Coding and marking equipment form a critical component of modern manufacturing and packaging processes, facilitating the identification, tracking, and traceability of products throughout their lifecycle. These technologies encompass a range of solutions, from inkjet and laser printing to thermal transfer overprinting (TTO), each tailored to meet specific industry needs for clarity, durability, and regulatory compliance. As industries worldwide continue to prioritize efficiency, safety, and sustainability, the coding and marking equipment market is poised for significant growth and evolution.

Importance in Modern Manufacturing

In today's interconnected global marketplace, accurate and reliable product identification is essential for regulatory compliance, supply chain management, and consumer safety. Coding and marking equipment ensures that vital information such as batch numbers, expiry dates, barcodes, and regulatory symbols are clearly and permanently applied to products and packaging materials. This capability not only facilitates seamless inventory management but also enhances brand protection and consumer trust by preventing counterfeiting and ensuring product authenticity.

Market Dynamics and Growth Drivers

The coding and marking equipment market is driven by several key factors that contribute to its current size and future growth prospects:

- Regulatory Compliance: Stringent regulations across industries such as pharmaceuticals, food and beverage, and electronics mandate the accurate labeling and traceability of products. This regulatory landscape continues to fuel demand for advanced coding solutions capable of meeting evolving compliance requirements.

- Technological Advancements: Ongoing innovations in printing technologies, including advancements in ink formulations, print heads, and software integration, are enhancing the capabilities and performance of coding and marking equipment. Manufacturers are increasingly adopting automated and digital solutions that offer improved efficiency, flexibility, and print quality.

- Industry 4.0 Integration: The convergence of coding and marking equipment with Industry 4.0 technologies, such as Internet of Things (IoT) connectivity and data analytics, is transforming manufacturing operations. Real-time monitoring, predictive maintenance, and seamless integration with production lines are becoming standard features, driving operational efficiencies and reducing downtime.

