In today's world of construction and design, materials that offer durability, versatility, and energy efficiency are in high demand. PC hollow sheets, also known as polycarbonate hollow sheets, have emerged as one such innovative solution. These lightweight yet strong sheets are used in a variety of applications, from roofing to greenhouse panels, due to their unique properties. This article will explore the characteristics, benefits, applications, and frequently asked questions (FAQs) about Polycarbonate Hollow Sheet, providing a comprehensive understanding of this modern material.

What are PC Hollow Sheets?

PC hollow sheets are made from polycarbonate, a type of thermoplastic polymer known for its impact resistance and transparency. The "hollow" structure refers to the presence of air channels running through the sheet, which gives it a lightweight yet strong form. These air gaps also improve the sheet’s insulation properties, making it ideal for use in energy-efficient buildings and structures.

The hollow structure is typically made up of two or more layers of polycarbonate material with spaces in between, creating an internal grid of air pockets. This design enhances the thermal insulation and rigidity of the sheet without adding excessive weight.

Properties of Polycarbonate (PC)

Polycarbonate is highly valued for its unique combination of properties, such as:

- High impact resistance: Polycarbonate is nearly 200 times stronger than glass, making it highly resistant to breakage.

- Transparency: PC hollow sheets allow light transmission of up to 80-90%, which is comparable to glass, making them suitable for glazing applications.

- Lightweight: Despite its strength, polycarbonate is much lighter than glass, making it easier to handle and install.

- UV Protection: Many PC hollow sheets come with a UV coating, which protects the material from yellowing and degradation when exposed to sunlight.

- Thermal Insulation: The hollow structure provides excellent thermal insulation, reducing the need for artificial heating and cooling in buildings.

- Weather Resistance: Polycarbonate is resistant to extreme weather conditions, including rain, snow, and temperature fluctuations, making it suitable for outdoor use.

Benefits of Using PC Hollow Sheets

1. Lightweight and Easy to Install

One of the main advantages of PC hollow sheets is their lightweight nature. Unlike traditional glass, which is heavy and can be challenging to install, PC hollow sheets are easy to transport and install, reducing labor costs and time on site.

2. High Impact Resistance

PC hollow sheets are extremely durable and resistant to impact, which makes them an ideal choice for areas prone to extreme weather conditions or potential vandalism. Their strength ensures that they can withstand heavy impacts without cracking or breaking, which is especially important in safety-sensitive applications like sports facilities and public spaces.

3. Thermal Insulation

The hollow structure of these sheets provides excellent thermal insulation, helping to regulate temperatures within buildings. This property reduces the need for additional heating or cooling, contributing to energy efficiency and lower utility bills.

4. UV Protection and Weather Resistance

Most PC hollow sheets come with a UV-resistant coating, protecting them from harmful ultraviolet rays that can cause yellowing and material degradation over time. Their resistance to weather conditions makes them suitable for outdoor applications such as roofing, skylights, and greenhouses.

5. Cost-Effective

Due to their durability and long lifespan, PC hollow sheets offer a cost-effective solution compared to other materials like glass or acrylic. Their reduced need for maintenance and replacement over time adds to their overall value.

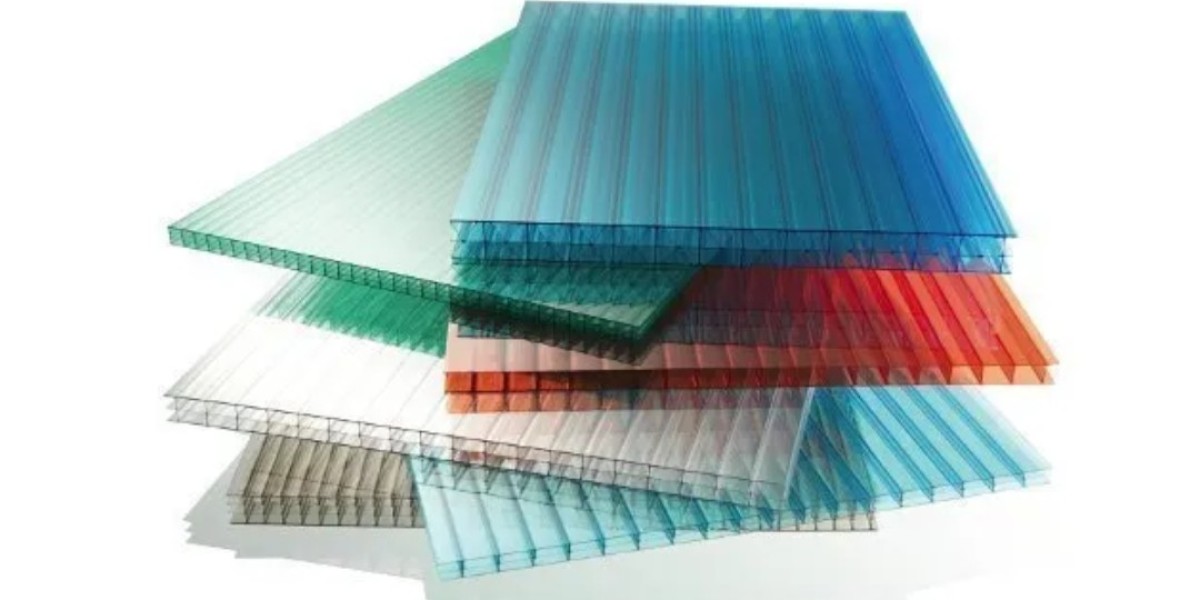

6. Versatile Design Options

PC hollow sheets are available in various thicknesses, colors, and finishes, making them a versatile option for architects and designers. Whether used for transparent roofing, decorative facades, or interior partitions, PC hollow sheets can be customized to meet specific aesthetic and functional requirements.

