Geo bags, also known as geotextile bags, play a critical role in environmental protection, erosion control, and civil engineering projects. These bags, made from durable geotextile fabrics, are often used in applications such as riverbank protection, coastal engineering, and sand containment for construction. With increased focus on sustainable development and erosion prevention, the demand for geo bags continues to grow, particularly in regions facing environmental challenges. This article explores geo bags' applications, benefits, pricing, and leading manufacturers in India, while also addressing their role in construction and engineering.

Understanding Geo Bags and Geotextile Bags

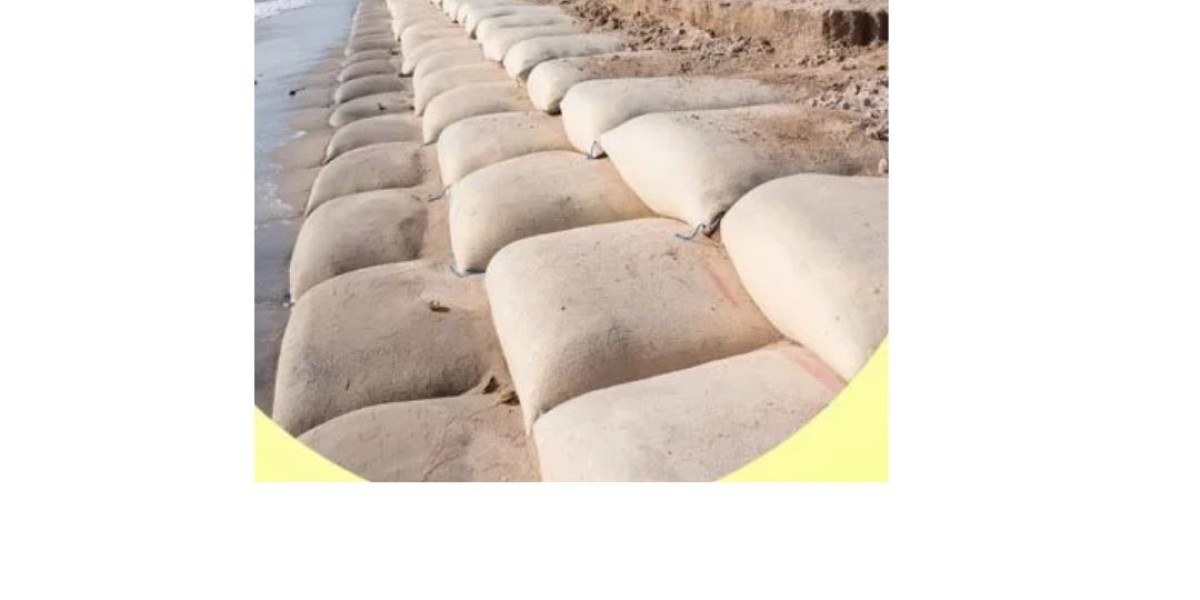

Geo bags, commonly referred to as geotextile bags, are specialized bags made from woven or non-woven geotextile fabric. These bags are filled with sand or soil and strategically placed along coastlines, riverbanks, and construction sites to prevent soil erosion and provide stability to the landscape. The robust design of these bags helps them withstand environmental factors such as water currents, wind, and high pressure, making them an excellent choice for long-term erosion control and sediment retention.

Advantages of Using Geo Bags in Construction

Using geo bags in construction projects offers numerous benefits, making them highly sought after for civil and environmental engineering applications. One significant advantage is their versatility; geo bags can be used in various forms, including sandbags for construction, for shoreline protection, or to prevent soil erosion. Additionally, they are cost-effective and easy to transport and install. The durability of geotextile fabric used in geo bags ensures the bags can withstand harsh weather conditions and heavy-duty applications, minimizing maintenance costs.

Geo Bags for Erosion Control

Erosion control is one of the primary applications for geo bags. When strategically placed along riverbanks, coastlines, and embankments, geo bags provide an effective barrier that prevents soil erosion caused by water currents or wind. By creating a reinforced boundary, geo bags help protect natural landscapes and infrastructure from damage caused by erosion. The longevity and resistance of geotextile bags make them particularly useful for erosion control, offering a sustainable and eco-friendly alternative to traditional erosion prevention methods.

The Role of Sand Bags in Construction Projects

In construction, sandbags play a crucial role in providing structural stability and support. Geo bags filled with sand are commonly used as Sand bags for construction to prevent the shifting of soil and manage water flow in construction sites. These sand bags provide excellent support during the initial stages of construction, helping to secure foundations and prevent landslides. Given their low cost and ease of use, geo bags are an ideal solution for construction companies aiming to achieve stability in challenging terrain or areas prone to soil movement.

