and maintenance costs, including labor, maintenance, repairs, and overhead expenses, impact the overall cost structure of ammonia production. Efficient management practices and preventive maintenance strategies can help minimize these costs and improve profitability.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/ammonia/request-sample

Global Ammonia Production Cost Analysis

The production cost of ammonia varies across regions and depends on factors such as feedstock availability, energy prices, labor costs, and regulatory requirements. For example, regions with abundant natural gas reserves, such as the Middle East and North America, may have lower production costs due to access to low-cost feedstocks. Conversely, regions with higher energy costs or stringent environmental regulations may incur higher production costs.

Future Outlook and Opportunities

The ammonia industry is facing several challenges and opportunities in the coming years:

Sustainability and Environmental Concerns: Increasing focus on sustainability and environmental regulations is driving the adoption of cleaner and more energy-efficient ammonia production technologies. Green ammonia production methods, such as electrolysis of water using renewable energy sources, offer potential opportunities to reduce carbon emissions and enhance environmental performance.

Technological Innovation: Continued innovation in ammonia production technologies, including advanced catalysis, process intensification, and carbon capture and utilization (CCU) technologies, can improve efficiency, reduce costs, and mitigate environmental impacts.

Market Dynamics: Shifts in global demand patterns, emerging markets, and geopolitical developments can impact ammonia prices and market dynamics. Producers and stakeholders need to monitor market trends, anticipate changes, and adapt their strategies accordingly to remain competitive.

Value-Added Products: Exploring value-added products and downstream applications of ammonia, such as hydrogen fuel cells, green fertilizers, and ammonia-based chemicals, presents opportunities for market expansion and diversification.

Conclusion

In conclusion, understanding the production cost of ammonia is essential for stakeholders in the chemical industry to assess profitability, competitiveness, and sustainability. By analyzing key cost drivers, technological advancements, and market trends, producers, investors, and policymakers can navigate the complexities of the ammonia market and capitalize on emerging opportunities for growth and innovation.