Concrete is one of the most widely used construction materials in the world due to its strength, durability, and versatility. However, despite its robust nature, concrete is inherently porous, which makes it susceptible to various forms of damage over time. This is where concrete sealers come into play. They serve as a protective barrier, enhancing the longevity and aesthetic appeal of concrete surfaces.

Understanding Concrete Sealers

Concrete sealers are specialized products designed to protect concrete surfaces from moisture, stains, chemicals, and other damaging elements. By forming a protective layer on or within the concrete, sealers help maintain the integrity and appearance of the surface. There are two primary categories of concrete sealers: film-forming sealers and penetrating sealers.

- Film-Forming Sealers: These create a protective film on the surface of the Concrete Sealer. Common types include acrylics, polyurethanes, and epoxies. They are often used for decorative purposes as they can enhance the color and finish of stamped or stained concrete.

- Penetrating Sealers: Unlike film-forming sealers, penetrating sealers seep into the concrete's pores and chemically bond with it. They provide protection without altering the surface appearance and are particularly effective in repelling water and deicing salts.

Types of Concrete Sealers

1. Acrylic Sealers

Acrylic sealers are popular for their ease of application and affordability. Available in both water-based and solvent-based formulations, these sealers form a thin film over the concrete surface that protects against moisture and stains while enhancing color vibrancy. They are suitable for both interior and exterior applications but may require reapplication every few years due to wear.

2. Polyurethane Sealers

Polyurethane sealers offer a thicker protective layer compared to acrylics. They are highly durable and resistant to abrasion, making them ideal for high-traffic areas such as driveways and garages. These sealers can be either water-based or solvent-based and provide excellent UV resistance, preventing yellowing over time.

3. Epoxy Sealers

Epoxy sealers create a hard, durable finish that is resistant to chemicals and heavy wear. Typically used in industrial settings or high-traffic areas, epoxy coatings can be clear or pigmented. However, they are generally recommended for indoor applications because prolonged exposure to UV light can cause discoloration.

4. Penetrating Sealers

Penetrating sealers include silanes, siloxanes, silicates, and siliconates. These products work by filling the pores in concrete to prevent moisture intrusion while allowing vapor to escape. They do not alter the appearance of the concrete surface, making them ideal for those who prefer a natural look while still ensuring protection from water damage.

Benefits of Using Concrete Sealers

- Protection from Water Damage: One of the primary functions of concrete sealers is to prevent water from penetrating the surface. This is crucial in regions with freeze-thaw cycles where trapped water can expand and cause cracking.

- Resistance to Stains: Sealers help repel oil, grease, and other contaminants that can stain unprotected concrete surfaces. This makes cleaning easier and helps maintain a pristine appearance.

- Enhanced Durability: By protecting against environmental factors such as UV rays, deicing salts, and chemicals, sealers significantly extend the lifespan of concrete surfaces.

- Improved Aesthetics: Many sealers enhance the color and finish of decorative concrete surfaces, providing a glossy or wet look that can elevate the overall appearance.

- Cost-Effectiveness: Investing in quality concrete sealing can save money in the long run by reducing repair costs associated with damaged surfaces.

Application Best Practices

To achieve optimal results when applying concrete sealers, consider these best practices:

- Surface Preparation: Properly prepare the concrete surface before application by cleaning it thoroughly to remove dirt, grease, or previous coatings. This may involve pressure washing or using chemical cleaners.

- Choose the Right Sealer: Select a sealer that suits your specific needs based on factors such as location (interior vs exterior), traffic levels (high vs low), and desired appearance (glossy vs matte).

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s guidelines regarding application methods, drying times, and recommended number of coats.

- Apply Under Optimal Conditions: Ideal weather conditions for sealing include dry days with moderate temperatures (between 50°F to 90°F). Avoid applying sealer during rain or extreme heat to ensure proper curing.

- Regular Maintenance: Depending on the type of sealer used and environmental conditions, reapplication may be necessary every few years to maintain protection levels.

Concrete sealers play an essential role in protecting your investment in concrete surfaces by enhancing durability and aesthetics while preventing damage from moisture and stains. By understanding the different types of sealers available and their respective benefits, homeowners can make informed decisions that will prolong the life of their concrete projects.

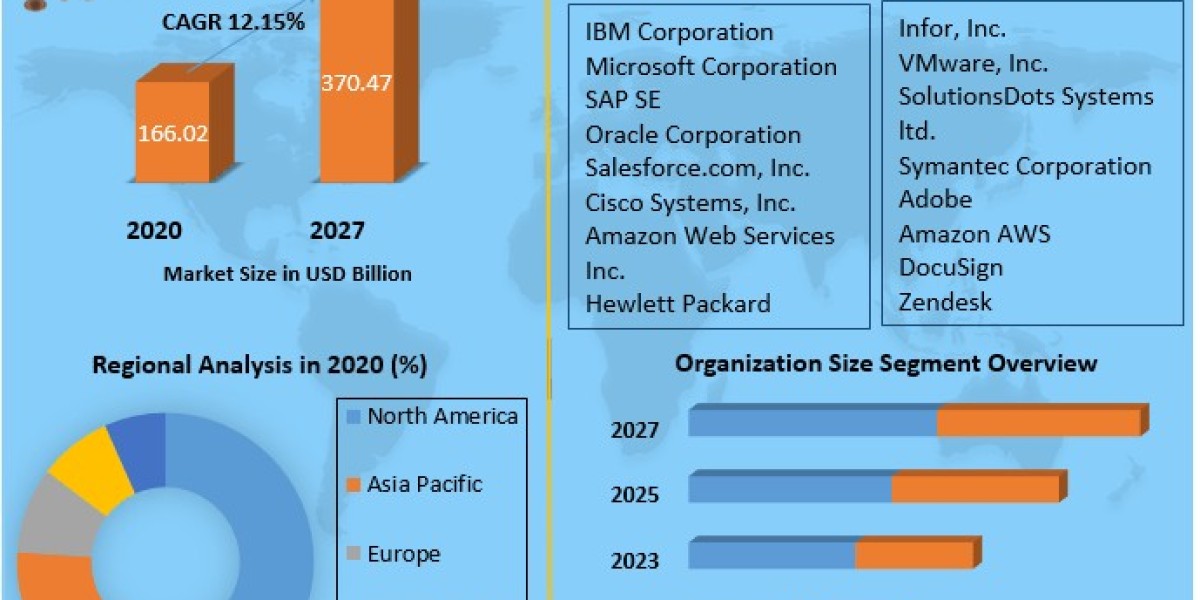

Get more insights on Concrete Sealer

Explore More Article Packaging Adhesives Market

Get More Insights—Access the Report in the Language that Resonates with You:-

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)