In industries where machinery operates under extreme conditions, durability is non-negotiable. One key component that often faces these challenges head-on is the gearbox. Gearboxes are the backbone of many mechanical systems, translating energy into motion. But when the environment pushes them to their limits, only a premium gearbox can stand the test of time. Gearbox manufacturers have responded by crafting solutions that prioritise durability without compromising efficiency. For businesses relying on gearboxes, understanding why durability matters is crucial.

The Role of Gearboxes in Extreme Environments

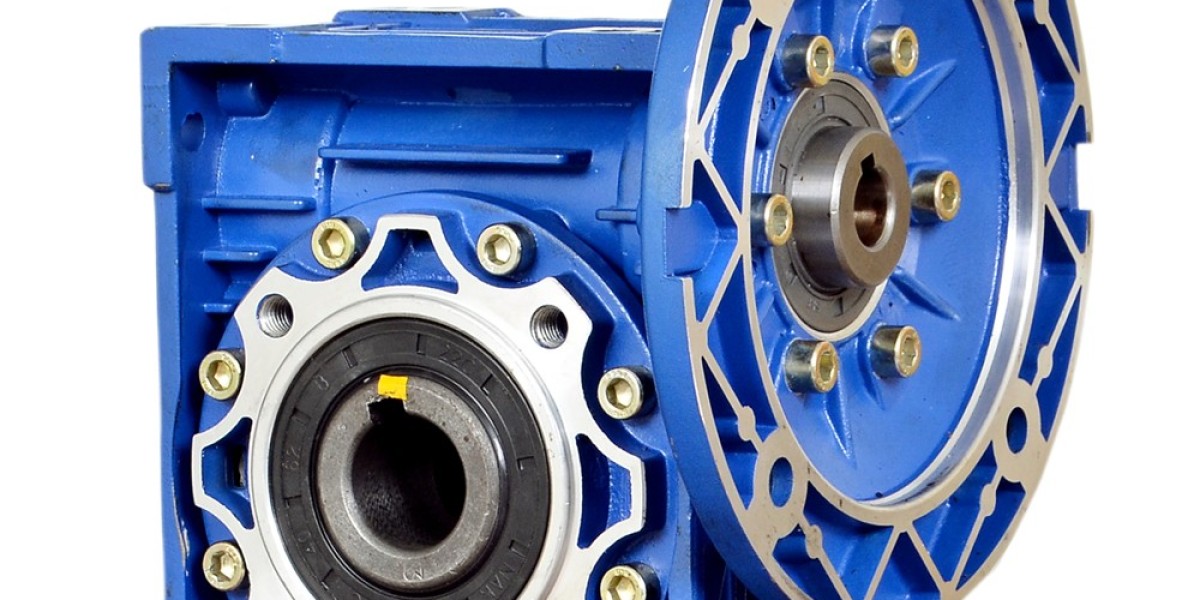

Gearboxes serve as an essential link in the mechanical chain. They convert energy from engines into usable power, adjusting torque and speed to meet specific operational requirements. In extreme environments—such as offshore drilling platforms, mining operations, or high-temperature manufacturing plants—gearboxes are exposed to various stressors. These include intense heat, heavy loads, fluctuating pressures, and abrasive materials.

A premium gearbox must function seamlessly under such conditions. Durability ensures gearboxes maintain their operational integrity despite wear, corrosion, and other challenges. This focus on robustness directly impacts a company’s ability to maintain production efficiency, reduce downtime, and minimise long-term operational costs.

Key Elements of Premium Gearbox Durability

1. Material Selection

The material used in a gearbox significantly influences its durability. High-performance materials such as hardened steel, corrosion-resistant alloys, and specialised coatings are essential in premium gearboxes. Gearbox manufacturers use these materials to offer strength and resistance to wear. In extreme environments, where moisture, temperature fluctuations, or chemicals are present, the right material can prevent early failure and extend a gearbox's lifespan.

2. Precision Engineering

Precision is the hallmark of a premium gearbox. The intricacies of gear tooth design, bearings, and housing components must be engineered to exacting standards. Poor tolerances can lead to excessive friction, heat buildup, and accelerated wear. A superior quality gearbox, designed with precision engineering, reduces inefficiencies, ensuring smooth operation even in high-stress environments. This also means fewer vibrations and less noise, further extending the life of the equipment.

