Introduction

The Sophorolipids Production Process with Cost Analysis provides a comprehensive overview of the sophisticated methods used to produce sophorolipids, including a detailed examination of associated costs. Sophorolipids are a type of biosurfactant produced by yeast fermentation, and they have applications in various industries due to their environmentally friendly properties. Understanding the production process and cost implications is vital for businesses and stakeholders looking to optimize operations and make informed investment decisions.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/sophorolipids/request-sample

Procurement Resource Assessment: Sophorolipids Production Process

Effective procurement is crucial for the Sophorolipids Production Process to ensure a consistent and cost-effective supply of raw materials. Key aspects of procurement resource assessment include:

Supplier Selection: Identifying and evaluating suppliers of key ingredients and equipment used in sophorolipids production. This involves assessing suppliers based on factors such as reliability, cost, quality, and compliance with sustainability and safety standards.

Quality Control: Ensuring that raw materials and intermediates meet the required specifications for effective sophorolipid production. Quality control is essential for maintaining consistency and effectiveness in the final product.

Supply Chain Management: Managing the logistics of sourcing and transporting raw materials to production facilities. This includes optimizing transportation routes, coordinating deliveries, and managing inventory levels to ensure smooth operations.

Cost Efficiency: Analyzing procurement costs, including the price of raw materials, transportation, and handling. Efficient procurement practices help in minimizing overall production costs and enhancing profitability.

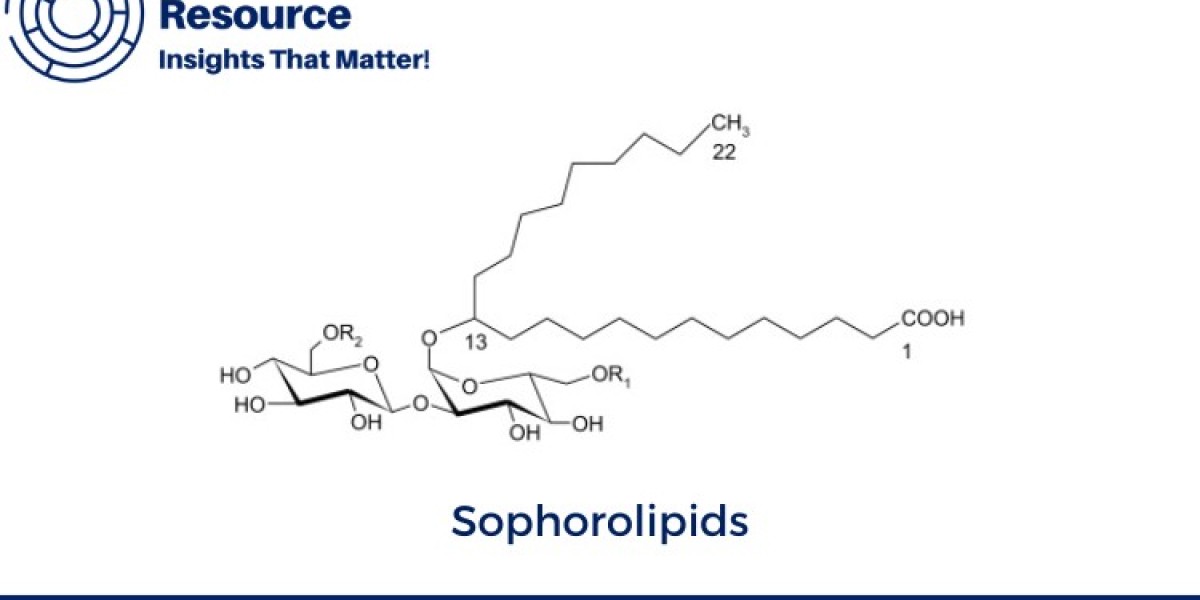

Sophorolipids: An Overview

Sophorolipids are glycolipid surfactants produced by the fermentation of sugars with yeast, typically from the genus Starmerella. They are known for their excellent surface-active properties and biodegradability. Sophorolipids have applications in various industries, including:

Cosmetics and Personal Care: Used in skincare and haircare products for their gentle cleansing and emulsifying properties.

Pharmaceuticals: Employed in drug delivery systems and as potential therapeutic agents due to their biocompatibility.

Agriculture: Used as eco-friendly soil wetting agents and in biopesticides.

Cleaning Products: Applied in eco-friendly detergents and cleaners due to their biodegradability and low toxicity.

