Polyester geogrid is a crucial component in modern civil engineering and construction projects, particularly in areas that require ground reinforcement. It is a high-strength, geosynthetic material used to improve the mechanical properties of soil and enhance the structural integrity of infrastructures such as roads, embankments, retaining walls, and more. Made from polyester fibers, this geogrid provides high tensile strength, excellent creep resistance, and superior durability, making it ideal for long-term reinforcement applications.

This article will delve into the characteristics, benefits, applications, and environmental considerations of Polyester Geogrid for Road Construction. Additionally, we will answer frequently asked questions (FAQs) to provide a comprehensive understanding of this essential material.

What is a Polyester Geogrid?

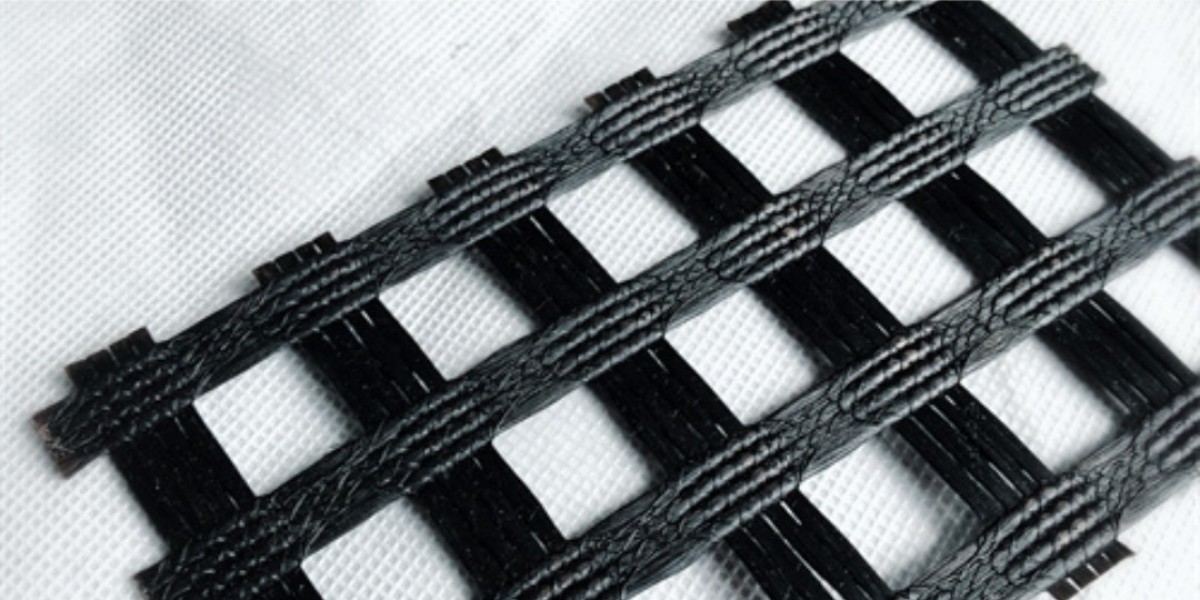

A polyester geogrid is a type of geosynthetic material made from polyester fibers that are woven into a grid-like structure. The primary function of the geogrid is to reinforce weak soils by providing additional tensile strength, preventing deformation, and enhancing load distribution. The grid structure allows soil particles to interlock with the geogrid, increasing the stability of the soil mass and reducing the risk of shifting, erosion, or settlement.

Polyester geogrids are known for their high tensile strength and resistance to stretching (low elongation). The polyester fibers provide excellent resistance to creep (permanent deformation under constant load), ensuring that the geogrid maintains its performance over time, even under heavy loads.

Manufacturing Process of Polyester Geogrid

The manufacturing process of polyester geogrid involves the following steps:

Extrusion: Polyester fibers are extruded from a polymer melt and then drawn to enhance their tensile strength. These fibers form the base material for the geogrid.

Knitting or Weaving: The polyester fibers are knitted or woven into a grid pattern. The grid structure creates openings that allow soil particles to interlock with the geogrid, improving the load-bearing capacity of the soil.

Coating: The woven or knitted polyester grid is coated with a protective polymer (typically PVC or another plastic material) to enhance its durability, resistance to chemicals, and UV protection. The coating also helps bind the fibers together, creating a stable and uniform structure.

Quality Control: The finished polyester geogrid undergoes rigorous quality control tests to ensure it meets the required standards for tensile strength, elongation, and resistance to environmental factors such as UV exposure and chemicals.

Key Features of Polyester Geogrid

Polyester geogrid has a range of features that make it suitable for reinforcement in various civil engineering and construction projects:

High Tensile Strength: One of the primary benefits of polyester geogrid is its high tensile strength. This characteristic allows it to reinforce weak soils, preventing deformation and enhancing the overall stability of the structure.