Leading Geo Bag Manufacturers in India

India is home to several renowned geo bags manufacturers who produce high-quality geotextile bags for various applications. These manufacturers prioritize product durability, cost-effectiveness, and customization to meet the specific needs of diverse projects. Leading Geo bags manufacturers in India have a wide selection of products that cater to erosion control, environmental engineering, and construction industries. By offering geo bags that meet international quality standards, these manufacturers contribute to India’s growing reputation as a supplier of reliable geotextile solutions.

Geotextile Bags and Their Pricing Factors

The price of geotextile bags depends on several factors, including material quality, bag size, and the specific application for which the bags are intended. High-quality geotextile bags made from durable materials may be priced higher due to their enhanced durability and resilience. The location and supplier also impact Geotextile bags price, as locally sourced materials and established manufacturers may offer cost benefits. Projects requiring large quantities can often benefit from bulk pricing options, which allow for cost savings while ensuring project needs are fully met.

Environmental Benefits of Using Geo Bags

Geo bags offer several environmental benefits, making them an eco-friendly choice for erosion control and infrastructure support. Made from non-toxic materials, geo bags reduce the need for concrete and other non-biodegradable materials, minimizing the environmental impact. Additionally, these bags encourage vegetation growth over time, allowing natural elements to blend with the protective structure. The use of geotextile bags in environmentally sensitive areas helps preserve biodiversity by protecting habitats and preventing soil erosion, ultimately supporting ecological sustainability.

Choosing the Right Geo Bags for Specific Applications

Selecting the right geo bags for a project depends on factors like terrain, environmental conditions, and the specific purpose of use. For example, non-woven geo bags are typically chosen for projects requiring filtration or separation, while woven geo bags are ideal for high-strength applications like riverbank protection. Determining the most suitable type of geo bag ensures optimum performance, cost savings, and longevity. Working closely with geo bags manufacturers in India can also help project managers find the most appropriate geo bag solutions.

Geo Bags as an Alternative to Traditional Erosion Control Methods

In many cases, geo bags offer an innovative and cost-effective alternative to traditional erosion control solutions, such as concrete barriers and metal retaining walls. Compared to conventional methods, geo bags require less time and labor for installation and are more adaptable to natural landscapes. This flexibility allows them to be customized to meet the unique needs of specific environments, particularly in areas where traditional structures may not be feasible. As a result, geo bags have become a preferred choice for both engineers and environmentalists seeking sustainable solutions.

Maintenance and Durability of Geo Bags

One of the most appealing features of geo bags is their low maintenance requirement. The durable geotextile material used to manufacture geo bags is resistant to UV rays, chemicals, and water, making it well-suited for prolonged use in harsh conditions. Unlike concrete structures that may need regular repairs or replacements, geo bags remain effective for years with minimal maintenance. This durability factor, combined with ease of installation, makes geo bags an economical option for long-term erosion control and construction support.

Installation Process for Geo Bags in Construction Sites

The installation of geo bags is straightforward and does not require heavy machinery or extensive labor. For construction sites, these bags are typically filled with sand and stacked or positioned in targeted areas, such as along embankments or slopes. Proper installation is critical to ensuring the geo bags fulfill their intended function, as improper placement can affect their ability to control erosion or stabilize soil. By following standardized installation procedures, construction teams can maximize the effectiveness of sand bags for construction projects.

Future Trends in Geo Bag Usage

As environmental concerns and sustainable engineering practices become more prevalent, the demand for geo bags is expected to increase. Technological advancements in geotextile fabric production are leading to the creation of even more durable and eco-friendly geo bags, further solidifying their role in modern engineering. Additionally, government initiatives and environmental regulations are encouraging the use of eco-friendly materials, making geo bags an attractive option for public and private construction projects. The rise in demand also positions geo bags manufacturers in India to expand their market reach, contributing to global environmental efforts.

Frequently Asked Questions (FAQs)

- What are the main applications of geo bags?

Geo bags are mainly used for erosion control along riverbanks, shorelines, and coastal areas. They are also employed in construction sites to provide structural stability and to prevent soil erosion in environmentally sensitive areas. - How does the price of geotextile bags vary?

The geotextile bags price depends on factors such as material quality, bag size, quantity, and the specific application. High-quality bags designed for long-term use may cost more, but bulk purchases can often result in price discounts. - Why are sand bags used in construction projects?

Sand bags, particularly those made from geotextile fabric, are used in construction to stabilize soil, manage water flow, and prevent erosion. They are durable, cost-effective, and easy to install, making them ideal for supporting foundations and preventing landslides in construction sites.