Digital twins are transforming manufacturing processes by providing a virtual replica of physical assets, processes, or systems. This technology enables real-time monitoring, simulation, and optimization, leading to significant improvements in efficiency, productivity, and innovation. In this article, we will explore how digital twins are revolutionizing the manufacturing sector.

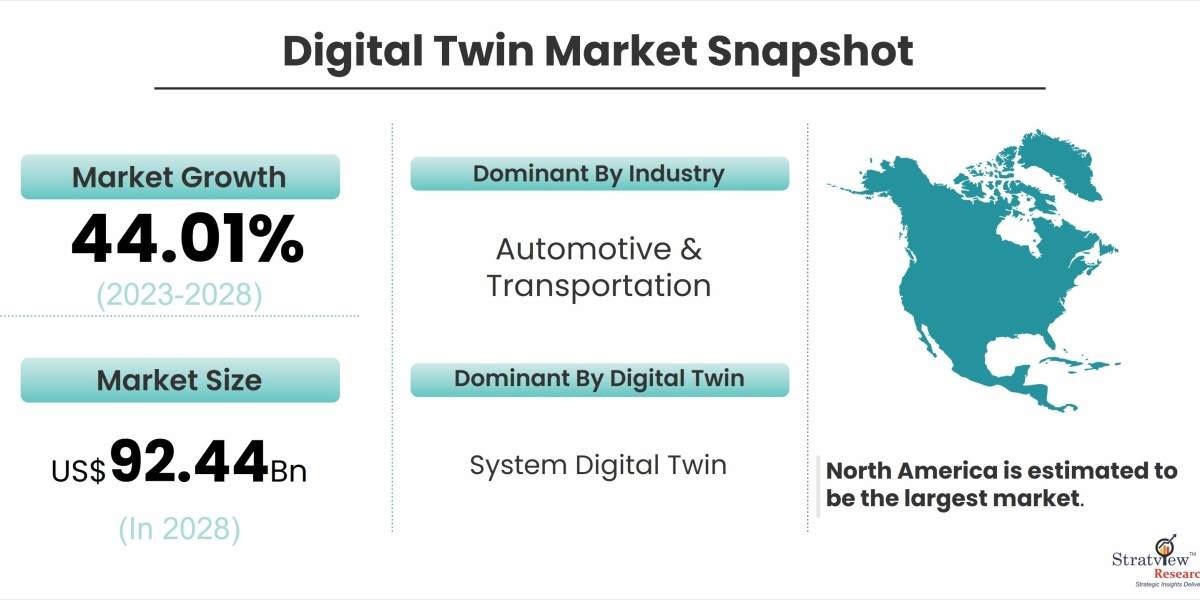

According to Stratview Research, the digital twin market was estimated at USD 10.36 billion in 2022 and is likely to grow at a CAGR of 44.01% during 2023-2028 to reach USD 92.44 billion in 2028.

Real-Time Monitoring and Predictive Maintenance

Digital twins allow manufacturers to monitor their equipment and production lines in real time. By integrating sensors and IoT devices with digital twin models, manufacturers can collect and analyze data on the performance, condition, and usage of their machinery. This real-time insight helps identify potential issues before they become critical, enabling predictive maintenance. Predictive maintenance reduces unplanned downtime, extends the life of equipment, and minimizes maintenance costs.

Enhanced Product Design and Development

The use of digital twins in product design and development is a game-changer. Engineers can create virtual prototypes and simulate various scenarios to test the performance, durability, and functionality of new products. This virtual testing accelerates the design cycle, reduces the need for physical prototypes, and helps identify design flaws early in the process. As a result, manufacturers can bring high-quality products to market faster and at a lower cost.

Process Optimization and Efficiency

Digital twins enable manufacturers to optimize their production processes by providing a comprehensive view of the entire manufacturing system. By simulating different production scenarios, manufacturers can identify bottlenecks, inefficiencies, and areas for improvement. This optimization leads to streamlined operations, reduced waste, and increased productivity. For example, companies like Siemens use digital twins to optimize their production lines, resulting in significant cost savings and enhanced efficiency.

Quality Control and Assurance

Maintaining high-quality standards is crucial in manufacturing. Digital twins help achieve this by providing detailed insights into the production process and enabling real-time quality monitoring. Manufacturers can use digital twins to detect deviations from quality standards, analyze root causes, and implement corrective actions. This proactive approach ensures consistent product quality, reduces defects, and enhances customer satisfaction.

Supply Chain Management

Digital twins extend their benefits beyond the factory floor to the entire supply chain. By creating digital replicas of supply chain processes, manufacturers can gain visibility into inventory levels, logistics, and supplier performance. This visibility enables better demand forecasting, inventory management, and coordination with suppliers. Digital twins also help identify risks and disruptions in the supply chain, allowing manufacturers to take proactive measures to mitigate them.

Sustainability and Environmental Impact

Sustainability is a growing concern in the manufacturing industry. Digital twins contribute to sustainability efforts by optimizing resource usage, reducing waste, and minimizing energy consumption. By simulating different production scenarios, manufacturers can identify the most sustainable and efficient processes. Additionally, digital twins enable the monitoring of environmental parameters, such as emissions and energy usage, helping manufacturers comply with regulations and reduce their environmental footprint.

Conclusion

Digital twins are revolutionizing manufacturing processes by providing real-time insights, enabling predictive maintenance, enhancing product design, optimizing production, ensuring quality control, improving supply chain management, and promoting sustainability. As this technology continues to advance, its impact on the manufacturing sector will only grow, driving further innovation and efficiency. Embracing digital twin technology is essential for manufacturers looking to stay competitive and thrive in the digital age.