Low Creep: Polyester geogrid exhibits excellent resistance to creep, ensuring that it maintains its strength and performance even under constant loading over long periods. This makes it particularly suitable for long-term reinforcement applications.

Chemical Resistance: Polyester geogrid is resistant to most chemicals, including alkalis, acids, and organic compounds. This makes it a suitable material for use in environments where exposure to aggressive chemicals is a concern.

UV Resistance: The protective coating applied to the polyester geogrid helps it resist degradation from UV radiation, ensuring that it can withstand prolonged exposure to sunlight without losing its structural integrity.

Durability: Polyester geogrid is designed to withstand harsh environmental conditions, including temperature fluctuations, moisture, and mechanical stress. Its durability makes it suitable for both temporary and permanent reinforcement applications.

Flexibility: Polyester geogrid is flexible enough to conform to the contours of the terrain, making it easier to install in challenging environments such as steep slopes or uneven ground.

Lightweight and Easy to Handle: Despite its strength, polyester geogrid is lightweight and easy to transport and handle during installation. This reduces labor costs and speeds up construction projects.

Cost-Effective: Polyester geogrid is a cost-effective solution for ground reinforcement, as it reduces the need for expensive soil replacement or additional foundation work. It provides long-term performance while minimizing maintenance and repair costs.

Applications of Polyester Geogrid

Polyester geogrid is used in a wide range of civil engineering and construction projects. Some of the most common applications include:

Road Construction: Polyester Geogrid Reinforcement is commonly used to reinforce the base and subgrade layers of roads. It helps distribute the load from traffic more evenly across the soil, reducing the risk of deformation, rutting, and cracking. This leads to longer-lasting road surfaces and reduced maintenance costs.

Embankment Reinforcement: Polyester geogrid is used to reinforce embankments and slopes, preventing soil erosion and providing additional stability. It helps reduce the risk of landslides and ensures the long-term integrity of the embankment.

Retaining Walls: Polyester geogrid is used to reinforce retaining walls by providing additional tensile strength to the soil behind the wall. This prevents soil movement and helps the wall withstand the pressure exerted by the retained soil.

Railway Construction: In railway construction, polyester geogrid is used to reinforce the ballast and subgrade layers. It helps distribute the load from passing trains more effectively, reducing the risk of track deformation and improving overall safety.

Landfill and Waste Containment: Polyester geogrid is used in the construction of landfills and waste containment facilities to reinforce the underlying soil and prevent settlement. It also helps stabilize the sides of the landfill, reducing the risk of slope failure.

Slope Stabilization: Polyester geogrid is used to stabilize steep slopes by reinforcing the soil and preventing erosion. It is often used in combination with vegetation to create green slopes that are both stable and environmentally friendly.

Pavement Rehabilitation: Polyester geogrid is used in pavement rehabilitation projects to reinforce the existing pavement layers and reduce the risk of cracking and rutting. This helps extend the lifespan of the pavement and reduces the need for frequent repairs.

Bridge Abutment Reinforcement: Polyester geogrid is used to reinforce the soil behind bridge abutments, preventing settlement and ensuring the long-term stability of the bridge.

Environmental Considerations

The use of polyester geogrid in construction projects offers several environmental benefits. By reinforcing the soil and improving load distribution, geogrids reduce the need for extensive earthworks and soil replacement, which minimizes the environmental impact of construction projects. Additionally, polyester geogrid can be manufactured from recycled materials, further reducing its environmental footprint.

Moreover, the long lifespan of polyester geogrid means that structures reinforced with this material require less maintenance and fewer repairs, reducing the consumption of resources and energy over time. As construction industries continue to prioritize sustainability, Polyester Geogrid Installation is expected to play an increasingly important role in eco-friendly building practices.

Frequently Asked Questions (FAQs) About Polyester Geogrid

Q1: What is polyester geogrid used for?

A1: Polyester geogrid is used for ground reinforcement in various civil engineering and construction projects. Common applications include road construction, embankment reinforcement, retaining walls, railway construction, landfill stabilization, and slope stabilization.

Q2: What are the benefits of using polyester geogrid?

A2: Polyester geogrid provides high tensile strength, low creep, chemical and UV resistance, durability, flexibility, and cost-effectiveness. It reinforces weak soils, improves load distribution, and enhances the stability and longevity of structures.

Q3: How is polyester geogrid installed?

A3: Polyester geogrid is typically installed by laying it over the soil surface or embedding it within soil layers during construction. The geogrid must be properly tensioned and anchored to ensure effective reinforcement.

Q4: Can polyester geogrid be used in environmental projects?

A4: Yes, polyester geogrid is commonly used in environmental projects such as landfill containment and slope stabilization. It helps prevent soil erosion and reduces the environmental impact of construction activities by minimizing the need for extensive earthworks.