Before diving into repairs, it's essential to have a deep understanding of the specific equipment involved. industrial electronics repair often involve complex systems that require specialized knowledge. Familiarize yourself with the technical manuals and schematics of your devices. This foundational knowledge will aid you in diagnosing issues accurately and efficiently, ultimately saving time and money.

Key Areas to Focus On:

Wiring Diagrams: Ensure you comprehend the wiring and connections.

Component Specifications: Know the specifications of individual components, which helps in sourcing affordable replacements.

Common Failures: Learn about frequent issues associated with your equipment to anticipate problems.

2. Implement Preventive Maintenance Practices

One of the most effective ways to reduce repair costs is through preventive maintenance. By regularly checking and servicing equipment, you can identify potential issues before they become significant problems. This proactive approach not only extends the lifespan of your equipment but also minimizes unexpected downtimes.

Preventive Maintenance Tips:

Regular Inspections: Schedule routine inspections to check for wear and tear.

Calibration: Ensure that equipment is calibrated according to manufacturer specifications.

Cleanliness: Maintain a clean environment to prevent dust and debris from affecting performance.

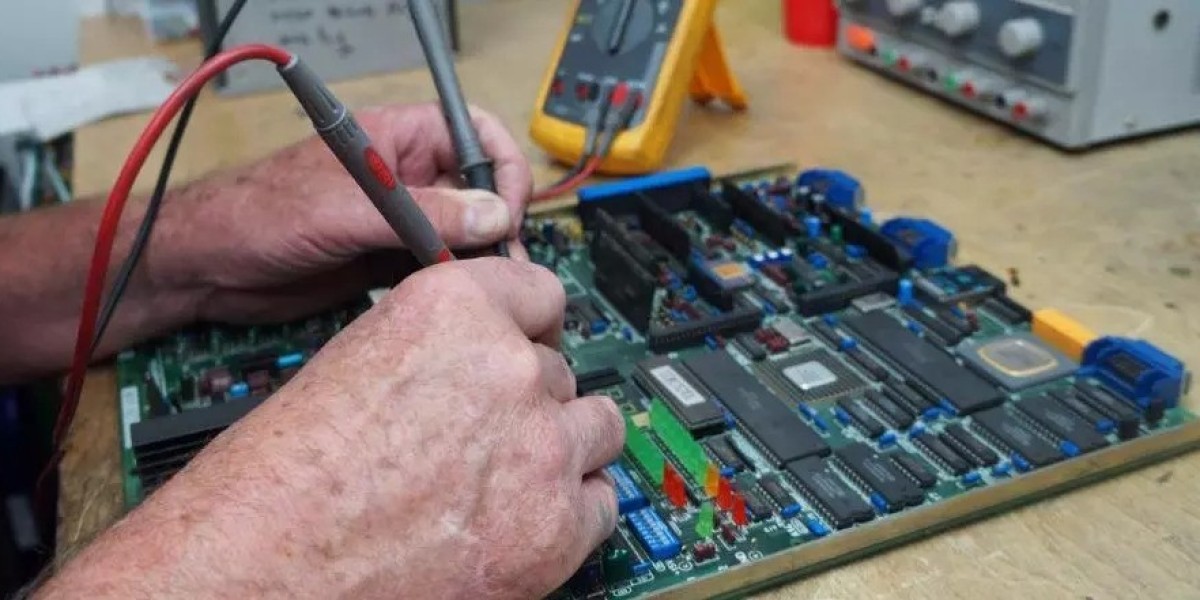

3. Invest in Quality Tools and Equipment

Having the right tools is paramount in ensuring effective repairs. Investing in high-quality tools will make the repair process smoother and more efficient. While it may seem like an upfront expense, the long-term savings from avoiding cheap, unreliable tools are substantial.

Essential Tools for Industrial Electronics Repair:

Digital Multimeter: For accurate electrical measurements.

Oscilloscope: To visualize electrical signals.

Soldering Iron: Essential for repairing circuit boards.

4. Train Your Staff Continuously

Continuous education and training for your repair staff are crucial. As technology evolves, so too do the methods and techniques for repairing equipment. Investing in training not only enhances your team's skills but also ensures that your organization remains competitive.

Training Programs to Consider:

Certification Courses: Enroll staff in certification programs that specialize in industrial electronics.

Workshops: Attend workshops and seminars to stay updated on the latest trends and technologies.

Online Resources: Utilize online platforms for courses and tutorials.

5. Source Parts Wisely

When it comes to sourcing replacement parts, cost-effectiveness is key. OEM parts (Original Equipment Manufacturer) are often more expensive but guarantee compatibility. However, using aftermarket parts can save money without compromising quality if sourced correctly.

Tips for Sourcing Parts:

Research Suppliers: Look for reputable suppliers who offer competitive pricing.

Consider Bulk Purchases: Buying in bulk can significantly reduce costs.

Check Warranties: Always review warranty policies to protect your investment.

6. Keep Detailed Records of Repairs

Maintaining comprehensive records of all repairs and maintenance activities is essential. This practice not only helps track the history of your equipment but also aids in forecasting future maintenance needs.

Benefits of Detailed Record Keeping:

Enhanced Troubleshooting: Quickly identify recurring issues.

Cost Management: Monitor repair costs over time to make informed budget decisions.

Compliance: Ensure adherence to safety regulations and standards.

7. Utilize Technology for Diagnostics

Modern technology offers advanced diagnostic tools that can simplify the repair process. Utilizing software and tools designed for industrial electronics can save time and increase accuracy in troubleshooting.

Popular Diagnostic Tools:

Diagnostic Software: Use software applications to analyze equipment performance and detect faults.

Remote Monitoring Systems: Implement systems that provide real-time data on equipment status.

8. Foster Relationships with Experts

Establishing connections with industry experts can provide valuable insights into best practices for repairs. Collaborating with experienced professionals can help you stay updated on emerging trends and techniques that can improve your operations.

Networking Opportunities:

Industry Conferences: Attend events to meet with industry leaders.

Professional Associations: Join associations related to industrial electronics for networking and knowledge sharing.

Conclusion

By following these expert tips for successful industrial electronics repair, you can ensure that your operations run smoothly while saving money. Implementing a combination of preventive maintenance, staff training, and wise sourcing can significantly enhance your repair processes.

Follow Us More Links:-

Follow Us On Facebook:- https://www.facebook.com/synchronics

Follow Us On Instagram:- https://www.instagram.com/synchronicselectronics/

Follow Us On Linkedin:- https://in.linkedin.com/company/synchronics

Follow Us On Twitter:- https://x.com/synchronics

Add:- 4th Floor, Lotus Enora, Opp. Rutu Villa Bunglows, 24 Mt. Main Road, New Alkapuri, Gotri, Vadodara 390 021, Gujarat (INDIA)

Call Us :- +91-704-308-4455 || +91-704-309-4455 || +91-265-400-1555 || +91-265-356-1183

Email Us:- email@synchronics.co.in