Market Size and Current Landscape

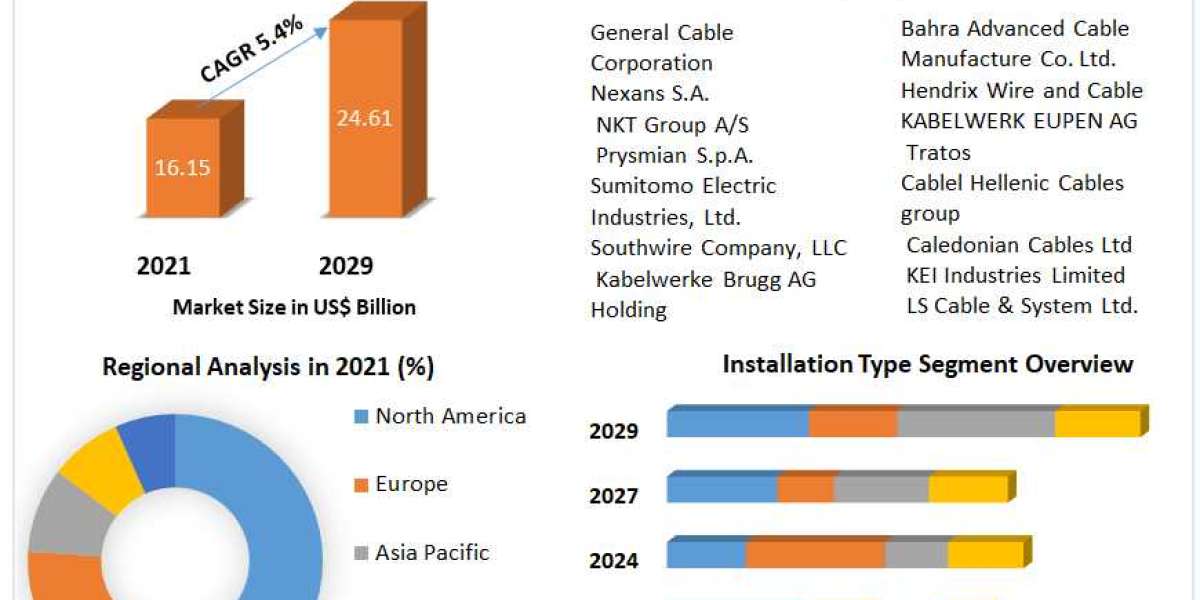

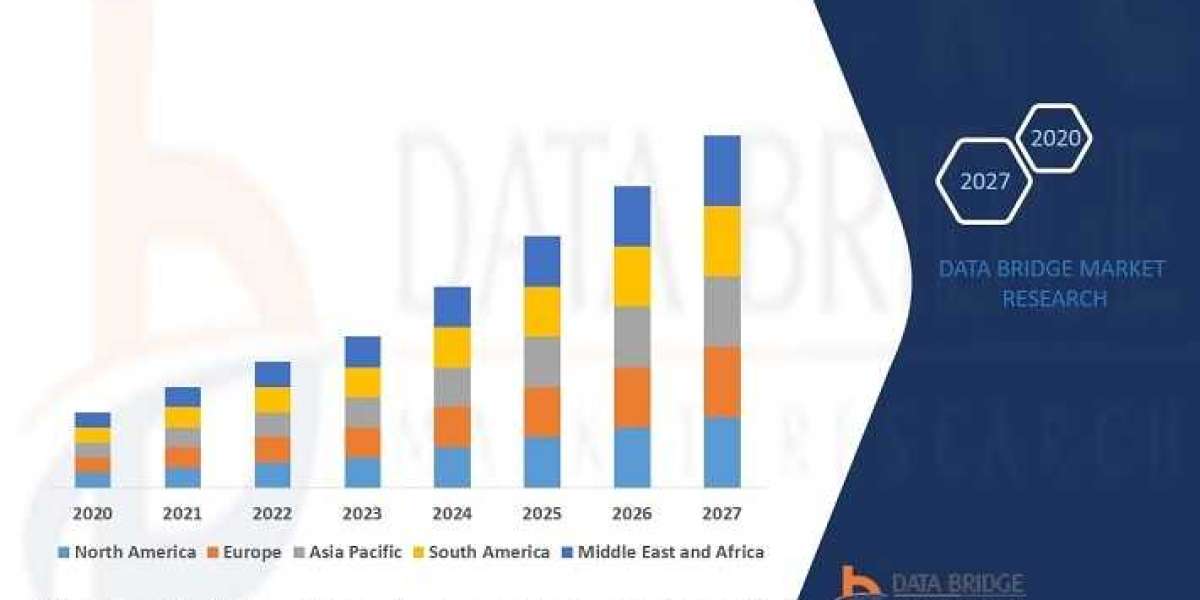

According to Stratview Research, the global Coding and marking equipment market size was valued at USD 15.96 billion in 2022 and it is projected to reach USD 22.07 billion by 2028, growing at a CAGR of 5.50% during forecast period of 2023-2028. This growth trajectory underscores the increasing adoption of automated coding solutions across diverse end-user industries:

- Food and Beverage: The largest consumer of coding and marking equipment, driven by stringent regulations governing product labeling, traceability, and food safety standards. Advanced inkjet and laser printing technologies are preferred for their ability to print on various substrates while maintaining compliance with food-grade requirements.

- Pharmaceuticals: Critical for ensuring product authenticity, serialization, and anti-counterfeiting measures. High-resolution printing technologies capable of encoding detailed information on small packaging surfaces are in high demand to meet regulatory mandates and enhance patient safety.

- Automotive and Electronics: Demand for durable marking solutions that withstand harsh environmental conditions and ensure part traceability throughout the supply chain. Laser marking and thermal transfer overprinting technologies are commonly used for marking components, electronic devices, and automotive parts.

Future Predictions and Emerging Trends

Looking ahead, several trends are expected to shape the future of the coding and marking equipment market:

- Sustainability Initiatives: Increasing emphasis on sustainable packaging solutions is driving innovations in eco-friendly ink formulations and recyclable packaging materials. Manufacturers are exploring greener alternatives to traditional printing methods to reduce environmental impact.

- Enhanced Connectivity: Continued integration of coding and marking equipment with digital platforms and cloud-based systems for centralized control, remote monitoring, and data analytics. This connectivity enables real-time insights into production metrics, quality assurance, and supply chain visibility.

- Rise of Smart Packaging: Growing interest in smart packaging technologies incorporating RFID tags, QR codes, and NFC (Near Field Communication) for enhanced product information, consumer engagement, and supply chain optimization.

- Global Expansion: Expansion into emerging markets in Asia-Pacific, Latin America, and Africa, driven by industrialization, urbanization, and increasing consumer demand for packaged goods. Market players are leveraging these opportunities to expand their footprint and cater to diverse regional requirements.

Conclusion

In conclusion, the coding and marking equipment market continues to evolve rapidly, driven by technological advancements, regulatory mandates, and the growing demand for operational efficiency and product safety. As manufacturers across industries embrace automation and digitalization, the role of coding and marking equipment in ensuring product integrity and supply chain transparency will remain pivotal. With ongoing innovation and strategic investments in sustainable practices and connectivity, the future promises robust growth and transformative opportunities for stakeholders in the global coding and marking equipment market.