3. Heat Resistance

In industries where extreme heat is a constant challenge, a gearbox's ability to dissipate heat is critical. Excessive temperatures can lead to thermal expansion, which affects gear alignment and causes premature wear. Premium gearboxes often incorporate advanced cooling systems or are made from materials that resist thermal degradation. This ensures the gearbox can operate reliably without suffering from heat-related damage.

4. Corrosion Resistance

In sectors like marine or mining, gearboxes are regularly exposed to moisture, chemicals, and salt. Over time, this exposure can lead to corrosion, compromising the gearbox's structure and functionality. Gearbox manufacturers address this by applying corrosion-resistant coatings or using non-corrosive materials like stainless steel or bronze. This added layer of protection ensures the premium gearbox remains intact and functional, even when subjected to harsh environmental conditions.

5. Lubrication Management

Lubrication is critical to reducing friction and wear inside a gearbox. In extreme conditions, regular lubricants can break down, losing their effectiveness. Superior quality gearboxes are designed with advanced lubrication management systems, including seals that prevent contaminants from entering and special lubricants that can withstand extreme temperatures and pressures. These systems ensure the internal components are continuously protected, reducing the chances of mechanical failure.

The Cost Benefits of Investing in a Premium Gearbox

While the initial investment in a premium gearbox might seem higher, the long-term benefits far outweigh the costs. Here’s why:

1. Reduced Downtime

In many industries, unplanned downtime can cost thousands, if not millions, in lost productivity. A high quality gearbox is designed to run for extended periods under extreme conditions without breaking down. This means fewer interruptions and lower maintenance costs, providing businesses with a reliable operation schedule.

2. Lower Maintenance Costs

Durability equates to less frequent repairs and replacements. Manufacturers build premium gearboxes to withstand wear and tear for longer periods, reducing the need for constant maintenance. As a result, businesses can allocate resources more effectively and avoid the costly process of gearbox overhauls or replacements.

3. Improved Efficiency

A premium gearbox, designed for extreme conditions, runs more efficiently. Reduced friction, better alignment, and enhanced lubrication management mean that energy loss is minimised. For businesses, this translates to lower operational costs, as less power is needed to keep machinery running smoothly.

4. Extended Equipment Lifespan

When businesses invest in superior gearbox, they’re also investing in the longevity of their entire system. A reliable gearbox ensures other machinery components are not overworked or prematurely worn out. This extends the overall lifespan of expensive industrial equipment, protecting capital investments.

Choosing the Right Gearbox Manufacturer

Not all gearboxes are created equal. Selecting the right gearbox manufacturer is essential to ensuring durability and performance. Here are key factors to consider when choosing a manufacturer:

1. Experience and Expertise

A reputable manufacturer will have a proven track record in designing solutions for extreme conditions. Look for companies that have extensive experience in industries similar to yours, as they’ll have insights into the unique challenges your operations face.

2. Customisation Options

Every business has specific operational needs. The best manufacturers offer customised solutions that cater to your exact requirements. Whether you need a gearbox with specific cooling mechanisms, corrosion resistance, or power output, premium manufacturers can tailor their designs to meet these demands.

3. After-Sales Support

Even the most durable gearboxes require occasional servicing. The manufacturers who provide strong after-sales support, including maintenance, repairs, and replacement parts, ensure your investment remains in peak condition throughout its lifecycle.

Maximise Efficiency with a Premium Gearbox Built for Extreme Conditions

Is your business operating in challenging environments? Rely on Premium Transmission gearboxes from Santram Engineers. These gearboxes from the leading manufacturing company Premium Transmission Limited are engineered to deliver top performance, even under extreme conditions like high temperatures, heavy loads, or corrosive environments. By investing in a Premium Transmission gearbox, you not only enhance the durability of your machinery but also reduce downtime and long-term maintenance costs.

Santram Engineers is the largest distributor of industrial gearboxes from Premium Transmission Limited. We are also the largest stockist of premium lightweight aluminium gearboxes known as “Altra gearboxes.”

Partner with a company who understands your unique needs and can provide customised solutions that ensure efficiency and longevity. Whether in mining, marine, or industrial settings, a premium gearbox is your key to smoother operations and lower costs. Call us at +91 96247 39393 or email us at sales@santramengineers.com to learn more about our gearbox solutions and how they can improve your bottom line.