The UV cured acrylic foam tapes market has seen remarkable growth in recent years, driven by the increasing demand for lightweight and durable materials across various industries. UV-cured acrylic foam tapes, which offer rapid curing, strong adhesion, and excellent performance in harsh conditions, are becoming an essential part of modern manufacturing processes. These advanced adhesive solutions are particularly valued in industries like automotive, aerospace, construction, and electronics, where reducing weight while maintaining high durability is paramount.

The Role of UV Cured Acrylic Foam Tapes

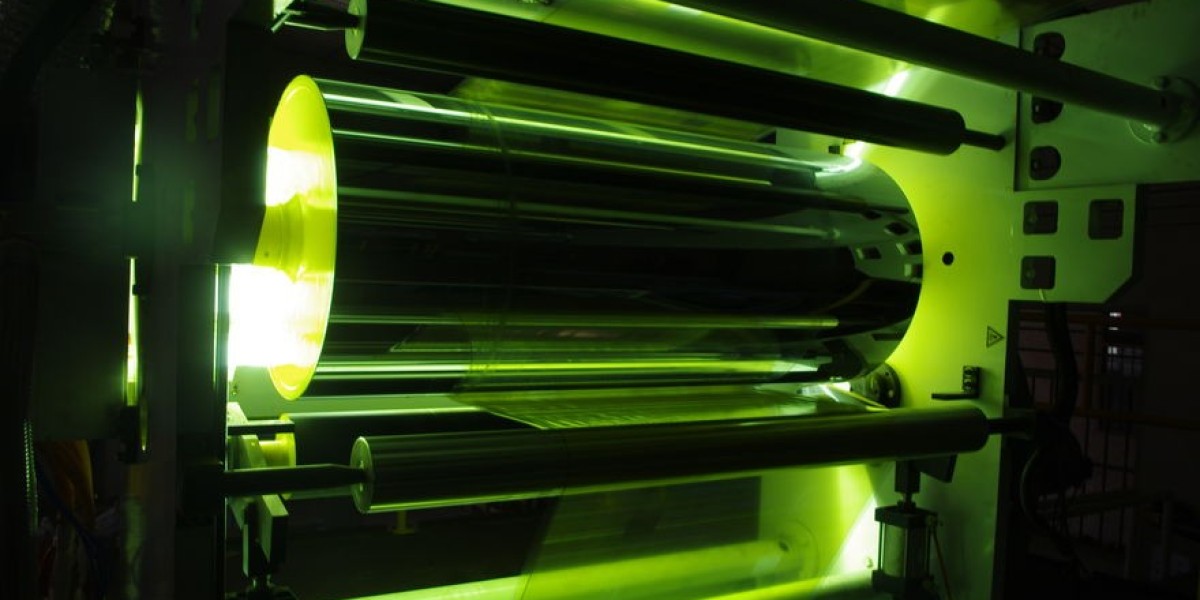

UV-cured acrylic foam tapes combine the superior bonding characteristics of acrylic foam with the efficiency of UV curing technology. The core of these tapes is made of a high-density acrylic foam, which provides shock absorption, sound insulation, and thermal resistance. The adhesive layer applied to the foam is cured using ultraviolet (UV) light, making it set almost instantly after exposure, thus offering a highly efficient bonding process.

One of the main reasons UV-cured acrylic foam tapes are increasingly sought after is their ability to bond a wide range of substrates, including metals, plastics, glass, and composites. Unlike traditional adhesives that require long curing times or heat-based processes, UV curing provides a rapid and energy-efficient way to bond materials. This quick setting feature is particularly valuable in industries where speed, precision, and high-volume production are key considerations.

The Growing Demand for Lightweight Materials

Across a range of industries, the push for lighter, more efficient products has never been more pronounced. From automotive manufacturers focusing on fuel-efficient vehicles to electronics companies producing smaller, sleeker devices, the demand for lightweight materials is driving innovation in adhesive technologies. UV-cured acrylic foam tapes are ideally positioned to meet this demand due to their combination of low weight, high strength, and durability.

In the automotive sector, manufacturers are increasingly turning to lightweight materials to reduce vehicle weight and improve fuel efficiency. Reducing weight helps improve performance, decrease emissions, and extend the lifespan of the vehicle. UV-cured acrylic foam tapes are used to replace traditional mechanical fasteners, such as screws, rivets, and welding, which not only add unnecessary weight but can also increase the complexity and cost of the manufacturing process. By using these tapes, automotive manufacturers can bond components securely while keeping the overall weight of the vehicle low.

In the aerospace industry, where weight reduction directly correlates with fuel savings and operational efficiency, the demand for lightweight bonding solutions is even more critical. Aircraft manufacturers are increasingly using UV-cured acrylic foam tapes to bond critical components like windows, panels, and interior elements. These tapes offer superior durability while contributing to the overall lightweight design of aircraft, helping airlines reduce operational costs.

Market Scenario: Shifting Towards Sustainable, High-Performance Solutions

The global market for UV-cured acrylic foam tapes is being shaped by several broader trends, with sustainability, performance enhancement, and cost-efficiency being at the forefront. As industries move toward sustainable practices and more energy-efficient manufacturing methods, UV-cured acrylic foam tapes present an attractive solution.

1. Environmental Sustainability

The increasing emphasis on sustainability is one of the key drivers of growth in the UV-cured acrylic foam tapes market. Manufacturers are increasingly prioritizing solutions that are environmentally friendly, and UV-cured acrylic foam tapes meet these demands in several ways. First, they are solvent-free, meaning they do not emit volatile organic compounds (VOCs) during application, unlike many traditional adhesives. This makes them a more environmentally responsible choice, particularly in industries subject to stringent environmental regulations.

2. Demand for Higher Durability and Performance

As industries focus on improving the reliability and longevity of their products, the need for adhesives that can withstand extreme conditions such as high temperatures, humidity, and mechanical stress has increased. UV-cured acrylic foam tapes are known for their exceptional performance in harsh environments. Their ability to provide high adhesion strength while withstanding temperature variations and physical stress makes them ideal for demanding applications in sectors like automotive, aerospace, and construction.

In the automotive industry, for example, UV-cured acrylic foam tapes are used for bonding exterior panels, windows, and trim, where the bonds must endure extreme temperatures, vibrations, and weather conditions. In the electronics sector, these tapes are used in devices that experience frequent handling or exposure to varying environmental conditions, providing long-lasting, secure bonds.

3. Cost-Efficiency and Productivity Gains

The adoption of UV-cured acrylic foam tapes also contributes to cost savings for manufacturers. Traditional adhesive methods often require longer processing times, as well as additional labor and energy costs. UV curing, on the other hand, enables faster processing times, with the adhesive setting almost instantly upon exposure to UV light. This rapid curing process improves production efficiency, reduces the time to market for products, and cuts down on the need for extensive inventory management.

The Future of UV Cured Acrylic Foam Tapes

As the demand for lightweight and durable materials continues to grow across industries, the future of UV-cured acrylic foam tapes looks promising. The market is expected to experience continued expansion as manufacturers seek innovative bonding solutions that align with current trends in sustainability, automation, and high-performance design.

1. Technological Innovations

Ongoing research and development efforts are likely to lead to further advancements in UV cured acrylic foam tape technology. For example, innovations in adhesive chemistry may result in tapes with even greater resistance to extreme conditions, or with the ability to bond a wider range of materials, including more advanced composites and substrates. These developments will expand the range of applications for UV cured acrylic foam tapes, making them even more versatile across industries.

2. Expansion into Emerging Markets

In addition to the established markets in North America, Europe, and Asia-Pacific, the UV-cured acrylic foam tapes market is expected to see significant growth in emerging markets. As countries in Latin America, the Middle East, and Africa modernize their manufacturing sectors, the demand for advanced, high-performance bonding solutions will rise. The automotive and electronics industries in these regions are particularly poised for growth, driven by the increasing adoption of new technologies and consumer demands for lightweight and durable products.