There are many other types of portable air compressors, but they are all covered by 12-volt, household or small air compressors. The portable compressor is driven by a large diesel engine. The size of the engine and compressor depends on the required air flow and air pressure. Portable air compressors can usually provide a pressure of 7 to 12 bar. The amount of air (air flow) they can produce per minute varies by type.

What size compressor you need depends on the pneumatic tool you use.

Do they need a lot of air? Do you need high pressure?

In construction and general use, most pneumatic tools require a pressure of about 7 bar, but the air flow rate varies greatly.

Who uses portable compressors?

Portable air compressors are used to provide compressed air on construction sites, on road projects, or wherever people who are not suitable for stationary compressors need compressed air.

They are also used as (emergency) backup compressors in factories, for example when their stationary compressors need maintenance or stop working. They are powered by diesel engines and therefore do not require electricity.

Portable air compressors need to be robust and reliable. They are usually used in dusty environments, so high-quality air filters are necessary.

They need to work under various conditions, such as very cold weather or high altitude (for example, compressed air is used to make snow for skiing), but they must also work in dusty, hot or humid environments.

The above requirements apply to compressor components and diesel engines. The diesel engine must be robust and reliable.

The worst case that can happen is that your compressor does not work properly anywhere and gets stuck without compressed air.

compressor

In almost all cases, the compressor is of the rotary screw type. It can be oil-filled or oil-free, although oil-free compressors are very expensive and are only used for special applications (for example, large Atlas Copco oil-free portable compressors can only be rented, not purchased (in Europe) Minimum).

Therefore, 99% of portable compressors are oil-injected single-stage rotary screw compressors. They work in almost the same way as stationary electric screw compressors. Although there are some subtle differences, especially in the control system.

diesel engine

Diesel engines are used to drive portable air compressors. They are robust, reliable, and can run for hours or weeks at a time.

The engine is either directly coupled to the compressor element or connected to pulleys and belts. Just like your car, the engine uses a starter motor to start, so the portable compressor also has a battery.

Operation and control system

The engine has (minimum requirements) safety measures for low oil pressure and/or oil level and excessive temperature. The speed of the engine is controlled by the compressor control system.

In most cases, this is a fairly simple control system (full pneumatic, minimal electronic equipment). Especially compared to stationary compressors, today stationary compressors have control panels with sophisticated microcontrollers and many settings and options.

Not a portable compressor... It basically has a start/stop button, sometimes a load/unload button, no indicator light and an hour counter.

Option

Portable air compressors have many different options and additional functions. The basic options of portable air compressors include:

-After cooling

-Moisture collector, filter for dust, oil, water or smoke (depending on the required compressed air quality)

-Reheat (heat the cooled air to prevent moisture problems)

-Different towbar designs (depending on your car/truck)

-Heavy-duty compressor air intake filter (for dusty environments).

-Cold start (for operation in cold areas)

–Spark arrester

–Inlet stop valve

If a portable air compressor is used in an explosive or flammable environment, install a spark plug on the exhaust pipe to prevent any sparks from flying out and catching fire. The law may require them to be used in certain places on the planet (for example, especially in forests or in chemical/refineries).

When portable air compressors are used in environments where chemicals or combustible gases may be present in the air (such as in oil refineries or chemical plants), the air intake shutoff valve is required.

Diesel engines may inhale flammable gases. The gas will ignite in the diesel engine and cannot be stopped. Otherwise it may "go crazy" and start running faster and faster. Therefore, a shut-off valve is installed in the air supply (behind the air filter). In this case, it will shut off the air supply.

Portable air compressor parts and maintenance

Since you are using portable compressors in remote areas, you first need to rely on portable compressors.

Good maintenance is very important to keep the compressor running smoothly.

It may be a good idea to keep some necessary spare parts so that if the compressor crashes unexpectedly, you can start and run immediately.

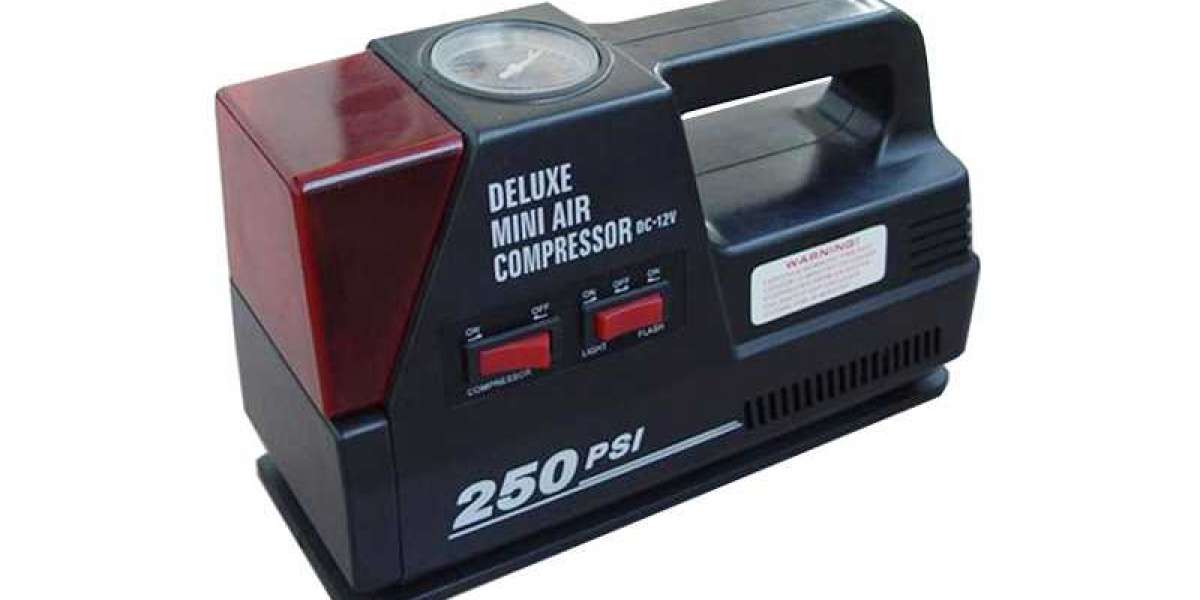

Linsheng Electrical Company mainly produces air compressors for automobiles. Is a professional of Air compressor Suppliers . Our air compressor has a built-in pressure gauge, which is compact and low power consumption. It can quickly inflate ordinary tires, such as car tires, bicycle tires and sports balls, in 5 to 6 minutes. Our products are exported to customers in the United States, Europe, Africa and Asia and other countries and regions. We also welcome OEM and ODM orders. https://www.linsheng.com/product/air-compressor-product/