Common Applications of PC Hollow Sheets

1. Roofing and Skylights

PC hollow sheets are widely used in roofing applications due to their transparency, strength, and UV resistance. They allow natural light to filter through while protecting the interior from harmful UV rays and weather elements. Skylights made from polycarbonate hollow sheets are commonly installed in industrial buildings, warehouses, and homes to improve natural lighting.

2. Greenhouses

The thermal insulation and light transmission properties of PC hollow sheets make them an ideal material for greenhouses. The sheets help create a controlled environment by maintaining consistent temperatures and allowing sufficient light to penetrate for plant growth. Additionally, their lightweight design makes them easy to install in large greenhouse structures.

3. Carports and Canopies

Carports, outdoor canopies, and pergolas benefit from the use of PC hollow sheets due to their ability to provide shelter from the elements while allowing natural light to pass through. Their durability ensures that the structure remains intact even in extreme weather conditions.

4. Interior Partitions

In commercial and residential spaces, PC hollow sheets are often used as interior partitions due to their light weight, transparency, and modern appearance. They provide a stylish alternative to glass partitions while offering similar benefits in terms of light transmission and aesthetics.

5. Signage and Advertising

Polycarbonate hollow sheets are commonly used in outdoor signage and advertising boards due to their weather resistance and durability. They can withstand harsh environmental conditions without losing their clarity or structural integrity, ensuring that the signage remains visible and intact for a long time.

6. Sound Barriers

In urban areas, PC hollow sheets are sometimes used as sound barriers along highways and busy streets. Their impact resistance and sound insulation properties make them an effective solution for reducing noise pollution in densely populated areas.

How to Install PC Hollow Sheets

Proper installation of Hollow Sheet Polycarbonate is essential to ensure their performance and longevity. Here’s a step-by-step guide to installing these sheets:

1. Prepare the Frame

Ensure that the frame or structure where the PC hollow sheets will be installed is clean, level, and strong enough to support the weight of the sheets. The frame should be made from materials like aluminum, steel, or wood, depending on the application.

2. Cut the Sheets to Size

PC hollow sheets can be cut to the desired size using a fine-toothed saw or circular saw. It’s important to cut the sheets carefully to avoid chipping or cracking along the edges. Always wear safety gear while cutting the sheets.

3. Install the Sheets

Place the cut sheets onto the frame, ensuring they are positioned with the UV-protected side facing outward. If the sheets are designed with a directional feature, follow the manufacturer's instructions regarding the correct orientation.

4. Secure the Sheets

Use screws, bolts, or clamps to secure the sheets to the frame. Ensure that the fasteners are spaced evenly to avoid stress on any part of the sheet. If the sheets will expand and contract due to temperature changes, leave enough room between fasteners to accommodate this movement.

5. Seal the Edges

To prevent water, dust, or insects from entering the hollow channels, seal the edges of the sheets with appropriate tape or sealant. This step is particularly important in roofing or outdoor applications.

6. Maintain the Sheets

While PC hollow sheets are highly durable, they require occasional cleaning to remove dust, dirt, and other debris. Clean the sheets using a mild detergent and soft cloth to avoid scratching the surface.

Conclusion

PC hollow sheets offer a unique combination of durability, versatility, and energy efficiency, making them an excellent choice for a wide range of construction and design applications. Whether you’re looking for roofing, greenhouse panels, or sound barriers, Hollow Polycarbonate Sheet provide a cost-effective and long-lasting solution. By understanding their properties and installation process, you can make the most of this innovative material in your next project.

Frequently Asked Questions (FAQs)

1. What is the difference between solid and hollow polycarbonate sheets?

Solid polycarbonate sheets are made from a single layer of material, while hollow sheets feature multiple layers with air gaps in between. Hollow sheets offer better insulation, are lighter in weight, and are more affordable compared to solid sheets.

2. Can PC hollow sheets be used in hot climates?

Yes, PC hollow sheets are suitable for use in hot climates. Many sheets come with UV protection, which prevents them from degrading or yellowing due to prolonged sun exposure. They also provide excellent thermal insulation, making them ideal for energy-efficient buildings.

3. Are PC hollow sheets fire-resistant?

Polycarbonate sheets, including hollow sheets, have a high fire resistance rating. They are classified as self-extinguishing materials, meaning they won’t contribute to the spread of fire. However, they may deform when exposed to extreme heat.