The production of sophorolipids involves fermentation, extraction, and purification processes, each contributing to the overall cost and quality of the final product.

Market Drivers

Several factors drive the Sophorolipids Market, influencing production and pricing. Key market drivers include:

Increasing Demand for Biodegradable Products: Growing awareness of environmental issues and sustainability drives demand for biodegradable surfactants like sophorolipids. Consumers and businesses are increasingly seeking eco-friendly alternatives to conventional surfactants.

Advancements in Biotechnology: Innovations in fermentation and production technologies enhance the efficiency and scalability of sophorolipid production. Technological advancements contribute to lower production costs and improved product quality.

Regulatory Support: Government regulations and policies promoting the use of sustainable and environmentally friendly products support the growth of the sophorolipids market. Incentives and subsidies for green technologies further drive market demand.

Growth in End-Use Industries: Expansion in industries such as cosmetics, pharmaceuticals, and cleaning products fuels the demand for sophorolipids. The increasing application of sophorolipids in various sectors contributes to market growth.

Consumer Preference for Natural Products: The trend towards natural and organic products boosts the demand for sophorolipids, which are derived from natural sources and offer favorable safety profiles compared to synthetic alternatives.

Raw Materials Requirements

The Raw Materials Requirements for sophorolipids production include:

Sugars and Carbohydrates: The primary raw materials for sophorolipid production are sugars or carbohydrates, which serve as the carbon source for yeast fermentation. Commonly used substrates include glucose, fructose, and sucrose.

Yeast Cultures: Specific strains of yeast, such as Starmerella bombicola, are used for fermentation. The selection of yeast strains and their maintenance are critical for optimizing sophorolipid production.

Nutrient Additives: Additional nutrients, including nitrogen sources, vitamins, and minerals, are required to support yeast growth and fermentation efficiency.

Water: High-quality water is essential for fermentation, extraction, and purification processes. Ensuring a clean and sufficient water supply is crucial for maintaining product quality and process efficiency.

Chemicals and Solvents: Various chemicals and solvents are used in extraction and purification processes. These may include organic solvents, acids, and bases, which play a role in isolating and refining sophorolipids.

Costs and Key Process Information

Understanding the Costs and Key Process Information is essential for managing the financial aspects of sophorolipid production. Key cost factors include:

Raw Material Costs: The cost of acquiring and processing sugars, yeast cultures, and other raw materials. Fluctuations in raw material prices can significantly impact overall production costs.

Energy Costs: The cost of energy required for fermentation, extraction, and purification processes. Efficient energy management and cost control are critical for maintaining profitability.

Labor Costs: Labor costs associated with operating production equipment, managing processes, and ensuring quality control. Skilled labor and effective workforce management contribute to overall operational efficiency.

Equipment and Maintenance: Costs related to purchasing, maintaining, and upgrading production equipment, including fermenters, separators, and purification systems. Regular maintenance and timely upgrades are essential for minimizing downtime and optimizing production efficiency.

Regulatory Compliance Costs: Costs associated with meeting regulatory requirements, including safety, environmental, and quality standards. Investments in compliance measures ensure product quality and avoid legal issues.

Research and Development: Costs related to developing new formulations, improving production processes, and conducting quality testing. R&D investments contribute to innovation and competitive advantage.

Looking for an Exhaustive and Personalized Report

For businesses seeking a comprehensive and tailored analysis of the sophorolipids production process, an exhaustive and personalized report offers valuable insights and support. This report should include:

Detailed Cost Analysis: A thorough examination of all cost components, including raw materials, energy, labor, and equipment. This analysis helps in identifying cost-saving opportunities and optimizing production processes.

Market Trends and Forecasts: Insights into current market trends, demand forecasts, and competitive analysis. Understanding these factors aids in making informed strategic decisions and planning for future growth.

Process Optimization Recommendations: Suggestions for improving production efficiency, reducing costs, and enhancing product quality. Personalized recommendations based on specific business needs and market conditions drive better performance and profitability.

Regulatory and Compliance Information: An overview of relevant regulations and industry standards affecting sophorolipid production. Ensuring compliance with these requirements is crucial for maintaining product quality and avoiding legal issues.

Risk Management Strategies: Identifying potential risks and challenges in the production process and providing strategies to mitigate them. Effective risk management helps in maintaining production continuity and managing uncertainties.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA