Geocells are an innovative and flexible cellular confinement system used in various civil engineering and environmental projects. Geocells are often used to enhance soil stability, improve load distribution, and support the construction of roads, embankments, and more. Designed to provide high strength and durability, geocells help prevent soil erosion and are also commonly applied in applications requiring load-bearing support.

What Are Geocells Made Of and How Do They Work?

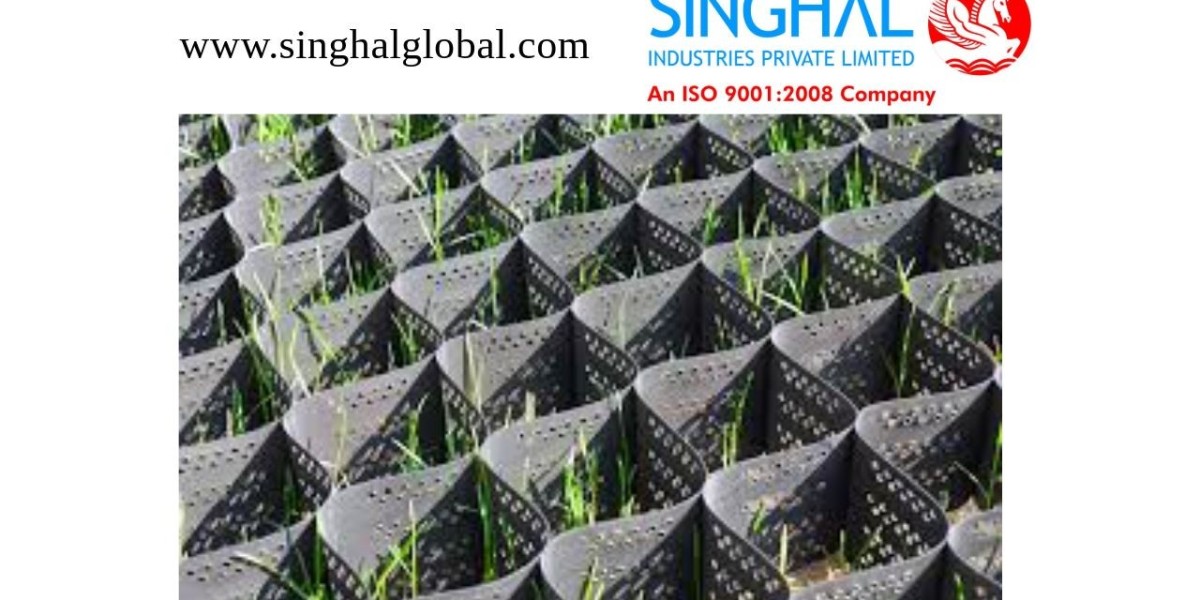

Geocells are typically manufactured from high-density polyethylene (HDPE), a durable material resistant to environmental and chemical degradation. The structure of a geocell is a honeycomb-like grid that confines the soil or other fill materials within its compartments. When filled and compacted, geocells distribute loads more evenly across the surface, making them ideal for load-supporting applications. The confinement offered by geocells enhances the shear strength of the infill material, allowing it to resist greater pressures.

Applications of Geocells

Geocells have a wide range of applications in infrastructure, environmental, and landscape development projects. In road construction, for example, geocells provide a stabilized foundation for pavement and gravel surfaces, reducing the required thickness of construction layers. Geocell manufacturers play an important role in producing various grades and types suited to different load requirements and environmental conditions. This makes them invaluable for applications where soil quality is suboptimal or where soil erosion is a significant concern.

Benefits of Geocells in Construction Projects

Using geocells in construction projects provides several significant benefits, including improved load distribution, enhanced soil stabilization, and reduced erosion. For geocell road construction in India, geocells are especially valuable as they can make roads more resilient and reduce the need for frequent maintenance. Geocells can also reduce the construction time, as they provide stability with fewer materials. By distributing loads evenly, they help avoid rutting and differential settlement, two common problems in roadway surfaces.

Environmental Benefits of Geocells

Geocells contribute to environmental sustainability by minimizing the need for large quantities of non-renewable resources in construction. Because they reduce the volume of fill material needed, geocells lead to a reduction in emissions from transporting materials. They are also effective in erosion control and help in the revegetation of slopes and embankments. This ecological application of geocells makes them suitable for eco-sensitive zones, allowing natural vegetation to flourish while still providing structural stability.

Geocells in Road Construction

Geocells are widely used in Geocell road construction in India, especially for rural roads, highways, and railways where soil quality is variable. In these projects, geocells act as a reinforcement layer, providing additional strength to the subgrade. This prevents the surface from shifting or becoming unstable under heavy loads. Using geocells in road construction not only enhances road durability but also improves safety by providing a smooth, stable surface less prone to potholes and wear.

Geocells for Driveway Applications

For residential and commercial driveways, geocells offer a cost-effective and durable solution. Geocell driveway exporters provide tailored options for driveways that need reinforcement without requiring a thick base layer. Driveways made with geocells offer improved drainage and stability, preventing issues like cracking and subsidence. They are particularly beneficial in regions with frequent rain or poor soil conditions, as the structure of geocells allows water to flow through, minimizing pooling and erosion.

Geocells for Erosion Control

One of the most common uses of geocells is erosion control on slopes, embankments, and riverbanks. Geocells help retain soil and reduce erosion caused by wind and water by providing a stable structure for vegetation to take root. This application is especially beneficial in coastal areas and areas prone to heavy rainfall, where erosion can cause landslides and other hazards. By stabilizing the soil, geocells provide long-term protection against erosion and promote healthier ecosystems.

Advantages of Using Geocells for Slope Reinforcement

Geocells are widely applied in slope reinforcement projects due to their ability to improve slope stability and protect against erosion. They reinforce the soil, allowing for greater slope angles without compromising stability. This is particularly valuable for steep slopes, embankments, and hillside developments, where soil erosion can otherwise lead to major issues. The use of geocells reduces the need for retaining walls or other rigid support systems, offering a flexible, environmentally friendly alternative.

Geocells for Load Support

Another critical application of geocells is load support. In areas that bear heavy loads, such as parking lots, storage yards, and industrial floors, geocells prevent ground shifting and subsidence. They allow the surface to bear more weight without requiring extensive foundational reinforcement. By using geocells, construction projects can reduce overall material costs and extend the lifespan of load-bearing surfaces. This application is particularly useful in areas with soft or unstable soil, where other methods might be less effective.

Ease of Installation and Cost-Effectiveness of Geocells

One of the key advantages of geocells is their ease of installation. They are supplied in a collapsed form and can be expanded on-site, making them convenient to transport and handle. Installation requires minimal equipment, which speeds up the construction process and reduces labor costs. Additionally, geocells reduce the need for extensive excavation, as they provide stability with a thinner base layer than conventional methods. This makes them a cost-effective choice for both large-scale and small-scale projects.

Factors to Consider When Choosing Geocells

When selecting geocells for a project, it’s important to consider factors such as load requirements, environmental conditions, and soil type. Geocells come in different grades and cell sizes, which can be selected based on the specific needs of the application. Working with reputable Geocell manufacturers ensures that the product meets industry standards for durability and effectiveness geocell driveway exporters. Quality geocells can make a significant difference in the longevity and stability of the project.

Frequently Asked Questions (FAQ)

1. What is the primary purpose of using geocells in construction?

The primary purpose of geocells is to stabilize the soil, improve load distribution, and prevent soil erosion. Geocells provide structural support to load-bearing surfaces and reinforce slopes and embankments, making them suitable for various construction projects.

2. How do geocells contribute to road construction projects?

Geocells are used in road construction to stabilize the subgrade layer, enhancing the durability and safety of the road. They reduce the required thickness of base layers, improve load distribution, and protect the surface from issues like rutting and cracking.

3. Are geocells environmentally friendly?

Yes, geocells are environmentally friendly. By reducing the need for excess fill materials and preventing erosion, they minimize environmental impact. Geocells also promote vegetation growth in erosion control applications, helping to restore ecosystems.

4. Can geocells be used for residential driveways?

Yes, geocells are suitable for residential driveways as they offer stability and durability. They help distribute weight evenly, prevent surface shifting, and reduce maintenance needs, making them an excellent choice for long-lasting driveways.